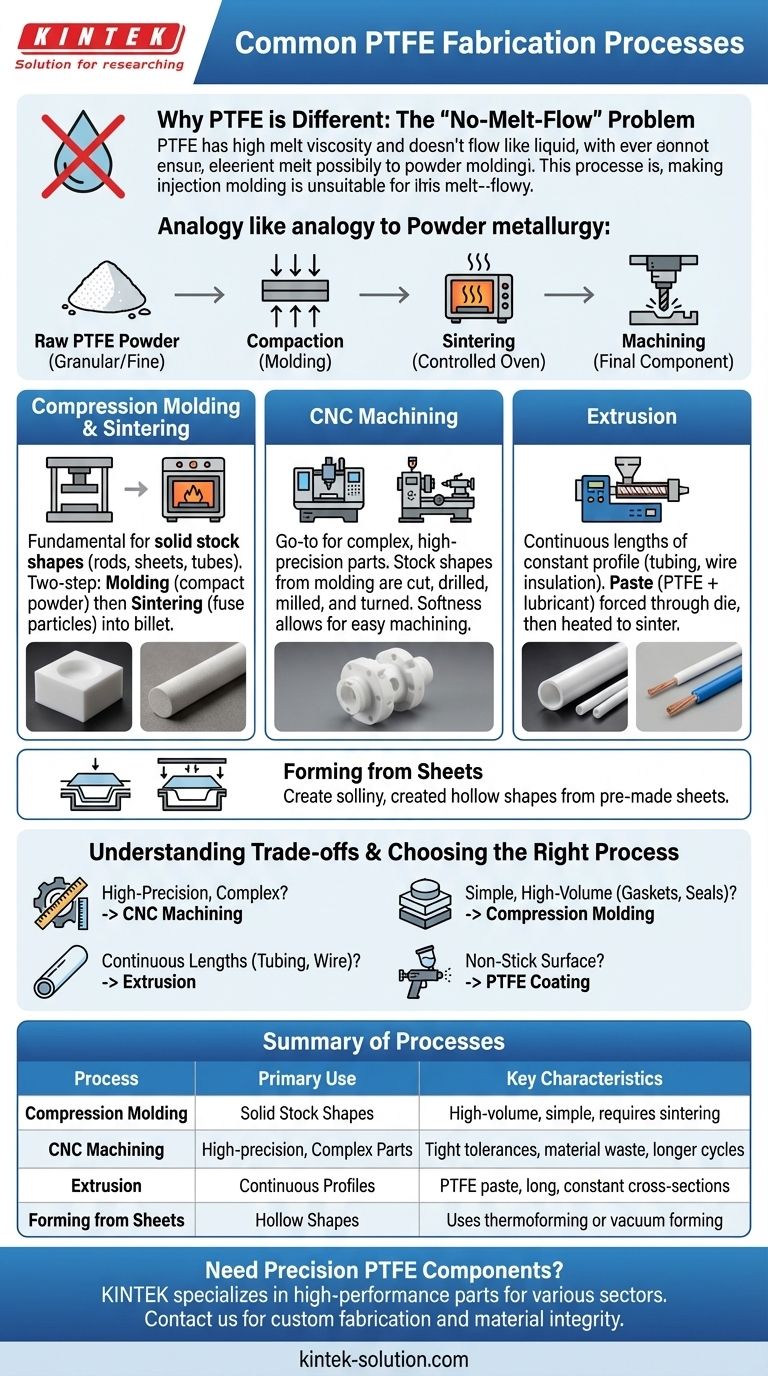

The most common fabrication processes for PTFE are compression molding, CNC machining, and extrusion. Unlike typical plastics, PTFE does not melt into a liquid state, which means it cannot be processed using conventional methods like injection molding. Instead, its fabrication relies on a unique set of techniques tailored to its distinct chemical properties.

The core principle to understand is that PTFE fabrication is more analogous to powder metallurgy than traditional plastics processing. Raw PTFE powder is first compacted into a solid form under pressure (molding) and then heated in a controlled oven to fuse the particles (sintering) before it can be machined into a final, precise component.

Why PTFE Fabrication is Different

To select the right process, it's essential to first understand why PTFE requires special handling. Its unique molecular structure is the root cause.

The "No-Melt-Flow" Problem

PTFE has an extremely high melt viscosity, meaning even when heated past its melting point, it doesn't flow like a liquid. It becomes a translucent, gel-like substance.

This property makes conventional melt-processing techniques like injection molding or blow molding completely unsuitable for virgin PTFE.

From Polymerization to Raw Material

Fabrication starts with the raw PTFE resin, which is produced in two primary forms:

- Granular/Suspension PTFE: These are larger grains produced via suspension polymerization. This form is ideal for molding processes to create solid stock shapes like rods, sheets, and tubes.

- Fine Powder/Dispersion PTFE: This milky paste or fine powder is produced via dispersion polymerization and is primarily used for creating coatings or being processed into a paste for extrusion.

Core Fabrication Processes Explained

The form of the raw material directly influences the fabrication method used to create a finished part.

Compression Molding & Sintering

This is the most fundamental process for creating solid PTFE components. It’s a two-step method:

- Molding: Granular PTFE powder is loaded into a mold and compacted under high pressure to form a preform shape, often called a billet.

- Sintering: The preform is removed from the mold and heated in a highly controlled oven to a temperature above its melting point. The PTFE particles fuse together, creating a solid, dense block.

This process is used to create the stock shapes (rods, tubes, sheets) that are often the starting point for a finished part.

CNC Machining

Because molding produces relatively simple shapes, CNC machining is the go-to method for creating complex, high-precision parts.

Stock shapes from the molding process are loaded into CNC mills or lathes. The material is then cut, drilled, milled, or turned into the final component. PTFE is easily machined with standard tooling due to its softness.

Extrusion

Extrusion is used to create continuous lengths of a constant profile, such as tubing, wire insulation, or thin films.

A paste made from fine PTFE powder and a lubricant is forced through a die to create the desired shape. The extruded part is then heated to remove the lubricant and sinter the PTFE.

Forming from Sheets

For certain applications, pre-made PTFE sheets can be shaped using heat and pressure.

Methods like thermoforming (heating and molding) and vacuum forming (using vacuum pressure) can be used to create specific, often hollow, shapes from a sintered sheet.

Understanding the Trade-offs

Each process comes with its own set of advantages and limitations that are critical for making an informed decision.

Molding: Ideal for Volume, Not for Complexity

Compression molding is highly efficient for producing simple, standard stock shapes in large volumes. However, it cannot create intricate geometries or features like threads and sharp internal corners.

Machining: Precision at a Cost

CNC machining delivers exceptional precision and can produce highly complex parts with tight tolerances. The primary trade-off is cost, as it involves material waste (chips) and longer cycle times compared to molding.

Sintering: The Critical Control Point

The final mechanical and physical properties of a PTFE part are heavily dependent on the sintering cycle. Improper control of temperature, time, and cooling rates can result in a part with poor performance characteristics, even if it looks correct.

Choosing the Right Process for Your Application

Selecting the correct fabrication path depends entirely on the requirements of your final part.

- If your primary focus is high-precision, complex parts: Your part will almost certainly be CNC machined from a pre-molded and sintered stock shape (rod, billet, or tube).

- If your primary focus is producing simple, high-volume shapes (like gaskets or seals): Direct compression molding and sintering of the final shape may be the most cost-effective solution.

- If your primary focus is creating continuous lengths (like tubing or wire insulation): Extrusion is the only viable process for these applications.

- If your primary focus is applying a non-stick surface to another material: You are looking for a PTFE coating, which uses the fine powder form in a spray and bake process.

Understanding these distinct fabrication pathways is the key to successfully leveraging the exceptional properties of PTFE for your project.

Summary Table:

| Process | Primary Use | Key Characteristics |

|---|---|---|

| Compression Molding | Creating solid stock shapes (rods, sheets, tubes) | High-volume production, simple shapes, requires sintering |

| CNC Machining | High-precision, complex parts | Excellent for tight tolerances, material waste, longer cycle times |

| Extrusion | Continuous profiles (tubing, wire insulation) | Uses PTFE paste, ideal for long, constant cross-sections |

| Forming from Sheets | Hollow shapes from pre-made sheets | Uses thermoforming or vacuum forming techniques |

Need Precision PTFE Components for Your Industry?

KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in compression molding, CNC machining, and extrusion ensures your parts meet the strictest tolerances and performance requirements.

Whether you need prototypes or high-volume production, we deliver:

- Custom fabrication tailored to your exact specifications

- Material integrity through controlled sintering processes

- Cost-effective solutions for both simple and complex geometries

Contact us today to discuss your PTFE project and leverage our specialized fabrication expertise!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are common industrial applications of machined Teflon parts? Solve Friction, Chemical & Electrical Challenges

- What is PV value and why is it important for PTFE seals? Prevent Premature Seal Failure

- How do Medical Grade PTFE Liners exhibit chemical resistance? Unmatched Inertness for Medical Devices

- What are the applications of Teflon bearings in extreme environments? Ensure Reliability from -400°F to +550°F

- What are some common applications of filled PTFE? Enhance Performance in Demanding Industries

- What type of gasket is particularly suitable for industries dealing with hazardous chemicals? The Definitive Choice for Safety

- What are the disadvantages of Teflon encapsulated O-rings? Key Weaknesses and Safer Alternatives

- Why might ink appear on a Teflon sheet during pressing? Prevent Contamination & Ghosting