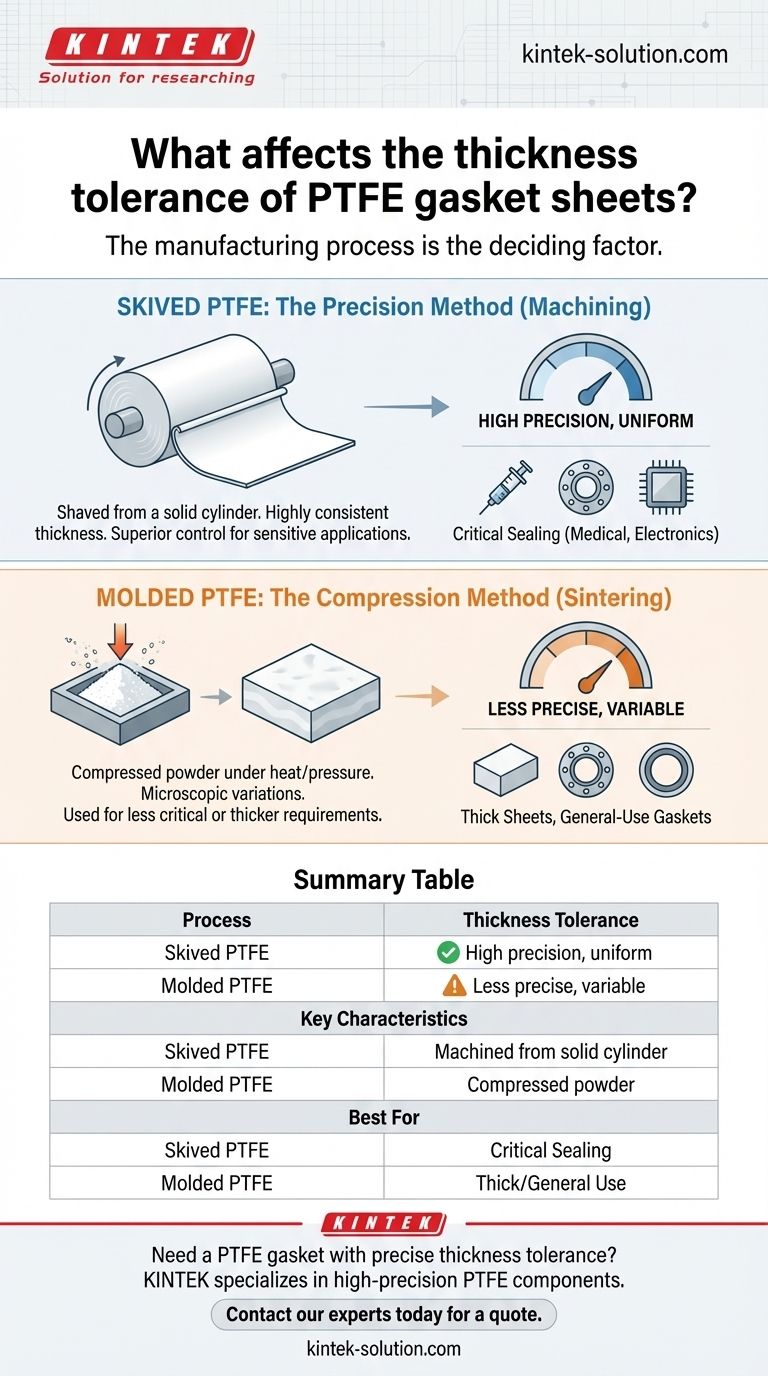

The thickness tolerance of a PTFE gasket sheet is almost entirely determined by its manufacturing process. The two primary methods, skiving and molding, produce sheets with distinctly different levels of consistency, making the choice of process the single most important factor for achieving a desired tolerance.

The core issue is a trade-off between precision and application. Skived PTFE offers superior thickness control suitable for sensitive sealing applications, while molded PTFE is used for less critical or thicker requirements.

Manufacturing's Decisive Role in Tolerance

To understand why thickness varies, you must first understand how the sheets are made. The physical process used to form the sheet sets the boundaries for how precise the final product can be.

Skived PTFE: The Precision Method

Skiving is a machining process. It involves shaving or peeling a continuous, thin film from a large, solid cylinder of sintered PTFE.

This method is analogous to a veneer slicer cutting a thin layer of wood from a log. Because it relies on a controlled, mechanical cutting action, skiving produces sheets with a highly consistent and uniform thickness across their entire surface.

Molded PTFE: The Compression Method

Molding involves compressing PTFE powder into a specific shape (like a block or sheet) under high pressure and heat, a process called sintering.

While effective, this compression method can introduce microscopic variations in density and material flow within the mold. This results in a final sheet with a less precise thickness tolerance compared to a skived sheet.

Understanding the Practical Trade-offs

Choosing a manufacturing method isn't just about tolerance. The right choice depends on balancing the need for precision with other design constraints like thickness and cost.

When Precision is Paramount

For critical sealing applications in flanges, electronics, or medical devices, a consistent gasket thickness is non-negotiable. An uneven gasket can lead to inconsistent sealing pressure and eventual leak paths.

In these scenarios, the superior tolerance of skived PTFE is the only reliable choice.

When Thickness is the Priority

The skiving process is inherently limited to producing thinner sheets. If your application requires a very thick PTFE block or plate, it was almost certainly produced through molding.

Molding is the standard method for creating billets, rods, and thick sheets that are often machined into final parts later. Here, the initial thickness tolerance is less critical than the bulk material properties.

How to Specify for Your Goal

Selecting the right material requires aligning your application's needs with the capabilities of the manufacturing process.

- If your primary focus is reliable sealing and tight tolerance: You must specify skived PTFE sheets to ensure consistent thickness and performance.

- If your primary focus is creating a thick part or a general-use gasket: A molded PTFE sheet is often sufficient and may be the only option for significant thicknesses.

By understanding how the material is made, you can confidently specify the exact PTFE sheet your design requires.

Summary Table:

| Manufacturing Process | Thickness Tolerance | Key Characteristics | Best For |

|---|---|---|---|

| Skived PTFE | High precision, uniform | Machined from a solid cylinder | Critical sealing applications (flanges, medical devices, electronics) |

| Molded PTFE | Less precise, variable | Compressed PTFE powder under heat/pressure | Thick sheets, blocks, general-use gaskets |

Need a PTFE gasket with precise thickness tolerance for your critical application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gaskets, seals, and liners. Whether your project in the semiconductor, medical, or laboratory industry requires the superior consistency of skived PTFE or the bulk properties of molded PTFE, we deliver the exact specifications you need.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to ensure a perfect seal and reliable performance.

Contact our experts today to discuss your PTFE gasket requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications