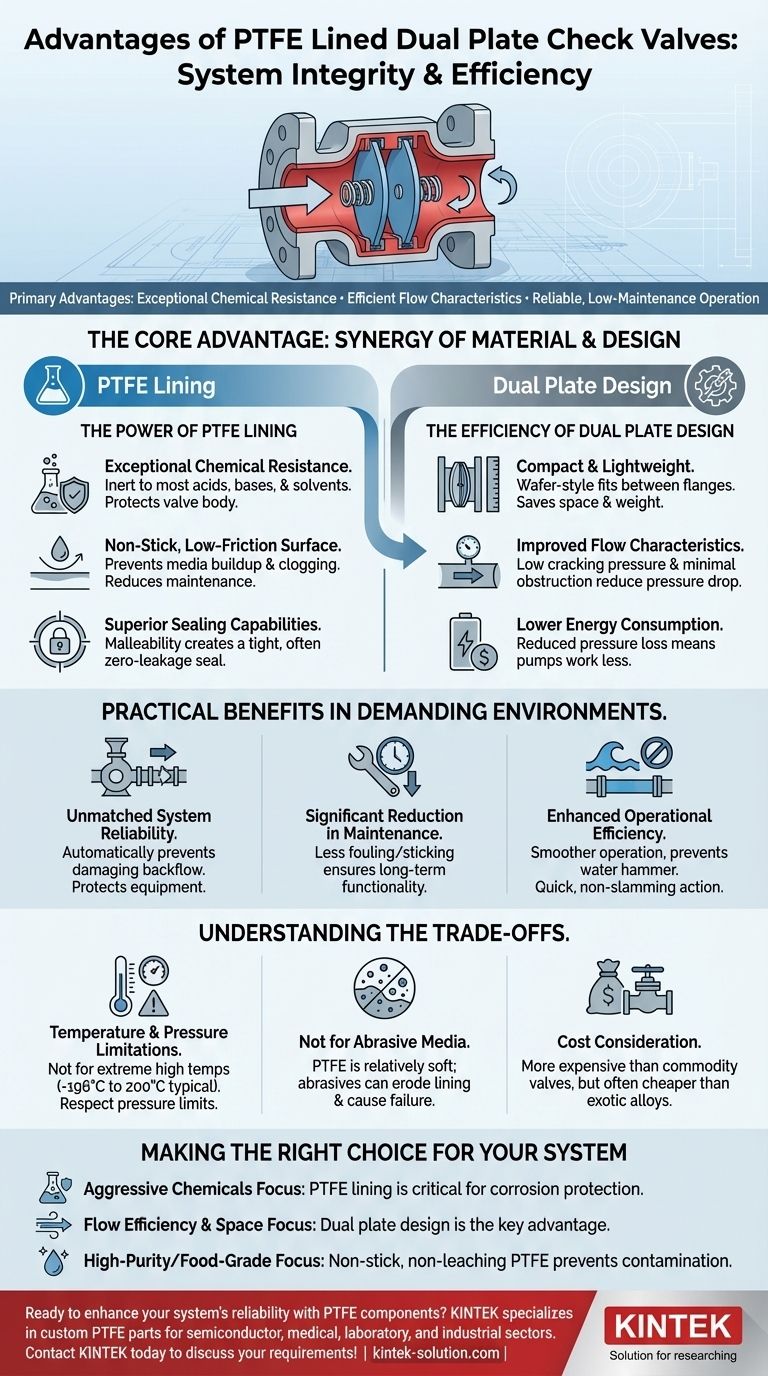

The primary advantages of PTFE lined dual plate check valves are their exceptional resistance to chemical corrosion, their efficient and low-impact flow characteristics, and their reliable, low-maintenance operation. This unique combination of a chemically inert lining and a high-performance valve design makes them ideal for demanding industrial applications.

By fusing the non-stick, corrosion-proof properties of Polytetrafluoroethylene (PTFE) with the compact, efficient mechanics of a dual plate check valve, you get a solution that ensures both system integrity and operational efficiency when handling aggressive or high-purity media.

The Core Advantage: Combining Material and Design

The value of these valves comes from the synergy between two key elements: the PTFE lining that protects the valve's internal components and the dual plate mechanism that controls flow.

The Power of a PTFE Lining

PTFE, commonly known by the brand name Teflon, is a high-performance fluoropolymer. When used as a valve lining, it provides several distinct benefits.

It offers exceptional chemical resistance, making it virtually inert to most acids, bases, and solvents. This allows standard materials like cast iron or carbon steel to be used for the valve body, providing a cost-effective solution for highly corrosive services.

The material’s non-stick, low-friction surface prevents media from building up inside the valve. This property is critical for reducing clogging, minimizing maintenance, and ensuring consistent performance over time.

Finally, PTFE provides superior sealing capabilities. Its malleability allows it to create a tight seal that can often achieve zero leakage, protecting downstream equipment and preventing product contamination.

The Efficiency of the Dual Plate Design

The dual plate (or dual door) check valve design is inherently more efficient than older designs like swing check valves.

These valves are significantly more compact and lightweight. Their wafer-style body fits between two pipe flanges, reducing installation space, weight, and material cost.

They provide improved flow characteristics. The two spring-loaded plates, or doors, open with minimal pressure (low "cracking pressure") and create less obstruction in the flow path, reducing pressure drop across the valve.

This efficiency translates directly to lower energy consumption. Because there is less pressure loss, pumps do not have to work as hard to move fluid through the system, saving operational costs.

Practical Benefits in Demanding Environments

The combination of PTFE and the dual plate design solves critical problems in industries like chemical processing, pharmaceuticals, and water treatment.

Unmatched System Reliability

The primary function of any check valve is to prevent damaging backflow. This design accomplishes that automatically and reliably, protecting pumps and other critical equipment.

The non-stick PTFE lining and simple mechanics lead to a significant reduction in maintenance needs. There is less potential for fouling or sticking, which ensures long-term, predictable functionality.

Enhanced Operational Efficiency

The low cracking pressure and minimal fluid obstruction ensure smoother system operation. This reduces the potential for water hammer, a destructive pressure surge that can damage pipelines.

The valve's design ensures a quick-closing, non-slamming action. As flow stops, the springs help close the two plates quickly and gently before significant reverse flow can occur.

Understanding the Trade-offs

While highly effective, these valves are not a universal solution. Understanding their limitations is key to proper application.

Temperature and Pressure Limitations

While PTFE has a wide operating temperature range (typically -196°C to 200°C), it is not suitable for the extreme high-temperature services that all-metal valves can handle. The lining also imposes pressure limits that must be respected.

Not for Abrasive Media

PTFE is a relatively soft material. It excels with corrosive liquids and gases but can be quickly damaged by abrasive slurries or media containing hard particulates, which can erode the lining and cause valve failure.

Cost Consideration

A PTFE lined valve is a specialized component. It is generally more expensive than a standard commodity check valve but often provides a more cost-effective solution than building the entire valve from an exotic alloy like Hastelloy or Titanium.

Making the Right Choice for Your System

Selecting the correct valve requires matching its strengths to your primary operational goal.

- If your primary focus is handling aggressive chemicals: The chemically inert PTFE lining is the most critical feature, protecting your system from corrosion.

- If your primary focus is maximizing flow efficiency and saving space: The compact, low-pressure-drop dual plate design is the key advantage.

- If your primary focus is ensuring high-purity or food-grade processes: The non-stick, non-leaching properties of the PTFE lining prevent contamination and buildup.

Choosing a PTFE lined dual plate check valve is an investment in your system's long-term reliability and operational integrity.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Resistance | PTFE lining is inert to most acids, bases, and solvents, protecting valve internals from corrosion. |

| Non-Stick Surface | Prevents media buildup and clogging, minimizing maintenance needs. |

| Compact & Lightweight | Dual plate wafer design saves space and reduces weight compared to swing check valves. |

| Efficient Flow | Low cracking pressure and minimal pressure drop lower energy consumption. |

| Quick, Non-Slamming Closure | Spring-assisted plates close rapidly to prevent backflow and water hammer. |

Ready to enhance your system's reliability and efficiency with high-performance PTFE components?

KINTEK specializes in the precision manufacturing of custom PTFE parts, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment is protected from corrosive media while maximizing operational uptime.

We offer custom fabrication from prototypes to high-volume orders, delivering the exact solution your application demands.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments