In industrial applications, PTFE ball valves are chosen for their exceptional chemical resistance, low-friction operation, and ability to perform reliably across a wide temperature range. This unique combination of properties makes them a default choice for handling aggressive, corrosive, or high-purity media where other materials would fail.

The core advantage of a PTFE ball valve is not a single feature, but its holistic value proposition: it provides an extremely reliable, chemically inert, and low-maintenance sealing solution for demanding environments, from cryogenics to pharmaceutical processing.

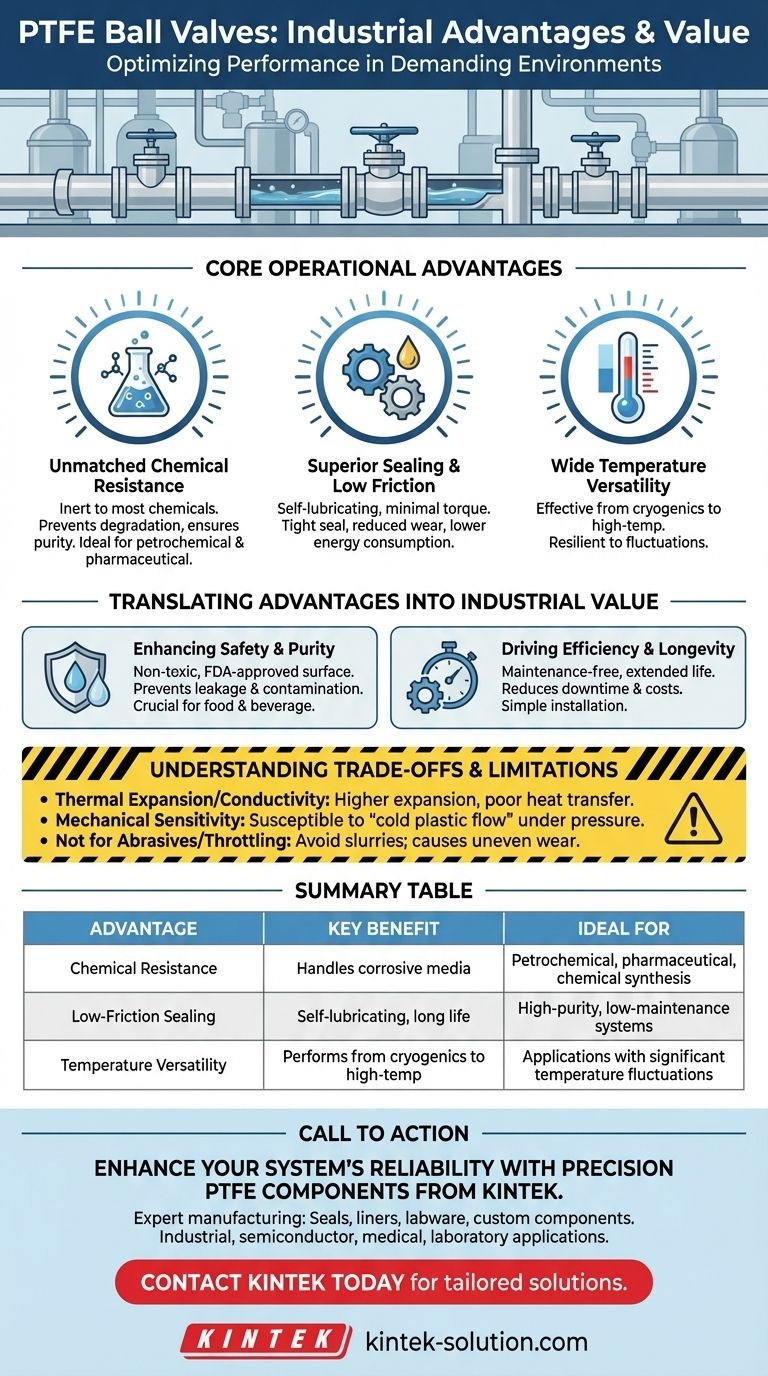

The Core Operational Advantages of PTFE

The material properties of Polytetrafluoroethylene (PTFE) are the foundation of its performance in industrial valves. These characteristics directly translate into significant operational benefits.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and solvents. This makes it an ideal material for wetted parts in valves handling corrosive media.

This resistance prevents valve degradation and ensures the purity of the medium, which is critical in petrochemical, pharmaceutical, and chemical synthesis applications.

Superior Sealing and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property means no external lubrication is required for the valve's operation.

The result is a tight, reliable seal that can be achieved with minimal torque, reducing wear on valve components and lowering the energy consumption of actuation systems.

Wide Temperature Versatility

PTFE maintains its properties across an exceptionally broad temperature spectrum. This allows it to be used effectively in both high-temperature processes and cryogenic applications.

Few other valve materials offer this level of versatility, making PTFE a go-to solution for systems with significant temperature fluctuations.

Translating Advantages into Industrial Value

These inherent material properties create tangible value in industrial settings, primarily by enhancing safety, efficiency, and overall system longevity.

Enhancing Safety and Purity

The superior sealing capability of PTFE prevents the escape of hazardous or volatile materials, dramatically improving plant safety.

Furthermore, its non-toxic, non-stick surface is FDA-approved, preventing material accumulation and contamination. This is an essential requirement in food processing, beverage, and pharmaceutical industries.

Driving Efficiency and Longevity

Because they require no lubrication and resist wear, PTFE ball valves offer a long, maintenance-free service life. This reduces downtime and lowers long-term operational costs.

Their relatively lightweight construction and simple design also make them easier and faster to install compared to more complex valve assemblies.

Cost-Effectiveness

When compared to exotic metal alloys or other specialized valve types designed for corrosive service, PTFE ball valves often represent a more cost-effective solution without compromising performance.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. An objective assessment requires understanding its limitations to avoid misapplication.

Thermal Expansion and Conductivity

PTFE has a significantly higher coefficient of thermal expansion than metals. This can lead to sealing issues in applications with rapid, extreme temperature cycling.

It also has poor thermal conductivity, which must be considered in the overall design of a thermal processing system.

Mechanical Sensitivity

The material is relatively soft and can be susceptible to "cold plastic flow" under high pressure. The sealing surfaces can also be damaged by scratches or abrasive particles.

Once scratched, the reliability of the seal can be permanently compromised, necessitating replacement.

Unsuitability for Certain Applications

PTFE ball valves are not recommended for handling abrasive media like slurries, as the particles will quickly damage the soft seats.

They are also poorly suited for applications requiring sustained throttling or flow regulation, as this can cause uneven wear and premature failure of the seating material.

Making the Right Choice for Your Application

Selecting the correct valve requires aligning its capabilities with your primary operational goal.

- If your primary focus is handling corrosive or high-purity media: PTFE is an industry standard due to its unmatched chemical inertness and non-contaminating surface.

- If your primary focus is operational efficiency and low maintenance: The self-lubricating, low-torque nature of PTFE reduces energy costs and extends the valve's service life.

- If your application involves abrasive slurries or sustained throttling: You must consider alternative valve designs with harder, more durable seating materials better suited for these conditions.

By understanding both its powerful advantages and clear limitations, you can confidently deploy PTFE ball valves to enhance safety and efficiency in the right industrial applications.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Handles corrosive media without degradation | Petrochemical, pharmaceutical, chemical synthesis |

| Low-Friction Sealing | Self-lubricating, minimal torque, long service life | High-purity, low-maintenance systems |

| Temperature Versatility | Performs from cryogenics to high-temperature processes | Applications with significant temperature fluctuations |

Enhance your system's reliability with precision PTFE components from KINTEK.

Our expertise in manufacturing high-performance PTFE seals, liners, labware, and custom components ensures your industrial, semiconductor, medical, or laboratory applications run safely and efficiently. We specialize in custom fabrication from prototypes to high-volume orders, delivering the chemical resistance and durability your operations demand.

Contact KINTEK today to discuss your specific needs and get a tailored solution!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained