In high-temperature industries, Teflon (PTFE) sheets are most practically applied in aerospace, automotive manufacturing, and industrial processing. Their value stems from a unique combination of extreme heat resistance, a non-stick surface, and chemical inertness, making them indispensable for protecting equipment, ensuring process integrity, and enhancing safety.

The true value of Teflon sheets in demanding environments is not just their ability to withstand heat. It's how their non-stick and chemically inert properties perform at high temperatures to solve critical challenges related to friction, adhesion, and corrosion.

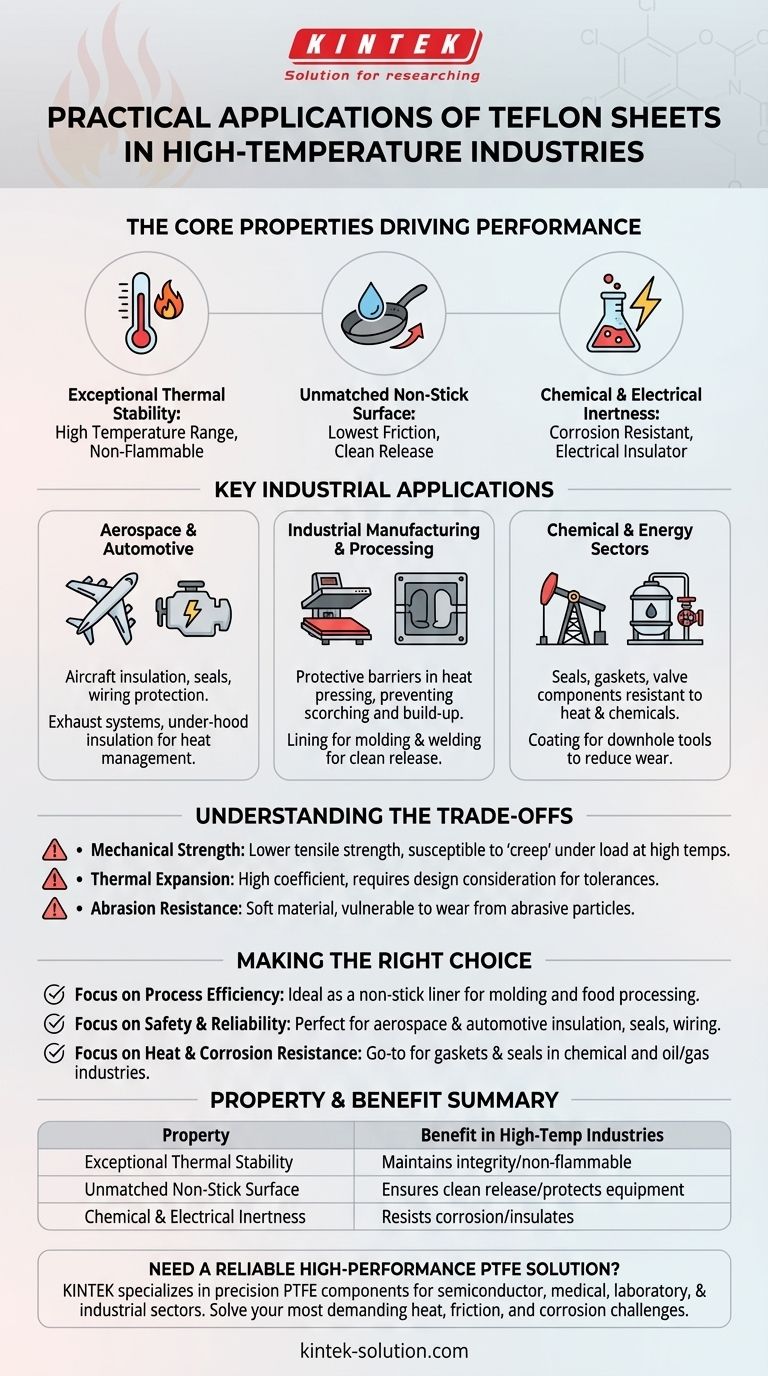

The Core Properties Driving High-Temperature Performance

To understand Teflon's applications, it's essential to understand the properties that make it so effective under thermal stress.

Exceptional Thermal Stability

Teflon, or Polytetrafluoroethylene (PTFE), maintains its structural integrity across a wide temperature range.

This material is also valued for being non-flammable, a critical safety feature in aerospace and enclosed industrial settings.

Unmatched Non-Stick Surface

Teflon has one of the lowest coefficients of friction of any solid material, creating an unparalleled non-stick surface.

This property is crucial in manufacturing processes like molding or heat pressing, as it prevents materials from sticking to equipment, ensuring a clean release and protecting expensive machinery.

Chemical and Electrical Inertness

Teflon is almost completely inert, meaning it resists corrosion and degradation from nearly all industrial chemicals, even at elevated temperatures.

It also serves as an excellent electrical insulator, a property vital for protecting sensitive wiring and electronic components in hot environments like engine bays or industrial ovens.

Key Industrial Applications Breakdown

These core properties translate directly into practical, high-value applications across several key sectors.

Aerospace and Automotive

In aerospace, Teflon sheets are used for aircraft insulation, high-performance seals, and wiring protection. Their heat resistance and non-flammability are critical for safety and reliability.

Similarly, the automotive industry uses them for exhaust system components and under-the-hood insulation to manage intense engine heat and prevent wear.

Industrial Manufacturing and Processing

In heat press applications, a Teflon sheet provides a protective, non-stick barrier. This ensures even heat distribution, prevents scorching, and protects the heat platen from ink or adhesive buildup.

For industrial molding and welding, the sheets act as protective linings or release surfaces, preventing molten materials from adhering to molds and equipment, which enhances efficiency and lifespan.

Chemical and Energy Sectors

The oil and gas industry relies on Teflon for seals, gaskets, and valve components that must withstand both high temperatures and corrosive chemicals.

It's also used to coat downhole tools like drill bits, where its low-friction surface reduces wear and tear in extreme operating conditions.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. Acknowledging its limitations is key to using it properly.

Mechanical Strength

Compared to metals, PTFE has lower tensile strength and is susceptible to "creep"—a slow deformation under sustained load, which can be accelerated by high temperatures.

Thermal Expansion

Teflon has a relatively high coefficient of thermal expansion. Engineers must account for this in designs with tight tolerances to prevent parts from failing as temperatures change.

Abrasion Resistance

While it has a low-friction surface, PTFE is a relatively soft material and can be vulnerable to wear from hard, abrasive particles.

Making the Right Choice for Your Application

Selecting Teflon should be based on the primary challenge you need to solve.

- If your primary focus is process efficiency and protection: Teflon is ideal as a non-stick liner in heat pressing, molding, and food processing to ensure clean release and protect equipment.

- If your primary focus is safety and reliability in extreme heat: Its use in aerospace and automotive insulation, seals, and wiring is a perfect fit due to its thermal stability and non-flammability.

- If your primary focus is resisting both heat and corrosion: Its chemical inertness makes it the go-to choice for gaskets, seals, and linings in chemical processing and the oil and gas industry.

Ultimately, Teflon sheets provide a powerful engineering solution for complex problems where heat, friction, and chemical exposure intersect.

Summary Table:

| Property | Benefit in High-Temp Industries |

|---|---|

| Exceptional Thermal Stability | Maintains integrity and is non-flammable in extreme heat (aerospace, automotive). |

| Unmatched Non-Stick Surface | Ensures clean release, protects equipment in molding and heat pressing. |

| Chemical & Electrical Inertness | Resists corrosion and insulates in harsh chemical and high-temperature environments. |

Need a reliable high-performance PTFE solution?

KINTEK specializes in manufacturing precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine superior material properties with expert custom fabrication, from prototypes to high-volume orders, to solve your most demanding heat, friction, and corrosion challenges.

Contact KINTEK today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What advantages do Graphite packings offer when treated with PTFE? Achieve Superior Sealing Performance

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What is the difference between PTFE sheets and Teflon paper? A Guide to Choosing the Right Form

- What industries commonly use PTFE envelope gaskets? Solve Sealing Challenges in Harsh & Pure Environments

- What are some innovative applications of CNC machined PTFE in product design? Unlock Extreme Performance in Medical, Aerospace & Electronics

- What is Teflon AF and what are its optical properties? Achieve Superior Optical Clarity with UV Resistance

- What are the two primary types of PTFE used in slide bearings and their respective applications? Choose the Right Grade for Your Load and Environment

- What are PTFE compounds and how are they used? Enhance Performance for Demanding Applications