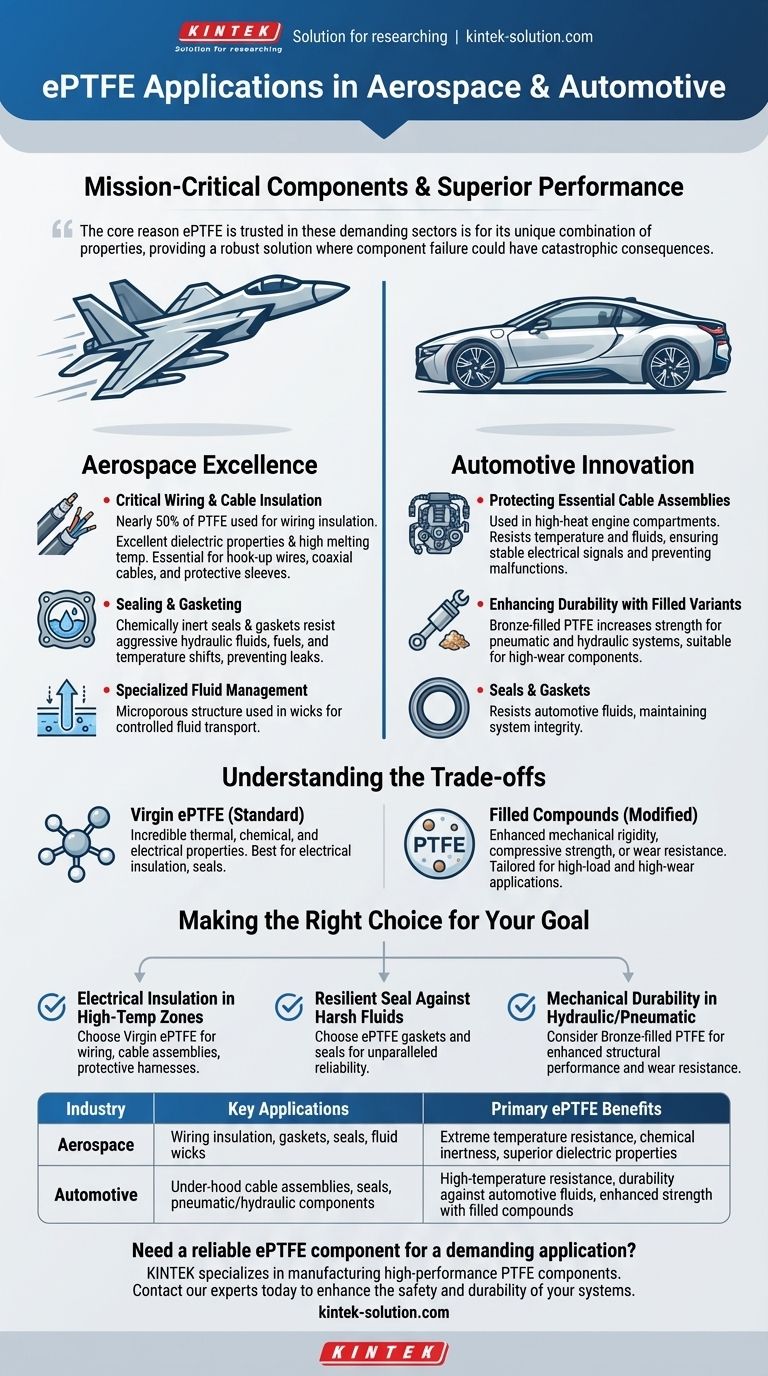

In both aerospace and automotive industries, expanded Polytetrafluoroethylene (ePTFE) is primarily used for mission-critical components like high-performance wiring insulation, protective sleeves, gaskets, and seals. Its selection is driven by its exceptional resistance to extreme temperatures, chemical exposure, and its superior electrical insulation properties, which ensure reliability in harsh operating environments.

The core reason ePTFE is trusted in these demanding sectors is not just for one single attribute, but for its unique combination of properties. It provides a robust solution where component failure could have catastrophic consequences, ensuring both safety and long-term operational integrity.

Why ePTFE Excels in Aerospace

The aerospace environment is defined by extreme temperature fluctuations, high vibration, and the absolute need for reliability. ePTFE's material properties make it an ideal candidate to solve these challenges.

Critical Wiring and Cable Insulation

A significant portion of all PTFE produced—nearly 50%—is used for wiring insulation in aerospace and computer applications.

It serves as a high-performance substitute for materials like polyethylene due to its excellent dielectric properties and a very high melting temperature, which prevents failure in high-heat zones.

This makes it essential for hook-up wires, coaxial cables, and the protective wire harness sleeves that bundle and shield critical electrical systems throughout an aircraft.

Sealing and Gasketing in Harsh Environments

Aircraft systems are exposed to aggressive hydraulic fluids, fuels, and dramatic temperature shifts.

ePTFE is fabricated into gaskets and seals because it is chemically inert and maintains its integrity across a wide temperature range, preventing leaks and system contamination.

Specialized Fluid Management

The unique microporous structure of ePTFE allows it to be used in specialized components like wicks. These are used to transport fluids in a controlled manner, leveraging the material's inertness and structural properties.

How the Automotive Industry Leverages ePTFE

While the automotive environment is less extreme than aerospace, the push for higher performance, efficiency, and durability creates similar material demands, especially under the hood.

Protecting Essential Cable Assemblies

ePTFE is frequently used in cable assemblies within the engine compartment and other high-heat areas of a vehicle.

Its resistance to high temperatures and automotive fluids ensures that electrical signals remain stable and protected, preventing system malfunctions over the vehicle's lifespan.

Enhancing Durability with Filled Variants

For applications requiring greater mechanical strength, such as in pneumatic and hydraulic systems, modified versions of the material are used.

Bronze-filled PTFE, for example, significantly increases the material's strength and durability, making it suitable for high-wear components where standard ePTFE might not suffice.

Understanding the Trade-offs

While ePTFE offers exceptional performance, it is important to understand its context and limitations to make an informed decision. It is a specialized material, not a universal solution.

Virgin ePTFE vs. Filled Compounds

Standard, or "virgin," ePTFE has incredible thermal, chemical, and electrical properties but may lack the mechanical rigidity for high-load applications.

This is precisely why filled compounds exist. By adding materials like bronze, glass, or carbon, engineers can enhance specific properties like compressive strength or wear resistance, tailoring the material to the application.

A Targeted, High-Performance Material

ePTFE is a premium material chosen for roles where more common polymers like polyethylene would degrade and fail.

Its value is realized in applications where its specific strengths—especially thermal stability and chemical inertness—are mandatory for safety and reliability.

Making the Right Choice for Your Goal

Your specific objective will determine whether ePTFE is the appropriate choice and in what form.

- If your primary focus is electrical insulation in high-temperature zones: Virgin ePTFE is the ideal choice for wiring, cable assemblies, and protective harnesses.

- If your primary focus is creating a resilient seal against harsh fluids: ePTFE gaskets and seals offer unparalleled reliability and longevity.

- If your primary focus is mechanical durability in a hydraulic or pneumatic system: Consider a bronze-filled PTFE compound to enhance structural performance and wear resistance.

Ultimately, selecting ePTFE is a strategic decision for applications where operational integrity and long-term reliability are paramount.

Summary Table:

| Industry | Key Applications | Primary ePTFE Benefits |

|---|---|---|

| Aerospace | Wiring insulation, gaskets, seals, fluid wicks | Extreme temperature resistance, chemical inertness, superior dielectric properties |

| Automotive | Under-hood cable assemblies, seals, pneumatic/hydraulic components | High-temperature resistance, durability against automotive fluids, enhanced strength with filled compounds |

Need a reliable ePTFE component for a demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring precision and reliability from prototype to high-volume production.

Contact our experts today to discuss how our ePTFE solutions can enhance the safety and durability of your aerospace or automotive systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts