In short, Teflon (PTFE) seals are used in nearly every demanding industrial sector, including chemical processing, aerospace, automotive, pharmaceutical, and oil and gas. Their widespread adoption is due to a unique combination of chemical inertness, the ability to withstand extreme temperatures, and an exceptionally low coefficient of friction.

The core reason for Teflon's ubiquity is not just one feature, but its rare ability to solve three critical engineering challenges at once: resisting corrosive chemicals, tolerating extreme temperatures, and reducing friction in moving parts.

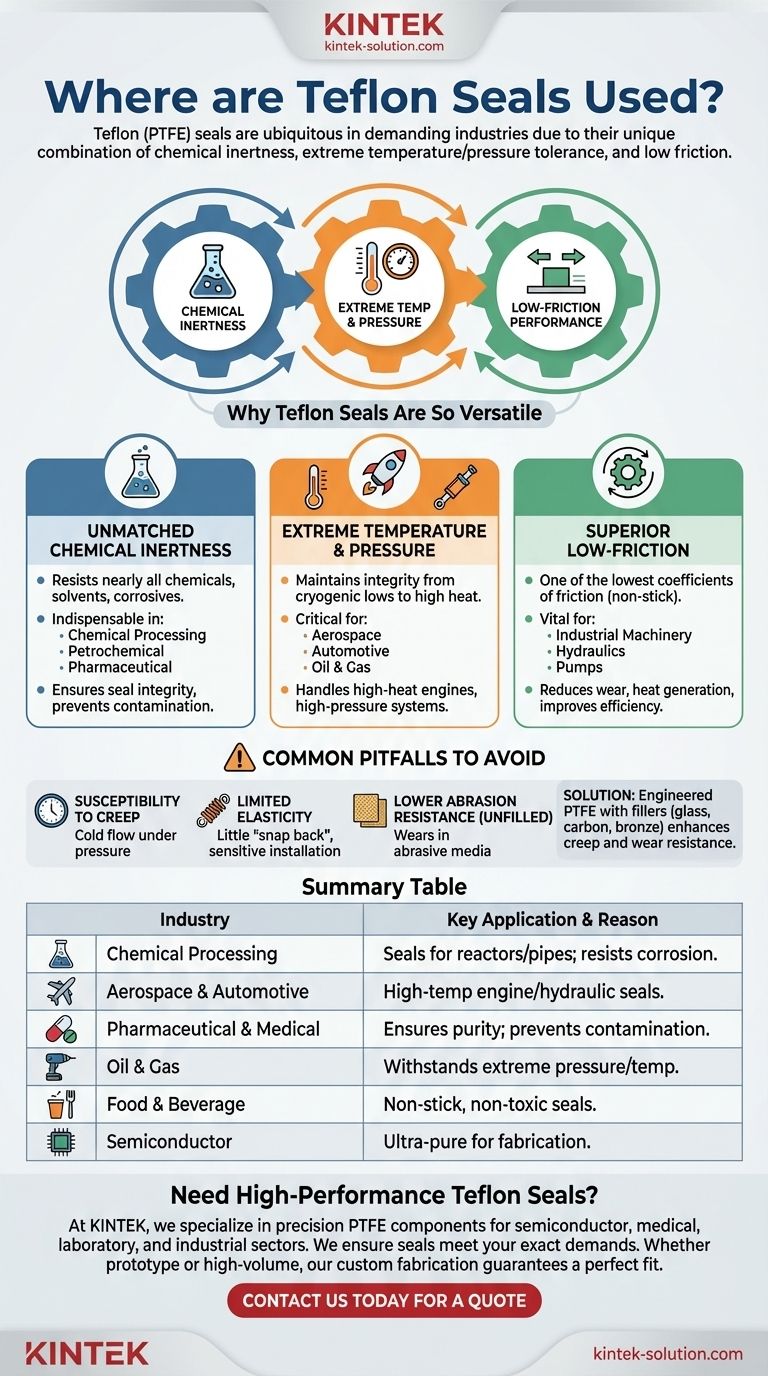

Why Teflon Seals Are So Versatile

The use of Teflon seals across such diverse industries is driven by a specific set of high-performance material properties. Understanding these properties explains why this material is often the only viable choice for a given application.

