In short, PTFE piston seals are primarily utilized in demanding hydraulic and pneumatic systems. Their selection is driven by the need for reliable sealing under conditions of high pressure, significant mechanical stress, extreme temperatures, and exposure to aggressive chemicals where lesser materials would quickly fail.

The core reason PTFE (often known by the brand name Teflon) is so widely adopted is its unique combination of properties. It is not just one feature, but the simultaneous presence of chemical inertness, a wide operating temperature range, and excellent sliding characteristics that makes it a default choice for the most challenging industrial applications.

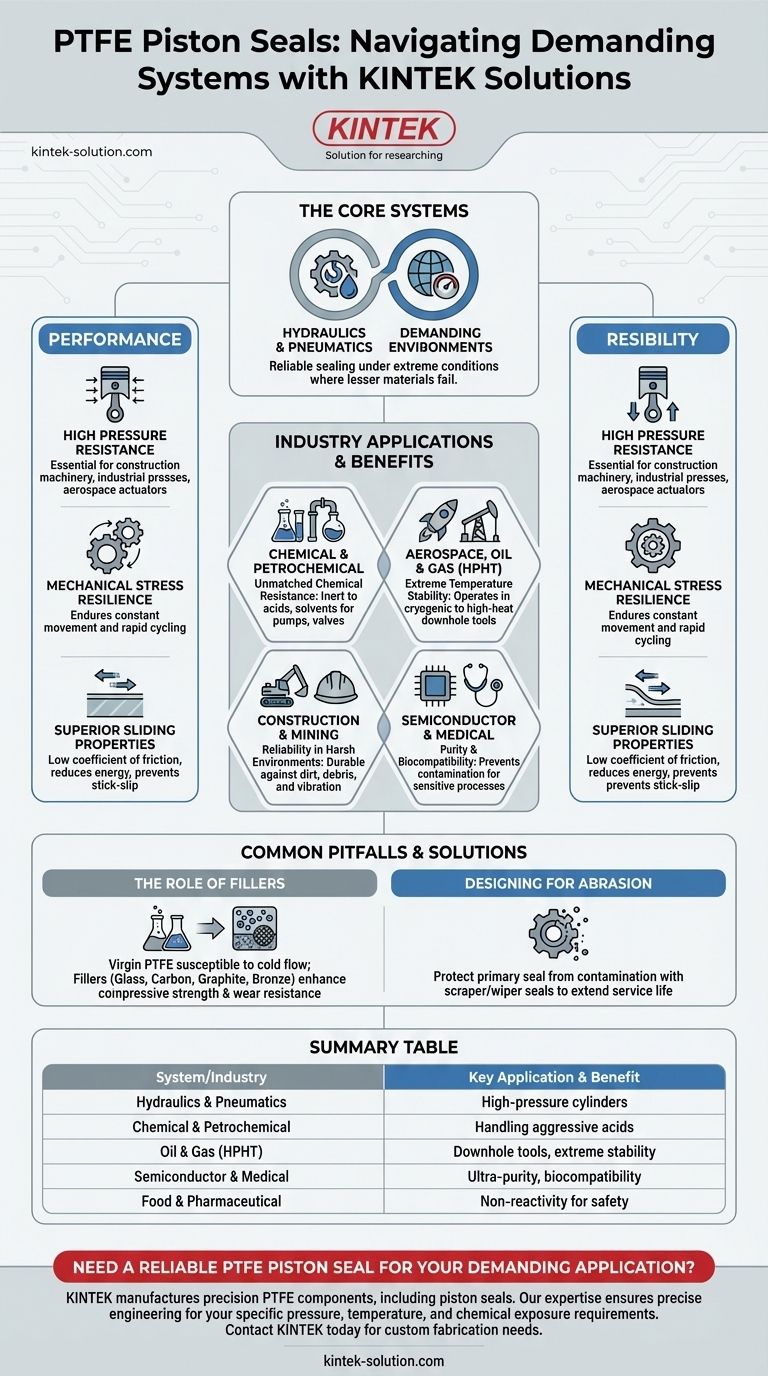

The Primary Systems: Hydraulics and Pneumatics

PTFE piston seals are foundational components in fluid power systems. Their primary function is to seal the pressure between a piston and a cylinder bore, ensuring that hydraulic fluid or compressed air is used efficiently to generate force and motion.

Performance Under High Pressure

PTFE seals are engineered to withstand the extreme pressures common in modern hydraulic equipment. This makes them essential for cylinders in construction machinery, industrial presses, and aerospace actuators.

Resilience to Mechanical Stress

In addition to pressure, these seals must endure the constant mechanical stress of movement and friction. The inherent toughness of PTFE ensures a long service life even in rapid-cycling applications.

Superior Sliding Properties

PTFE has an exceptionally low coefficient of friction. This "slipperiness" reduces the energy required to move the piston, prevents stick-slip phenomena, and minimizes wear on both the seal and the cylinder.

Why PTFE Is Chosen Across Diverse Industries

While hydraulics and pneumatics are the systems, the choice of PTFE is driven by the specific environmental challenges found in a vast range of industries.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This property makes it indispensable in the chemical and petrochemical industries, as well as in food production and pharmaceutical manufacturing, where seals cannot react with the process media.

Extreme Temperature Stability

These seals maintain their integrity and performance across an exceptionally wide temperature range. This is critical in aerospace (pumps, engines, brakes), cryogenic liquid control, and oil and gas exploration, especially in high-pressure, high-temperature (HPHT) downhole tools.

Reliability in Harsh Operational Environments

PTFE's durability makes it a go-to choice for applications where failure is not an option. This includes construction and heavy mobile equipment (excavators, loaders), automotive manufacturing, and mining, where seals are exposed to dirt, debris, and constant vibration.

Purity and Biocompatibility

For highly sensitive applications, PTFE is a perfect fit. In semiconductor manufacturing, its purity prevents contamination. In medical applications like surgical tools and analyzers, its biocompatibility ensures it is safe for use.

Common Pitfalls to Avoid

While PTFE is a superior material, its application requires careful consideration to avoid common points of failure. Understanding its limitations is key to successful implementation.

The Critical Role of Fillers

Pure, or "virgin," PTFE can be susceptible to cold flow (creep) under load and has moderate wear resistance. To counteract this, PTFE is often blended with fillers like glass fiber, carbon, graphite, or bronze. These fillers dramatically enhance compressive strength, wear resistance, and thermal conductivity to match the specific demands of an application.

Designing for Abrasion and Contamination

In environments with abrasive particles, such as the mining or cement industries, even filled PTFE can wear prematurely. Proper system design, including the use of scraper or wiper seals to protect the primary piston seal from contamination, is essential for extending service life.

How to Apply This to Your System

Your specific goal will determine whether a PTFE-based seal is the correct choice and which formulation is most appropriate.

- If your primary focus is chemical compatibility: A virgin or glass-filled PTFE seal is likely the best choice for handling aggressive media in chemical pumps or food processing.

- If your primary focus is high pressure and wear resistance: A bronze-filled or carbon-filled PTFE seal is engineered for the demanding cycles of hydraulic presses and construction equipment.

- If your primary focus is a wide temperature range: Specific PTFE compounds are designed to perform reliably in everything from cryogenic components to high-temperature aerospace engine systems.

- If your primary focus is purity or biocompatibility: Virgin PTFE is the standard for medical devices, semiconductor manufacturing, and pharmaceutical production lines.

Ultimately, selecting a PTFE piston seal is a decision to prioritize reliability in environments where other materials would compromise performance.

Summary Table:

| System / Industry | Key Application & Benefit |

|---|---|

| Hydraulics & Pneumatics | High-pressure cylinders in construction, industrial presses, and aerospace actuators for reliable force generation. |

| Chemical & Petrochemical | Seals for pumps and valves handling aggressive acids and solvents due to PTFE's chemical inertness. |

| Oil & Gas (HPHT) | Downhole tools and components requiring stability in extreme high-pressure, high-temperature environments. |

| Semiconductor & Medical | Applications demanding ultra-purity and biocompatibility, such as semiconductor manufacturing and surgical tools. |

| Food & Pharmaceutical | Seals for production lines where non-reactivity with process media is essential for safety and purity. |

Need a Reliable PTFE Piston Seal for Your Demanding Application?

PTFE seals are not all the same. The right formulation—whether virgin PTFE for purity or a filled compound for extreme pressure and wear resistance—is critical to your system's success and longevity.

KINTEK manufactures precision PTFE components, including piston seals, for the most challenging environments. We serve the semiconductor, medical, laboratory, industrial, and other specialized industries. Our expertise ensures you get a seal that is precisely engineered for your specific pressure, temperature, and chemical exposure requirements.

Let us provide you with a solution that enhances performance and prevents costly downtime.

Contact KINTEK today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability