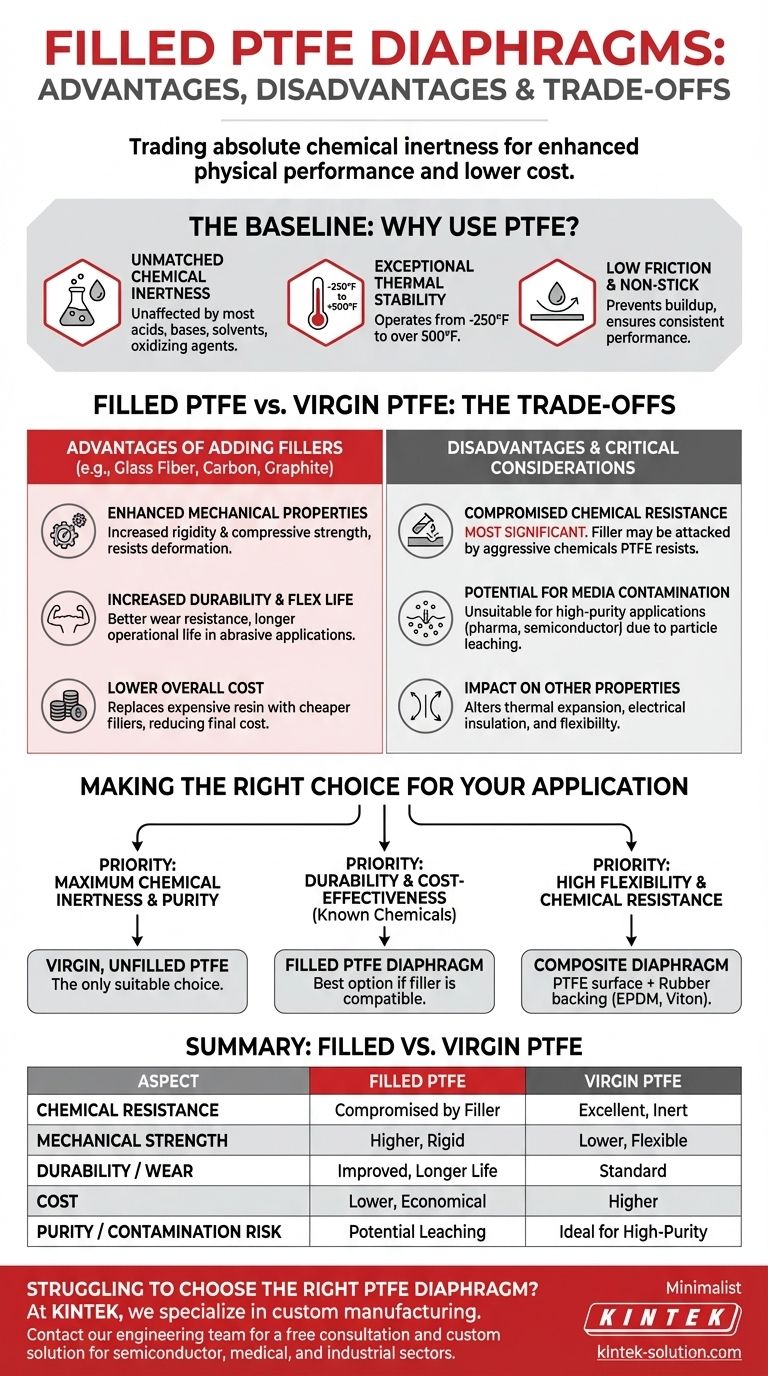

In short, filled PTFE diaphragms offer significant advantages in mechanical strength, durability, and cost-effectiveness compared to their virgin PTFE counterparts. However, these improvements come with a critical trade-off: the filler material can reduce the diaphragm's overall chemical resistance, making it unsuitable for certain aggressive media.

The core decision hinges on a single principle: you are trading the absolute chemical inertness of virgin PTFE for enhanced physical performance and a lower price point. The specific filler used is the most important variable in this equation.

The Baseline: Why Use PTFE in the First Place?

Before analyzing fillers, it's essential to understand why Polytetrafluoroethylene (PTFE) is a benchmark material for demanding applications. Its inherent properties set the standard.

Unmatched Chemical Inertness

PTFE is famously inert, remaining unaffected by nearly all industrial acids, bases, solvents, and oxidizing agents. This makes it the default choice for handling aggressive or high-purity fluids.

