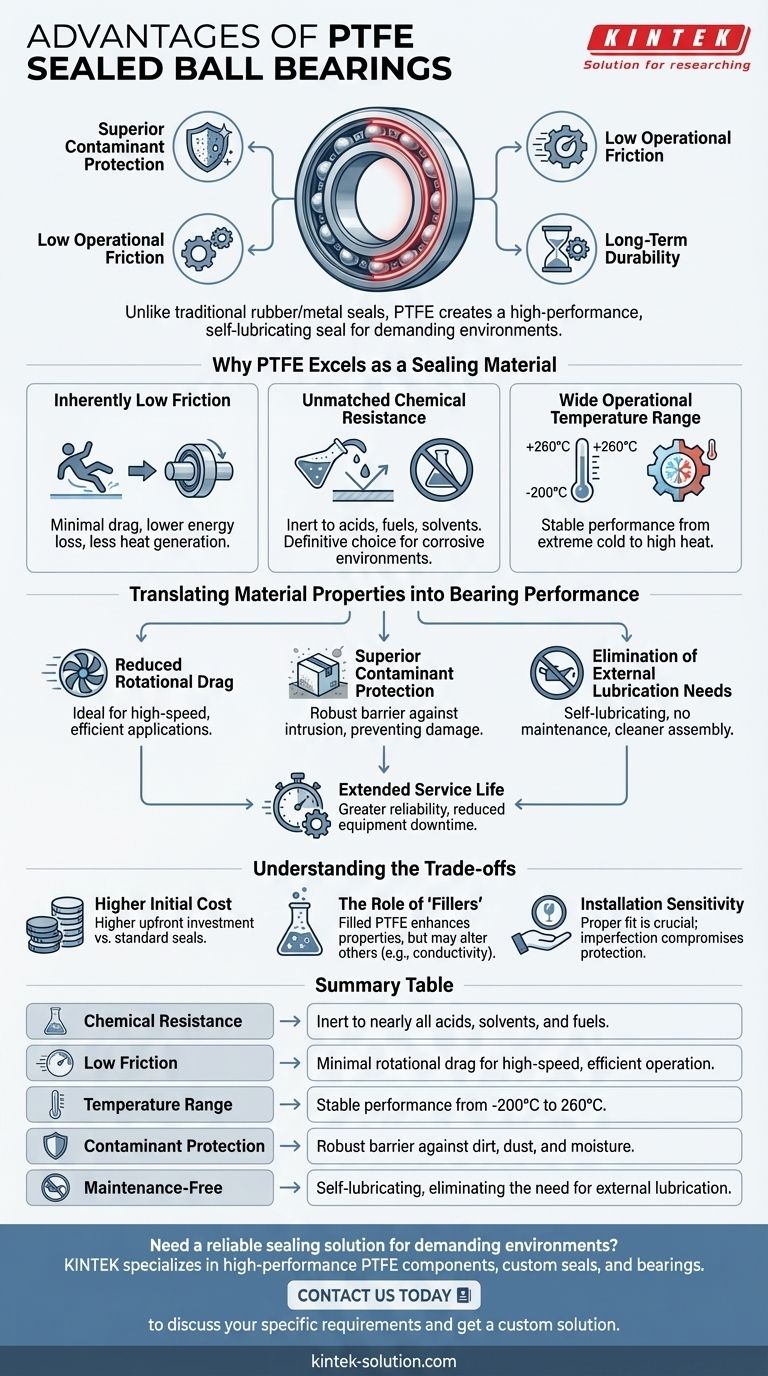

At their core, PTFE sealed ball bearings provide a superior combination of contaminant protection, low operational friction, and long-term durability. Unlike traditional rubber or metal seals, the unique properties of Polytetrafluoroethylene (PTFE) create a high-performance seal that excels in demanding environments without requiring external lubrication.

The primary advantage of PTFE sealed bearings is not a single feature, but how the material's inherent properties—chemical inertness and low friction—create a self-lubricating, highly protective system that extends bearing life and maintains performance where other seal types would fail.

Why PTFE Excels as a Sealing Material

The benefits of a PTFE sealed bearing are a direct result of the fundamental properties of the material itself. Understanding these properties is key to appreciating its advantages in application.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any known solid. This "slipperiness" is a core advantage.

It means the seal creates minimal drag against the rotating inner race of the bearing. This translates directly to lower energy loss and less heat generation during operation.

Unmatched Chemical Resistance

PTFE is chemically inert, meaning it is non-reactive to nearly all industrial chemicals, acids, fuels, and solvents.

This makes PTFE seals the definitive choice for applications in corrosive environments where a standard rubber seal would quickly degrade and fail, leading to bearing contamination.

Wide Operational Temperature Range

The material maintains its integrity across a vast temperature spectrum, from cryogenic conditions (-200°C) up to approximately 260°C (500°F).

This stability ensures the seal remains effective and does not become brittle or lose its shape in applications involving extreme temperature fluctuations.

Translating Material Properties into Bearing Performance

These material characteristics deliver tangible advantages in the real-world performance and longevity of the ball bearing.

Superior Contaminant Protection

The seal provides a robust physical barrier against dirt, dust, and moisture.

Because the material is non-porous and chemically resistant, it prevents intrusion from aggressive liquids and fine particulates that could damage the bearing's internal raceways and balls.

Reduced Rotational Drag

Compared to a standard contact seal made of rubber, a PTFE seal imparts significantly less friction on the rotating components.

This allows the bearing to spin more freely, making it ideal for high-speed applications or situations where every bit of efficiency counts.

Elimination of External Lubrication Needs

PTFE's self-lubricating nature means the seal itself requires no maintenance.

This characteristic also prevents the common problem of dirt and debris clinging to external grease, keeping the entire bearing assembly cleaner and reducing wear over time.

Extended Service Life

The combination of excellent protection, low wear, and chemical stability means PTFE sealed bearings last longer.

By preventing the primary causes of bearing failure—contamination and lubricant breakdown—these seals ensure greater reliability and reduce costly equipment downtime.

Understanding the Trade-offs

While highly effective, it's important to approach the selection of PTFE seals with a full understanding of their context.

Higher Initial Cost

Bearings equipped with high-performance PTFE seals typically have a higher upfront cost compared to those with standard rubber or metal shields.

This cost must be weighed against the long-term benefits of reduced maintenance, lower risk of failure, and extended lifespan.

The Role of "Fillers"

Pure PTFE can be relatively soft. To enhance properties like wear resistance or thermal conductivity, manufacturers often use "filled PTFE," which includes additives like glass, carbon, or graphite.

While these fillers improve mechanical strength, they can alter other properties. For example, carbon-filled PTFE is more conductive and may not be suitable for applications requiring high electrical insulation.

Installation Sensitivity

A seal's performance is highly dependent on a proper fit and installation.

Care must be taken not to nick or damage the PTFE seal during the bearing installation process, as even a small imperfection can compromise its protective capabilities.

Making the Right Choice for Your Application

Selecting the correct bearing seal depends entirely on the operational demands of your specific goal.

- If your primary focus is maximum speed and low drag: PTFE seals offer minimal friction compared to traditional contact seals, maximizing rotational efficiency.

- If your primary focus is operating in corrosive or wet environments: PTFE's unparalleled chemical inertness provides the most reliable protection for the bearing's internal components.

- If your primary focus is minimizing maintenance and maximizing lifespan: The self-lubricating, durable, and highly protective nature of PTFE creates a robust, long-lasting solution.

Ultimately, choosing a PTFE sealed bearing is an investment in reliability and performance for applications where standard solutions are inadequate.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Resistance | Inert to nearly all acids, solvents, and fuels. |

| Low Friction | Minimal rotational drag for high-speed, efficient operation. |

| Temperature Range | Stable performance from -200°C to 260°C. |

| Contaminant Protection | Robust barrier against dirt, dust, and moisture. |

| Maintenance-Free | Self-lubricating, eliminating the need for external lubrication. |

Need a reliable sealing solution for demanding environments?

KINTEK specializes in manufacturing high-performance PTFE components, including custom seals and bearings, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates with maximum efficiency and longevity.

Contact us today to discuss your specific requirements and get a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise during the manufacturing of skived PTFE sheets? Achieving Consistent Quality and Performance

- Which type of PTFE gasket is better for uneven surfaces or fragile flanges? Seal with Confidence Using ePTFE

- What are the available forms of PTFE semi-finished products? A Guide to Stock Shapes for Machining

- What are the disadvantages of PTFE lined butterfly valves? Understanding Key Operational Limits

- How to choose the right PTFE lined butterfly valve? A Guide for Maximum Chemical Resistance & Reliability

- What are the torque requirements for PTFE gaskets according to EN 1591-1? A Guide to Reliable Sealing

- What are the key considerations for PTFE lined butterfly valve installation? Protect Your Liner for a Leak-Proof Seal

- What is the significance of biocompatibility in PTFE fasteners for medical devices? Ensure Patient Safety and Device Reliability