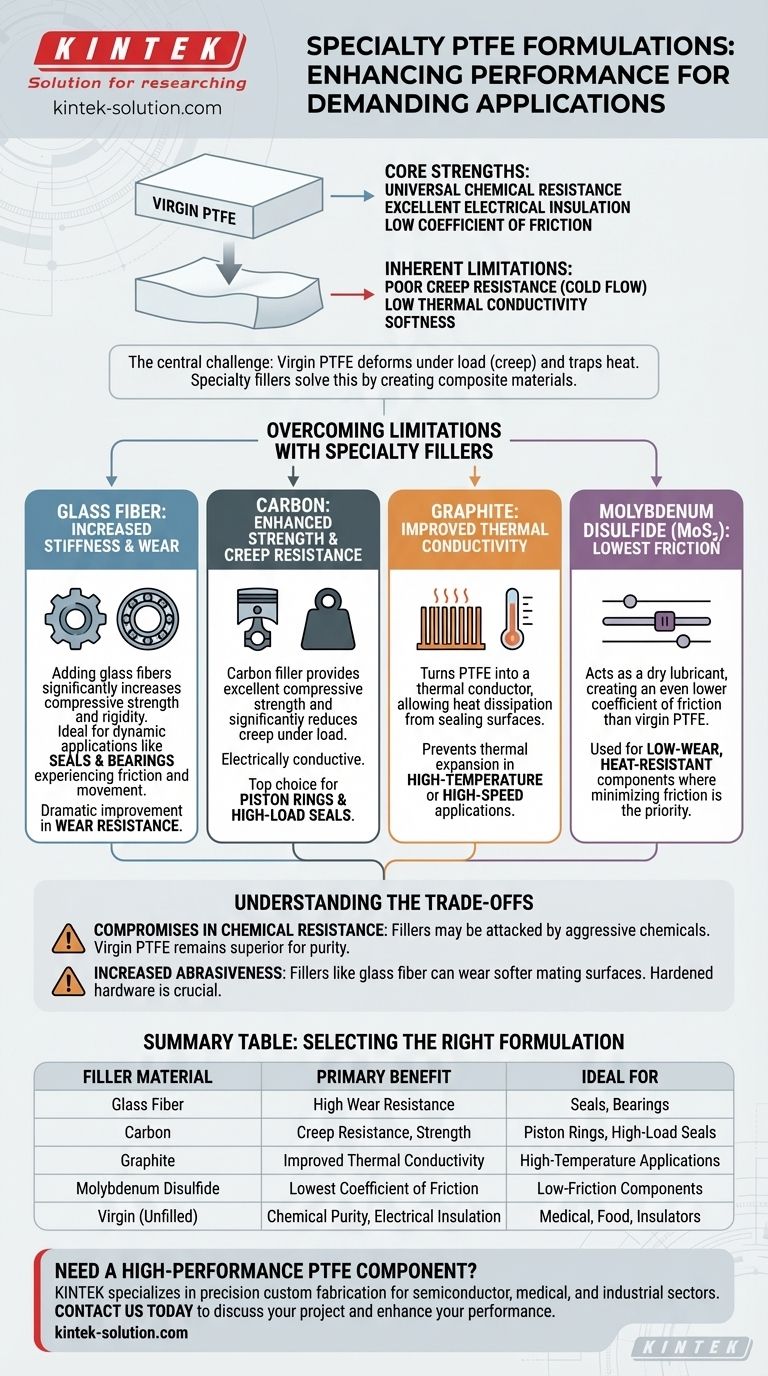

At its core, specialty PTFE formulations are created by adding fillers to standard PTFE to enhance specific mechanical or thermal properties. Common examples include glass fiber-filled PTFE for better wear resistance, carbon-filled PTFE for reduced creep, graphite-filled PTFE for improved thermal conductivity, and molybdenum disulfide-filled PTFE for an even lower coefficient of friction.

The central challenge with standard (virgin) PTFE is its softness and tendency to deform under load, a phenomenon known as "creep." Specialty formulations solve this by embedding reinforcing fillers into the PTFE matrix, creating a composite material tailored to specific engineering demands like wear resistance or heat dissipation.

The Baseline: Understanding Virgin PTFE

Core Strengths

Virgin Polytetrafluoroethylene (PTFE) is a remarkable material known for several key properties. It offers near-universal chemical resistance, excellent electrical insulation, and a very low coefficient of friction.

This makes it an ideal choice for applications requiring purity, such as in the food or medical industries, and for components like basic seals or electrical insulators.

Inherent Limitations

However, virgin PTFE is mechanically soft. Its primary weakness is poor resistance to creep, or cold flow, where the material slowly deforms under sustained pressure.

It also has low thermal conductivity, meaning it traps heat, and only moderate wear resistance, making it unsuitable for high-load dynamic applications.

Overcoming Limitations with Specialty Fillers

To address the mechanical shortcomings of virgin PTFE, specific fillers are added to create enhanced formulations. Each filler targets a different weakness.

For Increased Stiffness and Wear: Glass Fiber

Adding glass fibers is one of the most common ways to enhance PTFE. This significantly increases compressive strength and rigidity.

The primary benefit is a dramatic improvement in wear resistance, making it ideal for seals and bearings that experience movement and friction.

For Enhanced Strength and Creep Resistance: Carbon

Carbon filler provides excellent compressive strength and significantly reduces the tendency of PTFE to creep under load.

This formulation also offers good thermal conductivity and is electrically conductive, unlike virgin or glass-filled PTFE. It is a top choice for piston rings and seals in demanding applications.

For Improved Thermal Conductivity: Graphite

Graphite is added almost exclusively to improve thermal management. It turns PTFE from a thermal insulator into a thermal conductor.

This allows heat to dissipate away from sealing or bearing surfaces, preventing thermal expansion and premature failure in higher-temperature or high-speed applications.

For the Lowest Friction: Molybdenum Disulfide (MoS₂)

While virgin PTFE is already slippery, adding molybdenum disulfide (MoS₂) creates an even lower coefficient of friction.

This filler acts as a dry lubricant, making the material exceptionally slick. It is often used for low-wear, heat-resistant components in applications where minimizing friction is the absolute priority.

Understanding the Trade-offs

Compromises in Chemical Resistance and Purity

Adding any filler means the resulting material is no longer 100% pure PTFE. While generally maintaining excellent chemical resistance, certain aggressive chemicals may attack the filler material itself.

This is a critical consideration for applications in harsh chemical processing environments where the universal compatibility of virgin PTFE is required.

Increased Abrasiveness

Fillers like glass fiber can be abrasive to softer mating surfaces. When designing with glass-filled PTFE, it is crucial to ensure that the hardware it runs against (like a steel shaft) is sufficiently hardened to prevent premature wear.

Selecting the Right Formulation for Your Application

Choosing the correct material requires matching the formulation's strengths to your primary engineering goal.

- If your primary focus is wear resistance and rigidity: Glass fiber-filled PTFE is the most effective and common choice.

- If your primary focus is resisting deformation (creep) under high loads: Carbon-filled PTFE provides the best structural integrity.

- If your primary focus is dissipating heat from a dynamic seal: Graphite-filled PTFE is specifically designed for thermal conductivity.

- If your primary focus is achieving the absolute minimum friction: Molybdenum disulfide-enhanced PTFE offers superior self-lubricating properties.

- If your primary focus is purity, chemical inertness, or electrical insulation: Virgin PTFE remains the superior and often necessary option.

Ultimately, selecting the right PTFE formulation is about targeting the specific weakness of the base material to meet the demands of your application.

Summary Table:

| Filler Material | Primary Benefit | Ideal For |

|---|---|---|

| Glass Fiber | High Wear Resistance | Seals, Bearings |

| Carbon | Creep Resistance, Strength | Piston Rings, High-Load Seals |

| Graphite | Improved Thermal Conductivity | High-Temperature Applications |

| Molybdenum Disulfide | Lowest Coefficient of Friction | Low-Friction Components |

| Virgin (Unfilled) | Chemical Purity, Electrical Insulation | Medical, Food, Insulators |

Need a high-performance PTFE component tailored to your exact requirements?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise in custom fabrication ensures your application gets the right material properties, whether it's wear resistance, creep resistance, or thermal management.

Contact us today to discuss your project and let our solutions enhance your performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry