The most common fillers used to enhance Polytetrafluoroethylene (PTFE) for valve seats are glass fiber, carbon, graphite, bronze, and molybdenum disulfide. These additives are not chosen randomly; they are engineered solutions to overcome the inherent softness and tendency of pure PTFE to deform under pressure. By integrating these materials, a standard polymer is transformed into a high-performance sealing component with superior strength, dimensional stability, and wear resistance.

Pure, or "virgin," PTFE is often too soft and prone to deformation (creep) for demanding valve applications. Adding fillers is a strategic engineering trade-off, sacrificing a small amount of PTFE's legendary low friction to gain critical improvements in mechanical strength and long-term sealing integrity.

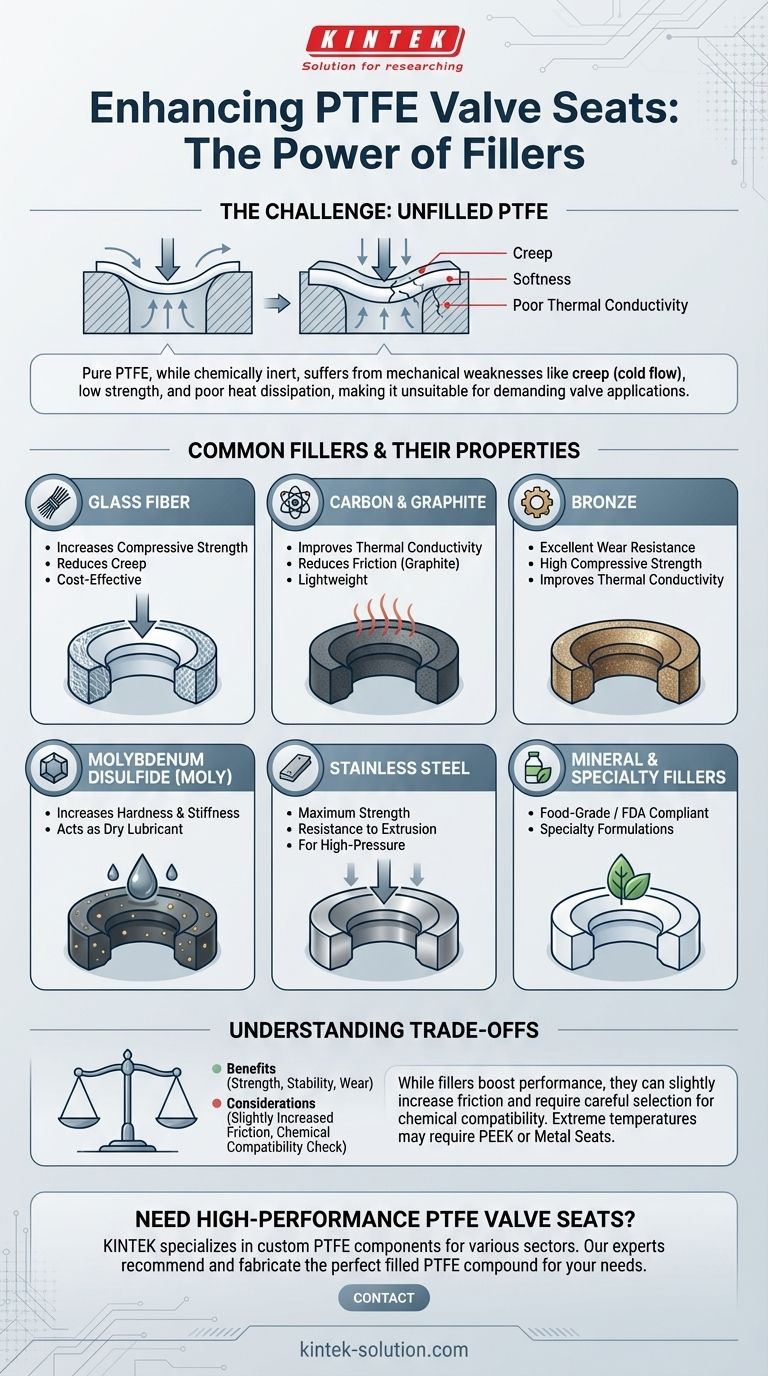

The Challenge with Unfilled PTFE

Unfilled PTFE, while chemically inert and possessing an extremely low coefficient of friction, has significant mechanical limitations. Understanding these weaknesses is key to appreciating the role of fillers.

High Creep and Cold Flow

Under sustained pressure, especially at elevated temperatures, pure PTFE will slowly deform or "flow" out of its intended shape. For a valve seat, this phenomenon, known as creep, can lead to leakage and eventual seal failure.

Limited Mechanical Strength

Pure PTFE is a relatively soft material. It has poor resistance to wear and abrasion, making it unsuitable for applications involving frequent cycling or abrasive media.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed or high-pressure valve applications, friction can generate heat that the PTFE seat cannot effectively dissipate, which can accelerate creep and degradation.

A Guide to Common PTFE Fillers and Their Properties

Each filler imparts a unique set of characteristics to the base PTFE, allowing for tailored performance based on the specific demands of the valve's service environment.

Glass Fiber

Glass fiber is one of the most common and cost-effective fillers. Its primary function is to dramatically increase compressive strength and reduce creep. It provides a rigid internal structure that helps the PTFE seat maintain its shape under load.

Carbon and Graphite

These two fillers are often used to enhance thermal properties and hardness. Carbon provides good mechanical strength and is lighter than other fillers, while graphite significantly improves thermal conductivity and further reduces the coefficient of friction, making it ideal for high-speed or dry-running applications.

Bronze

Adding bronze powder to PTFE results in a composite material with excellent wear resistance and high compressive strength. Bronze also significantly improves thermal conductivity, helping to manage heat generated at the sealing surface.

Molybdenum Disulfide (Moly)

Often used in conjunction with other fillers, molybdenum disulfide (Moly) increases the hardness, stiffness, and wear resistance of the PTFE composite. It acts as a dry lubricant, contributing to a lower coefficient of friction.

Stainless Steel

For high-pressure applications, stainless steel powder is added to provide maximum strength and resistance to extrusion. This filler creates an exceptionally robust material that can withstand forces that would push softer seats out of place.

Mineral and Specialty Fillers

For specific industries, other fillers are used. Mineral fillers, for instance, can be formulated to create food-grade or FDA-compliant PTFE compounds. High-performance polymers like aromatic polyester can also be used as fillers to boost performance at very high temperatures.

Understanding the Trade-offs

While fillers provide clear benefits, they also introduce important considerations that must be balanced to achieve the desired outcome.

A Slight Increase in Friction

Fillers can slightly increase the coefficient of friction compared to virgin PTFE. However, this is a minor trade-off for the crucial gains in mechanical stability and wear life, which ensures the valve's long-term performance.

Chemical Compatibility

The selected filler must be compatible with the media flowing through the valve. For example, while glass fiber is a common choice, it can be attacked by certain aggressive chemicals, making a carbon or bronze-filled variant a better option for that service.

Beyond Filled PTFE

It is critical to recognize the limits of even high-performance filled PTFE. For service temperatures consistently above 280°C (536°F), other materials like PEEK (Polyether-etherketone) or entirely different metal-seated valve designs become necessary.

Selecting the Right Filler for Your Application

The choice of filler should be driven by the primary challenge the valve seat will face in service.

- If your primary focus is general-purpose durability and creep resistance: Glass-filled PTFE is a balanced, common, and effective choice.

- If your primary focus is high pressure and extrusion resistance: Stainless steel-filled PTFE provides the necessary structural strength to prevent seal failure.

- If your primary focus is thermal conductivity for high-speed service: Carbon or graphite-filled PTFE is the superior option for managing heat.

- If your primary focus is food-grade or FDA compliance: A specially formulated mineral-filled PTFE is required to meet regulatory standards.

Ultimately, choosing the right filler transforms PTFE from a simple polymer into a precisely engineered material designed to solve a specific sealing challenge.

Summary Table:

| Filler Material | Key Benefits | Ideal For |

|---|---|---|

| Glass Fiber | Increases compressive strength, reduces creep | General-purpose durability & cost-effectiveness |

| Carbon/Graphite | Improves thermal conductivity, reduces friction | High-speed or dry-running applications |

| Bronze | Enhances wear resistance & thermal conductivity | High-load, high-wear environments |

| Stainless Steel | Maximizes strength & extrusion resistance | High-pressure applications |

| Molybdenum Disulfide | Increases hardness & wear resistance | Applications requiring dry lubrication |

| Mineral Fillers | Provides food-grade/FDA compliance | Food, pharmaceutical, and regulated industries |

Need a high-performance PTFE valve seat tailored to your specific application?

At KINTEK, we specialize in precision manufacturing of custom PTFE components, including seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in material science allows us to recommend and fabricate the perfect filled PTFE compound—whether you need prototypes or high-volume orders—to ensure optimal sealing, longevity, and reliability.

Contact us today to discuss your valve seat requirements and let our engineers deliver a solution that exceeds your expectations!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Is PTFE sheet suitable for food applications? Ensuring FDA-Compliant Safety in Food Processing

- Why are PTFE guide strips suitable for the food and beverage industry? Ensure Safety, Compliance, and Reliability

- What are the main benefits of using PTFE envelope gaskets? Achieve Superior Sealing in Harsh Environments

- How can tight tolerances be achieved in CNC-machined PTFE parts? Master Precision Machining for Stable Components

- What properties make PTFE energized seals suitable for cryogenic applications? Reliable Sealing at Ultra-Low Temperatures

- Why is PTFE used for thermal and electrical insulation? Unmatched Stability in Extreme Conditions

- How does the melting point and thermal stability of PTFE impact its CNC machining? Mastering Heat Control for Precision

- What industries are spiral PTFE backup rings ideal for? Achieve Superior Sealing in Extreme Conditions