Exceptional Thermal Stability

With an operational temperature range from -250°F to over 500°F (-156°C to 260°C), PTFE diaphragms maintain their integrity in extreme thermal conditions where other materials would fail.

Low Friction and Non-Stick Surface

PTFE's extremely low coefficient of friction and non-adhesive surface prevent material buildup and contamination. This ensures consistent performance and reduces maintenance.

The Advantages of Adding Fillers to PTFE

While virgin PTFE is exceptional, it has limitations in mechanical toughness. Fillers are introduced to address these specific weaknesses.

Enhanced Mechanical Properties

Adding fillers like glass fiber, carbon, or graphite significantly increases the diaphragm's rigidity and compressive strength. This makes it more resistant to deformation under pressure.

Increased Durability and Flex Life

Filled PTFE diaphragms exhibit better wear resistance and a longer operational life in applications involving frequent flexing and abrasive media. The filler material reinforces the polymer structure.

Lower Overall Cost

PTFE resin is a premium, expensive material. Displacing a portion of it with less expensive filler materials can substantially lower the final cost of the diaphragm, making it a more economical choice.

Understanding the Trade-offs and Disadvantages

The benefits of filled PTFE are clear, but they do not come without potential downsides that are critical to consider. The choice of filler is everything.

The Critical Factor: Compromised Chemical Resistance

This is the most significant disadvantage. While the PTFE itself remains inert, the filler material may not be. An aggressive chemical that doesn't affect PTFE could attack the filler, leading to diaphragm failure.

Potential for Media Contamination

In high-purity applications, such as pharmaceuticals or semiconductor manufacturing, the filler material itself could potentially leach particles into the process fluid. This makes virgin PTFE the only acceptable option in such cases.

Impact on Other Properties

The addition of a filler changes the diaphragm's properties across the board. For example, it can alter the coefficient of thermal expansion, electrical insulation properties, and overall flexibility.

Making the Right Choice for Your Application

Selecting the correct diaphragm material requires a clear understanding of your operational priorities. Your choice must align with the specific demands of your system.

- If your primary focus is maximum chemical inertness and purity: Virgin, unfilled PTFE is the only suitable choice.

- If your primary focus is durability and cost-effectiveness in a known chemical environment: A filled PTFE diaphragm is likely the best option, provided you confirm the filler's compatibility with your media.

- If your primary focus is high flexibility combined with chemical resistance: Consider a composite diaphragm, which pairs a PTFE wetted surface with a flexible rubber backing like EPDM or Viton.

Ultimately, the right diaphragm balances chemical compatibility against the mechanical demands of your application.

Summary Table:

| Aspect | Filled PTFE | Virgin PTFE |

|---|---|---|

| Chemical Resistance | May be compromised by filler | Excellent, inert to most media |

| Mechanical Strength | Higher, more rigid | Lower, more flexible |

| Durability / Wear | Improved, longer flex life | Standard |

| Cost | Lower, more economical | Higher |

| Purity / Contamination Risk | Potential for filler leaching | Ideal for high-purity applications |

Struggling to choose the right PTFE diaphragm for your specific media and pressure requirements?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom diaphragms for the semiconductor, medical, laboratory, and industrial sectors. Our experts can help you navigate the critical trade-offs between virgin and filled PTFE to ensure optimal performance, durability, and chemical compatibility for your application.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a diaphragm that perfectly balances your needs for chemical resistance, mechanical strength, and cost.

Contact our engineering team today for a free consultation and let us provide a solution tailored to your unique challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What role does PTFE play in football field maintenance? Boost Equipment Performance & Field Quality

- Can machined PTFE parts be customized? Achieve Precision Solutions for Demanding Applications

- How does PTFE's friction coefficient benefit dynamic sealing applications? Enhance Efficiency and Longevity

- How do fillers enhance PTFE's properties? Unlock Superior Wear Resistance & Stability

- How do PTFE expansion bellows contribute to cost savings in power plants? Slash Maintenance and Downtime Costs

- Under what conditions is the coefficient of friction minimized in PTFE slide bearings? Optimize for Low Friction

- What types of PTFE products are available for fluid handling solutions? Your Guide to High-Purity Components

- Why is ePTFE preferred over PTFE in certain applications? Unlock Superior Sealing & Filtration