Unmatched Chemical Inertness

Teflon (PTFE) is famously non-reactive. It can withstand nearly all industrial chemicals, solvents, and corrosive substances without degrading.

This makes it indispensable in the chemical processing, petrochemical, and pharmaceutical industries, where it ensures seal integrity and prevents contamination of pure products.

Extreme Temperature and Pressure Tolerance

PTFE seals maintain their structural integrity across a vast temperature range, from cryogenic lows to highs exceeding what most elastomeric (rubber) seals can handle.

This property is critical for aerospace, automotive, and oil & gas applications, where seals are exposed to high-heat engine components, high-pressure hydraulic systems, and harsh downhole drilling environments.

Superior Low-Friction Performance

Teflon has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. This is vital for dynamic sealing applications involving moving parts.

In industrial machinery, hydraulics, pumps, and gearboxes, this reduces wear and tear, minimizes heat generation, and improves the overall efficiency of the equipment.

Purity and Non-Contamination

Because PTFE is inert and does not degrade or shed particles easily, it meets stringent purity standards.

This is non-negotiable in food and beverage processing, pharmaceutical manufacturing, and semiconductor fabrication, where preventing product contamination is the highest priority.

Common Pitfalls to Avoid

While highly effective, Teflon seals are not a universal solution. Their unique properties come with specific trade-offs that are critical to understand for successful implementation.

Susceptibility to Creep

Under constant pressure and temperature, pure PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This can lead to a loss of sealing force.

Engineered PTFE seals often include fillers like glass, carbon, or bronze to drastically improve creep resistance for demanding applications.

Limited Elasticity

Compared to rubber seals, PTFE has very little elasticity. It does not "snap back" into shape easily.

This makes installation more sensitive. A PTFE seal that is stretched or nicked during installation may not seal effectively, requiring careful handling and proper tooling.

Lower Abrasion Resistance (Unfilled)

Basic, unfilled PTFE is relatively soft and can wear down quickly in applications with abrasive media.

Again, the use of specialized fillers is the standard solution to enhance the material's wear and abrasion resistance for sealing in challenging environments.

Making the Right Choice for Your Application

Selecting a seal material requires matching its properties to the operational demands of the system.

- If your primary focus is resisting aggressive chemicals: Teflon is almost always the default choice due to its near-universal chemical inertness.

- If your primary focus is high-temperature environments: PTFE seals provide a reliable solution where conventional elastomers would fail.

- If your primary focus is low-friction dynamic sealing: The non-stick nature of PTFE is ideal for rotating shafts, pistons, and other moving components.

Ultimately, the right seal is the one whose material characteristics are best suited to overcome the specific challenges of its environment.

Summary Table:

| Industry | Key Application & Reason |

|---|---|

| Chemical Processing | Seals for reactors, pipes; resists corrosive chemicals. |

| Aerospace & Automotive | High-temperature engine and hydraulic system seals. |

| Pharmaceutical & Medical | Ensures product purity and prevents contamination. |

| Oil & Gas | Withstands extreme pressure and temperature in drilling. |

| Food & Beverage | Non-stick, non-toxic seals for processing equipment. |

| Semiconductor | Ultra-pure seals for contamination-sensitive fabrication. |

Need high-performance Teflon seals for your industry?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We ensure your seals meet the exact demands of your application—from chemical resistance to extreme temperature tolerance.

Whether you require a custom prototype or a high-volume order, our expertise in custom fabrication guarantees a perfect fit and superior performance.

Contact us today to discuss your specific sealing requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Can a Teflon sheet be used for sublimation printing? Enhance Print Quality & Protect Equipment

- In what applications are PTFE balls commonly used? Key Uses in Chemical, Medical & Industrial Systems

- How do PTFE lined valves ensure longevity in harsh chemical environments? Achieve Decades of Reliable Service

- What are the advantages of spring energized PTFE seals? Unmatched Reliability in Extreme Conditions

- What industries commonly use PTFE Bellow Mechanical Seals? The Ultimate Guide for Corrosive & Pure Fluid Handling

- What are the main benefits of PTFE envelope gaskets? Achieve Superior Chemical Resistance and Sealing Integrity

- What material is used to make PTFE flange gaskets? Choose the Right PTFE for Your Sealing Needs

- How does hydrothermal corrosion affect PTFE sliding bearings? Uncover the Two-Pronged Attack