In short, PTFE-lined piping systems are predominantly used in industries where fluids are either extremely corrosive or must remain exceptionally pure. The most common sectors include chemical and petrochemical processing, pharmaceutical manufacturing, semiconductor fabrication, and advanced water treatment.

The core decision to use a PTFE-lined system is driven by a need for absolute reliability in harsh environments. It's a solution chosen when the cost of failure—due to corrosion or contamination—far outweighs the initial investment in the piping itself.

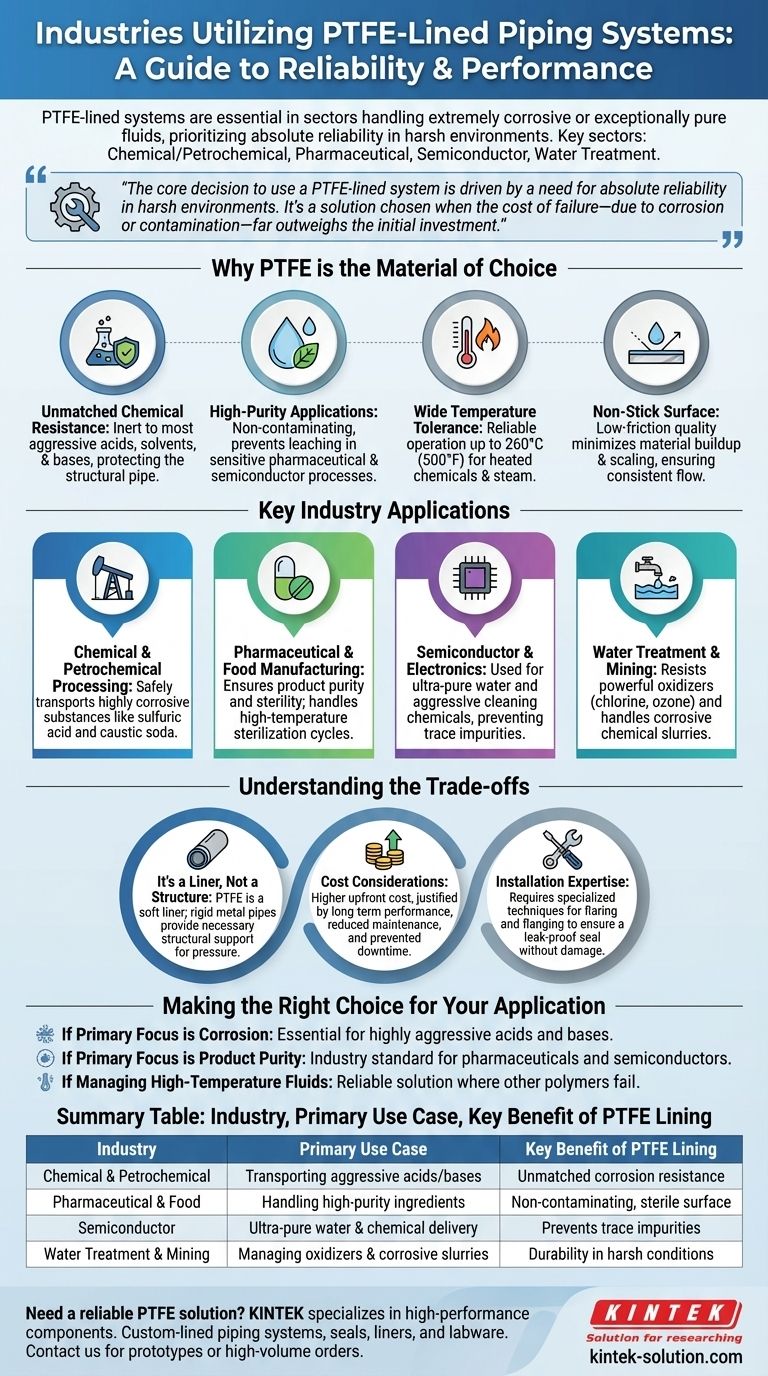

Why PTFE is the Material of Choice

The widespread adoption of PTFE (Polytetrafluoroethylene) as a pipe liner isn't accidental. It stems from a unique combination of material properties that solve critical engineering challenges.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is virtually immune to attack from aggressive acids, solvents, and bases across a wide range of concentrations.

This extreme resistance prevents the pipe's structural housing (typically carbon or stainless steel) from being destroyed by the corrosive media it transports.

High-Purity Applications

The material is inherently non-contaminating. PTFE does not leach or release particles into the fluid it carries, which is an absolute requirement in sensitive processes.

This property is critical in the pharmaceutical industry, where product purity is paramount, and in semiconductor manufacturing, where even trace impurities in ultra-pure water can ruin microchips.

Wide Temperature Tolerance

PTFE-lined systems can operate reliably at very high temperatures, often up to 260°C (500°F).

This allows them to handle demanding industrial processes involving heated chemicals or steam without degrading, which would be impossible for many standard plastic or even some metal piping systems.

Non-Stick Surface

PTFE is famous for its low-friction, non-stick surface. In a piping system, this reduces the potential for material buildup or scaling on the pipe walls.

This ensures consistent flow rates and minimizes the risk of blockages, a valuable trait in pulp and paper or certain chemical manufacturing applications.

Key Industry Applications in Detail

Understanding the "why" clarifies why specific industries rely so heavily on these systems.

Chemical and Petrochemical Processing

These industries routinely handle some of the most corrosive substances, such as sulfuric acid, hydrochloric acid, and caustic soda. PTFE-lined piping is the default choice for safely transporting these fluids, ensuring both plant safety and equipment longevity.

Pharmaceutical and Food Manufacturing

Here, the primary concern is preventing product contamination. PTFE-lined pipes, valves, and fittings ensure that the final product remains pure and meets strict regulatory standards. Its ability to handle high-temperature sterilization cycles is also a key advantage.

Semiconductor and Electronics

The fabrication of microchips requires vast quantities of ultra-pure water and aggressive cleaning chemicals. PTFE is one of the few materials clean enough to not introduce ionic or organic contaminants that could cause defects in the silicon wafers.

Water Treatment and Mining

In municipal and industrial water treatment, chemicals like chlorine or ozone are used for disinfection. PTFE resists degradation from these powerful oxidizers. In mining, it's used to handle the corrosive chemical slurries involved in ore extraction and processing.

Understanding the Trade-offs

While highly effective, PTFE-lined systems are a specialized solution with specific considerations.

It's a Liner, Not a Structure

PTFE is a relatively soft material with low mechanical strength. It cannot serve as a standalone pipe under pressure.

This is precisely why it is used as a liner inside a rigid metal pipe (like steel), which provides the necessary structural support to handle pressure and external loads.

Cost Considerations

These systems represent a higher upfront cost compared to standard carbon steel or basic plastic piping.

The investment is justified by its long-term performance, reduced maintenance, and the prevention of costly failures and downtime in critical processes.

Installation Expertise

Proper installation is crucial. The flaring and flanging of PTFE-lined components require specialized techniques to ensure a leak-proof seal without damaging the liner. Improper handling can compromise the entire system.

Making the Right Choice for Your Application

Selecting the correct piping material is a critical engineering decision based on the specific demands of the fluid and process.

- If your primary focus is corrosion: A PTFE-lined system is essential for safely handling highly aggressive acids, bases, or specialty chemicals.

- If your primary focus is product purity: PTFE is the industry standard in pharmaceuticals and semiconductors to prevent leaching and contamination.

- If you manage high-temperature fluids: PTFE's thermal stability provides a reliable solution where other polymers would fail.

Ultimately, choosing a PTFE-lined system is an investment in process integrity, safety, and long-term operational reliability.

Summary Table:

| Industry | Primary Use Case | Key Benefit of PTFE Lining |

|---|---|---|

| Chemical & Petrochemical | Transporting aggressive acids/bases | Unmatched corrosion resistance |

| Pharmaceutical & Food | Handling high-purity ingredients | Non-contaminating, sterile surface |

| Semiconductor | Ultra-pure water & chemical delivery | Prevents trace impurities |

| Water Treatment & Mining | Managing oxidizers & corrosive slurries | Durability in harsh conditions |

Need a reliable PTFE solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined piping systems, seals, liners, and labware. Our precision production ensures your systems withstand corrosive chemicals, maintain product purity, and operate reliably at high temperatures—protecting your processes in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype or a high-volume order, our custom fabrication expertise delivers the integrity your application demands.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the extreme working conditions that PTFE Lip Seals can withstand? Handle -60°C to 200°C & 60 m/s

- Why is it important to specify reinforcement requirements when selecting PTFE materials? Ensure Component Performance & Reliability

- What raw material is used to manufacture PTFE spacers? Discover the Power of Teflon for High-Performance Components

- What makes PTFE butterfly valves special compared to other types? Unmatched Chemical & Thermal Performance

- What makes PTFE bushes suitable for corrosive environments? Unmatched Chemical Resistance and Reliability

- In what applications is PTFE commonly used due to its chemical resistance? Essential for Chemical, Pharma, and Oil & Gas

- What are the components of an assembly PTFE sliding bearing pad? A Guide to the Engineered System

- What are the advantages of spring-energized PTFE seals? Achieve Superior Sealing in Extreme Conditions