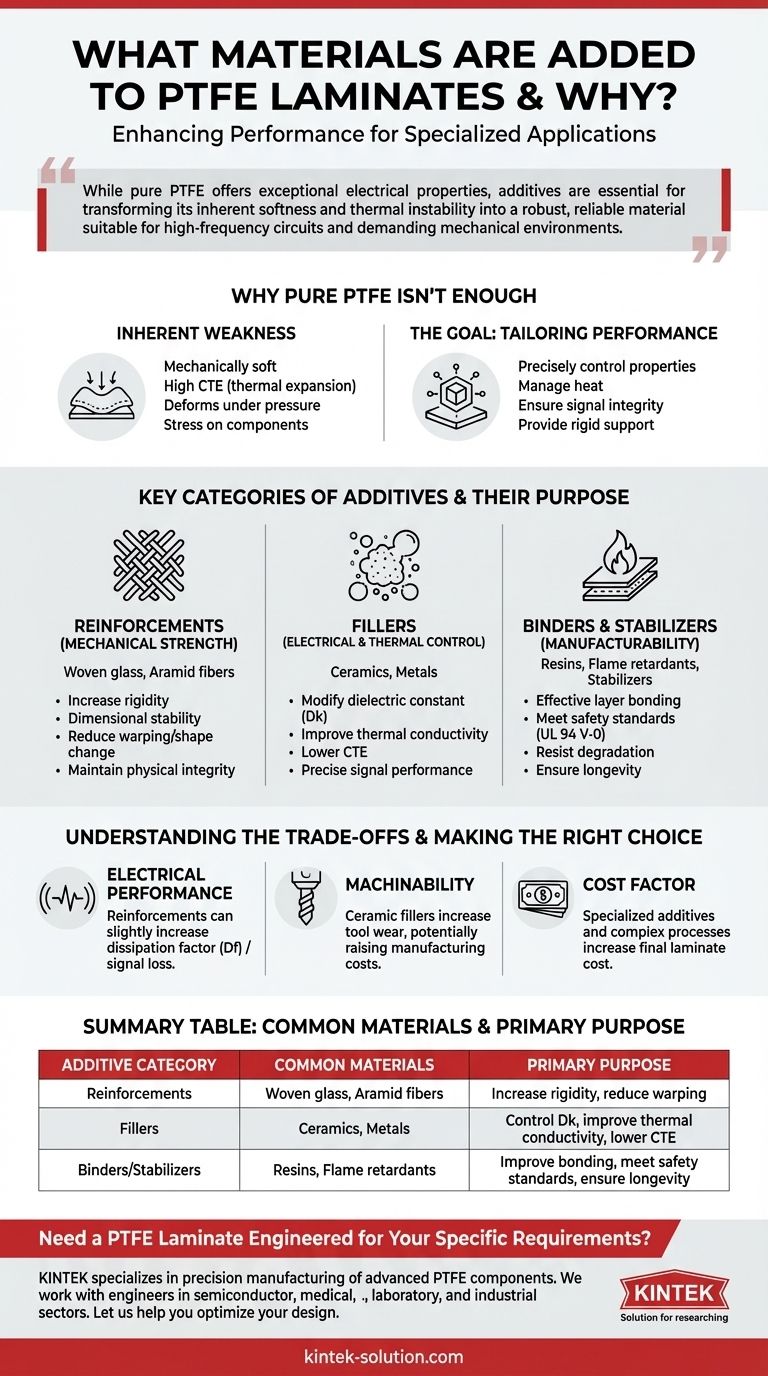

To enhance its performance for specialized applications, PTFE laminate materials are almost always combined with other materials. The most common additives are reinforcements like glass fiber, functional fillers like ceramics, and chemical agents such as resins, flame retardants, and stabilizers. These additions are not optional; they are critical for improving the material's mechanical strength, thermal conductivity, and electrical properties to meet the demands of high-performance electronics and industrial components.

While pure PTFE offers exceptional electrical properties and chemical resistance, it is rarely used alone in laminates. Additives are essential for transforming PTFE's inherent softness and thermal instability into a robust, reliable material suitable for high-frequency circuits and demanding mechanical environments.

Why Pure PTFE Isn't Enough

Pure PTFE is an excellent insulator with a very low coefficient of friction, but it has significant limitations for use in structural laminates like printed circuit boards (PCBs). Additives are used to overcome these specific weaknesses.

The Inherent Weakness of PTFE

Pure PTFE is mechanically soft and has a high coefficient of thermal expansion (CTE). This means it can deform under pressure and will expand and contract significantly with temperature changes, causing stress on attached components like copper traces and solder joints.

The Goal: Tailoring Performance

By adding specific materials to the PTFE matrix, manufacturers can precisely control the final properties of the laminate. This allows engineers to choose a material tailored for specific challenges, whether it's managing heat, ensuring signal integrity at microwave frequencies, or providing rigid support.

Key Categories of Additives and Their Purpose

The additives used in PTFE laminates can be grouped by the primary function they serve: improving mechanical, thermal, or electrical properties, or aiding in the manufacturing process itself.

Reinforcements for Mechanical Strength

The primary goal of reinforcement is to add rigidity and dimensional stability.

Woven glass or aramid fibers are the most common reinforcements. They create a strong internal structure within the PTFE, drastically reducing its tendency to warp or change shape with temperature fluctuations. This is critical for maintaining the physical integrity of a PCB.

Fillers for Electrical and Thermal Control

Fillers are typically micro-particles mixed into the PTFE matrix to fine-tune its performance characteristics.

Ceramic fillers are widely used to modify the laminate's electrical and thermal properties. They help to lower the CTE and, most importantly, allow for precise control over the material's dielectric constant (Dk), which is crucial for high-frequency signal performance. They also improve thermal conductivity, helping to dissipate heat from active components.

Metal fillers can also be used in applications where maximizing thermal conductivity is the primary goal.

Binders and Stabilizers for Manufacturability

This category of additives ensures the material can be reliably manufactured and will last in the field.

Resins are often added to help the PTFE and filler materials bond more effectively to each other and to other layers in a multi-layer board stackup, such as copper foil.

Flame retardants and stabilizers are included to ensure the material can meet industry safety standards for flammability (like UL 94 V-0) and to resist degradation from aging, heat, and chemical exposure over its operational lifetime.

Understanding the Trade-offs

Adding materials to the PTFE matrix is a balancing act. Improving one property can sometimes negatively impact another, and it is crucial to understand these compromises.

The Impact on Electrical Performance

While reinforcements like glass fiber add immense strength, their dielectric properties are different from pure PTFE. This can slightly increase the dissipation factor (Df), or signal loss, of the material. The design of the glass weave itself can impact signal integrity.

The Effect on Machinability

Adding hard ceramic fillers makes the laminate much more stable and thermally conductive, but it also makes the material more abrasive. This can increase tool wear during drilling and routing processes, potentially increasing manufacturing costs.

The Cost Factor

Pure PTFE is already a premium material. The addition of specialized, high-performance fillers and complex manufacturing processes required to create a uniform composite further increases the final cost of the laminate.

Making the Right Choice for Your Goal

Your choice of PTFE laminate should be driven by the most critical performance requirement of your application.

- If your primary focus is signal integrity at high frequencies: Prioritize laminates with ceramic fillers engineered to provide a stable, low dielectric constant.

- If your primary focus is mechanical stability and durability: Select a material with a high percentage of woven glass reinforcement to minimize expansion and warping.

- If your primary focus is thermal management for high-power components: Look for laminates specifically engineered with thermally conductive fillers to dissipate heat effectively.

- If your primary focus is meeting safety and flammability standards: Ensure the material datasheet explicitly lists flame retardant additives and compliance with ratings like UL 94 V-0.

Ultimately, understanding these additives allows you to move beyond a generic material choice and select a precisely engineered composite that meets your specific performance targets.

Summary Table:

| Additive Category | Common Materials | Primary Purpose |

|---|---|---|

| Reinforcements | Woven glass, aramid fibers | Increase rigidity and dimensional stability, reduce warping. |

| Fillers | Ceramics, metals | Control dielectric constant (Dk), improve thermal conductivity, lower CTE. |

| Binders/Stabilizers | Resins, flame retardants | Improve layer bonding, meet safety standards (e.g., UL 94 V-0), ensure longevity. |

Need a PTFE Laminate Engineered for Your Specific Requirements?

Choosing the right material composite is critical for the success of your high-frequency, high-power, or mechanically demanding application. KINTEK specializes in the precision manufacturing of advanced PTFE components, including custom laminates.

We work with engineers in the semiconductor, medical, laboratory, and industrial sectors to develop solutions that balance mechanical strength, thermal management, and signal integrity. From initial prototypes to high-volume production, our expertise ensures your components perform reliably.

Let us help you optimize your design. Contact our team today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the applications of expanded PTFE? Unlock Versatility for Demanding Seals & Filters

- What recent advancements have been made in PTFE expansion joint technology? Enhance Durability & Precision

- What role does PTFE play in vibration dampening in piping systems? | Reduce Stress & Wear

- What makes PTFE special in terms of friction? Achieve Unmatched Efficiency with Self-Lubricating Components

- How do PTFE expansion joints contribute to sustainability? Enhance Long-Term System Integrity & Environmental Safety

- How do PTFE gaskets prevent the ingress of corrosive fluids into seals? Achieve Unmatched Chemical Containment

- How is PTFE utilized in the food and beverage industry? Ensuring Safety and Efficiency

- In what types of environments are PTFE envelope gaskets effective? Superior Sealing for Corrosive & Delicate Flange Systems