In essence, modified PTFE enhances specific physical properties where the original material falls short. Compared to virgin PTFE, modified versions offer significantly improved resistance to cold flow (creep), provide smoother and less porous surfaces, and can be welded, all while maintaining excellent chemical resistance and thermal stability.

The core decision between virgin and modified PTFE is a trade-off between absolute purity and superior mechanical performance. While virgin PTFE is the benchmark for purity, modified PTFE was engineered to solve its primary structural weaknesses, making it the better choice for most demanding sealing and mechanical applications.

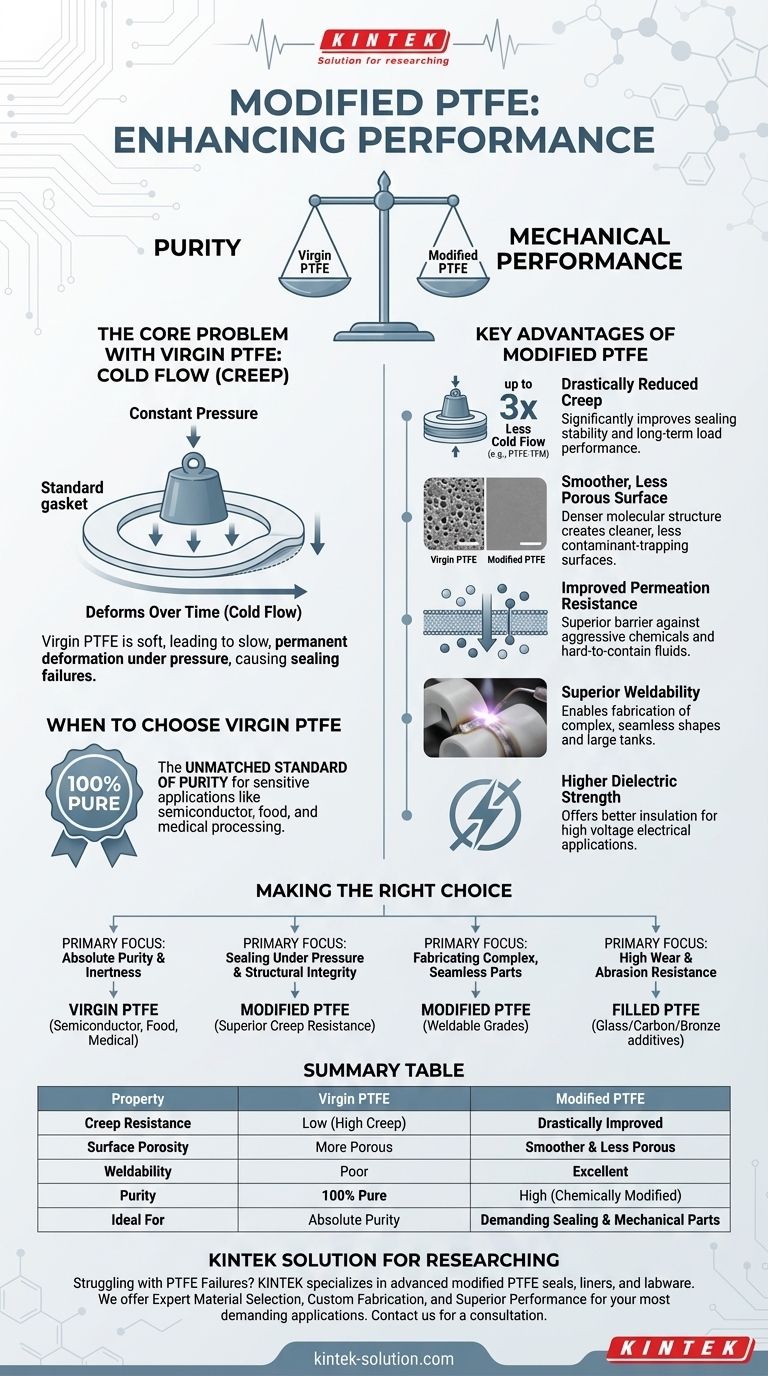

The Core Problem with Virgin PTFE: Cold Flow

To understand the value of modified PTFE, we must first address the primary limitation of its virgin form.

What is Cold Flow (Creep)?

Virgin PTFE is a relatively soft material. When a constant pressure is applied—such as in a gasket or a valve seat—the material will slowly and permanently deform over time. This phenomenon is known as cold flow or creep.

The Impact on Sealing and Structural Integrity

This slow deformation can lead to a loss of sealing pressure, causing leaks in flanges and fittings. In structural components, it can result in a loosening of tolerances and eventual failure of the part.

Key Mechanical and Surface Enhancements of Modified PTFE

Modified PTFE grades are specifically designed to counteract the inherent weaknesses of the virgin polymer.

Drastically Reduced Creep and Cold Flow

The most significant advantage is a dramatic improvement in creep resistance. Certain chemically modified grades, like PTFE-TFM, reduce cold flow by a factor of three, ensuring long-term stability under load.

Smoother, Less Porous Surfaces

The modification process results in a denser molecular structure. This creates a smoother, less porous machined surface that is less likely to trap contaminants, making it ideal for high-purity or sanitary applications where cleanability is critical.

Improved Permeation Resistance

The denser material structure also makes it more difficult for gases and liquids to permeate through the material. This is a crucial benefit when handling aggressive or hard-to-contain chemicals.

Superior Weldability

Unlike virgin PTFE, which is notoriously difficult to join, certain modified grades have excellent weldability. This allows for the fabrication of complex shapes and tank liners that would be impossible with the standard material.

Higher Dielectric Strength

For electrical applications, modified PTFE often exhibits a higher dielectric strength, providing superior insulation against high voltages compared to its virgin counterpart.

Understanding the Trade-offs: When to Choose Virgin PTFE

Despite these powerful advantages, modified PTFE is not a universal replacement. Virgin PTFE remains the superior choice in specific contexts.

The Unmatched Standard of Purity

Virgin PTFE is 100% pure polytetrafluoroethylene with no additives. This absolute purity is non-negotiable in sensitive applications like semiconductor manufacturing, food processing systems, and precision scientific equipment where any leachable could cause contamination.

Predictable and Proven Properties

For decades, engineers have designed around the well-documented properties and limitations of virgin PTFE. In applications where its known characteristics are sufficient, there is often no compelling reason to introduce the variable of a modified grade.

Potential Impact of Modifiers and Fillers

While chemically modified PTFE maintains broad chemical resistance, introducing fillers (like glass, carbon, or bronze) to create "filled PTFE" fundamentally changes the material. These fillers enhance hardness and wear resistance but may reduce chemical compatibility or alter other core properties.

Making the Right Choice for Your Application

Selecting the correct material requires identifying the primary challenge your application faces.

- If your primary focus is absolute purity and chemical inertness: Virgin PTFE is the only reliable choice for applications in food, medical, and semiconductor industries.

- If your primary focus is sealing under pressure or structural integrity: Modified PTFE is unequivocally superior due to its vastly improved creep resistance.

- If your primary focus is fabricating complex, seamless parts: A weldable grade of modified PTFE provides design freedom that virgin PTFE cannot match.

- If your primary focus is high wear and abrasion resistance: A filled PTFE grade, which incorporates additives like glass or bronze, is required to achieve the necessary hardness and durability.

Ultimately, the choice depends on identifying whether your application is limited by PTFE's inherent mechanical shortcomings or if it absolutely requires its unmatched purity.

Summary Table:

| Property | Virgin PTFE | Modified PTFE |

|---|---|---|

| Creep / Cold Flow Resistance | Low (High Creep) | Drastically Improved |

| Surface Porosity | More Porous | Smoother & Less Porous |

| Weldability | Poor | Excellent |

| Purity | 100% Pure (Unmatched) | High (Chemically Modified) |

| Ideal For | Absolute Purity Applications (Semiconductor, Medical) | Demanding Sealing & Mechanical Parts |

Struggling with PTFE Sealing Failures or Complex Part Design?

KINTEK specializes in manufacturing precision PTFE components, including advanced modified PTFE seals, liners, and labware. We help engineers in the semiconductor, medical, laboratory, and industrial sectors overcome the limitations of virgin PTFE.

We provide:

- Expert material selection to solve cold flow, improve sealing, and enable welding.

- Custom fabrication from prototypes to high-volume production.

- Superior performance for your most demanding applications.

Let our experts help you select the right material and manufacture a superior solution. Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability