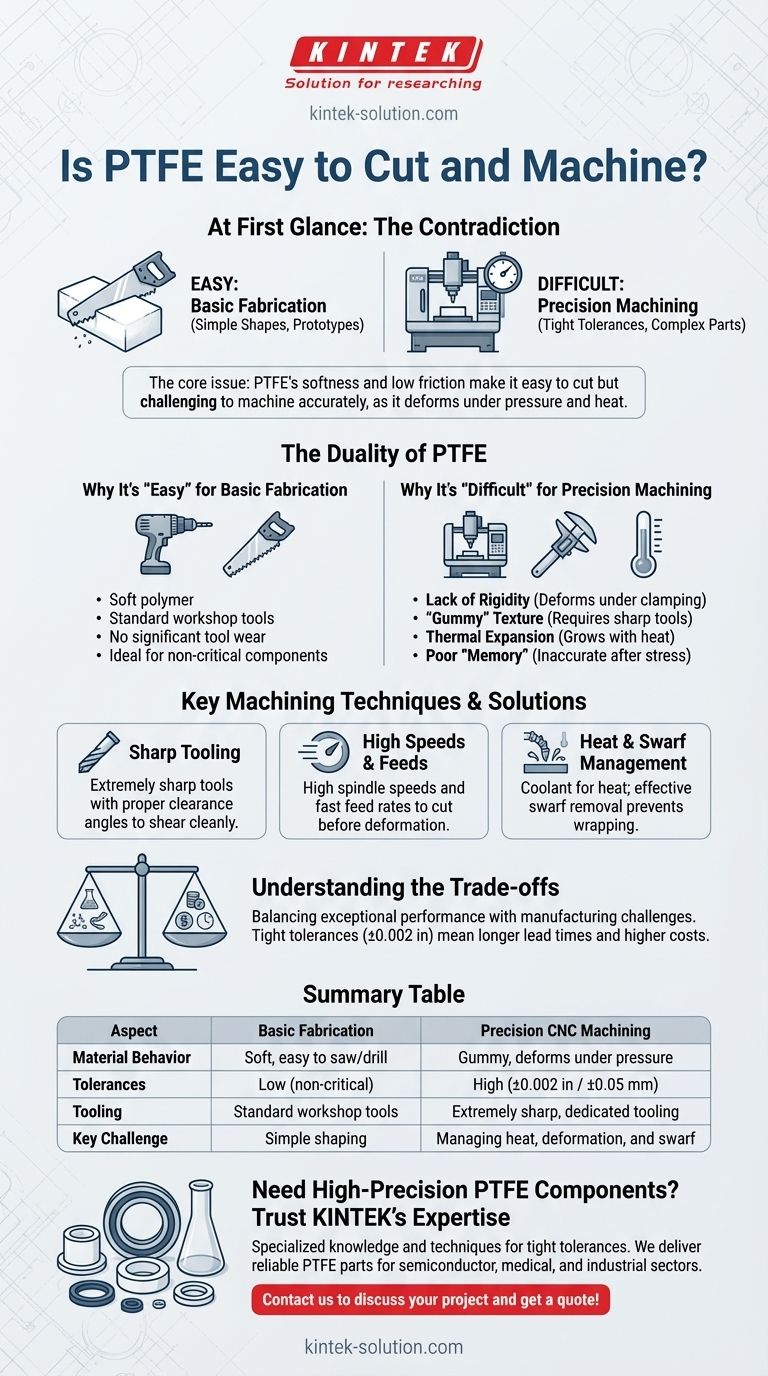

At first glance, the answer appears contradictory. While PTFE (Polytetrafluoroethylene) is soft and can be easily cut, sawed, or drilled with basic tools, it is a notoriously difficult material to machine to high-precision standards. Its unique properties make it easy to work with for simple shapes but challenging for achieving tight tolerances.

The core issue with PTFE is that the very properties that make it useful—its softness and low friction—also make it difficult to machine accurately. The material easily deforms under pressure and heat, requiring specialized techniques to achieve precise results.

The Duality of PTFE: Soft vs. Difficult

PTFE's reputation for being both easy and hard to work with stems from the difference between rough cutting and precision machining. Understanding this duality is key to planning a successful project.

Why It's "Easy" for Basic Fabrication

PTFE is a relatively soft polymer. For prototypes, non-critical components, or manual adjustments, it does not demand specialized equipment.

You can readily cut sheets and rods using standard workshop tools like saws and drills without causing significant tool wear.

Why It's "Difficult" for Precision Machining

The challenge arises when you need to hold tight tolerances, typically with CNC equipment. The material's inherent properties work against the machinist.

- Lack of Rigidity: PTFE is soft and will compress or deform under the pressure of clamps in a vise. It also flexes away from the cutting tool, making it difficult to hold dimensions accurately.

- "Gummy" Texture: Unlike metals that produce clean chips, PTFE can be "gummy." This requires extremely sharp tooling and high feed rates to get a clean cut rather than just pushing the material around.

- Thermal Expansion: The material expands and contracts significantly with temperature changes. Heat generated during aggressive cutting can cause the part to grow, leading to inaccurate final dimensions once it cools.

- Poor "Memory": If PTFE is stressed or deformed during machining, it does not readily spring back to its original shape, which can lock in inaccuracies.

Key Machining Techniques and Considerations

Despite the challenges, skilled machinists can produce highly accurate PTFE parts. This requires specific strategies to counteract the material's difficult properties.

CNC Milling and Turning

CNC milling is used for complex shapes and features, while CNC turning is ideal for cylindrical parts like seals, rings, and bushings. Both require a specific approach.

The Importance of Tooling and Speed

Success with PTFE hinges on technique. Machinists must use extremely sharp tools with proper clearance angles to shear the material cleanly.

High spindle speeds and fast feed rates are critical. This approach ensures the tool is cutting the material before it has a chance to deform or melt.

Managing Heat and Swarf

For heat-intensive operations, a coolant may be necessary to prevent thermal expansion. Effective swarf (chip) removal is also crucial to prevent chips from wrapping around the tool and marring the part's surface.

Understanding the Trade-offs

Choosing PTFE means balancing its exceptional performance characteristics against its manufacturing complexity.

The Challenge of Tight Tolerances

While skilled machinists can hold tolerances within ±0.002 inches (±0.05 mm), doing so is more complex and time-consuming than with a rigid material like aluminum or PEEK.

This difficulty often translates into longer lead times and higher costs for custom-machined PTFE parts, especially for intricate designs.

"No Special Tools" is Misleading

The idea that you don't need "special tools" applies only to rough, manual work. For precision CNC machining, while the tools may be standard types (e.g., end mills), they must be in pristine condition—perfectly sharp and smooth—and often dedicated solely to plastics.

Making the Right Choice for Your Project

Use your end-goal to determine if PTFE's machining challenges are a significant hurdle for your application.

- If your primary focus is a simple prototype or a low-tolerance gasket: PTFE is an excellent, easy-to-use material that you can likely work with using standard shop tools.

- If your primary focus is a high-precision component like a bearing or tight-fitting seal: PTFE is a great functional choice, but budget for the cost and lead time associated with an experienced machinist who specializes in soft polymers.

- If your primary focus is chemical inertness or temperature resistance: PTFE is one of the best materials available, but you must design the part with its machining limitations in mind to ensure feasibility.

Ultimately, successfully using PTFE is about balancing its incredible material benefits with the realities of its manufacturing process.

Summary Table:

| Aspect | Basic Fabrication | Precision CNC Machining |

|---|---|---|

| Material Behavior | Soft, easy to saw/drill | Gummy, deforms under pressure |

| Tolerances | Low (non-critical) | High (±0.002 in / ±0.05 mm) |

| Tooling | Standard workshop tools | Extremely sharp, dedicated tooling |

| Key Challenge | Simple shaping | Managing heat, deformation, and swarf |

Need High-Precision PTFE Components? Trust KINTEK's Expertise

Machining PTFE to exact specifications requires specialized knowledge and techniques to overcome its unique challenges. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors.

We combine sharp tooling, optimized feeds and speeds, and rigorous quality control to deliver parts that meet your tightest tolerances. Whether you need prototypes or high-volume production, we ensure your PTFE parts perform reliably in critical applications.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What should be considered regarding surface compatibility when using PTFE washers? Ensuring a Reliable Seal in Demanding Applications

- What are the characteristics of graphite PTFE gland packings? High-Performance Sealing for Demanding Applications

- What are the main disadvantages of virgin PTFE products in fluid sealing applications? Overcoming Creep and Cold Flow

- What does PTFE stand for in control valves? A Guide to Chemical Resistance and Purity

- Why are ePTFE gaskets considered hygienic? Ensure Product Purity with a Reliable Seal

- How are PTFE gaskets used in the petrochemical industry? Ensure Leak-Proof Seals for Aggressive Chemicals

- Why is PTFE used in electrical components? Unmatched Insulation for Extreme Environments

- What are other names for Teflon encapsulated silicone o-rings? Find the Right High-Performance Seal