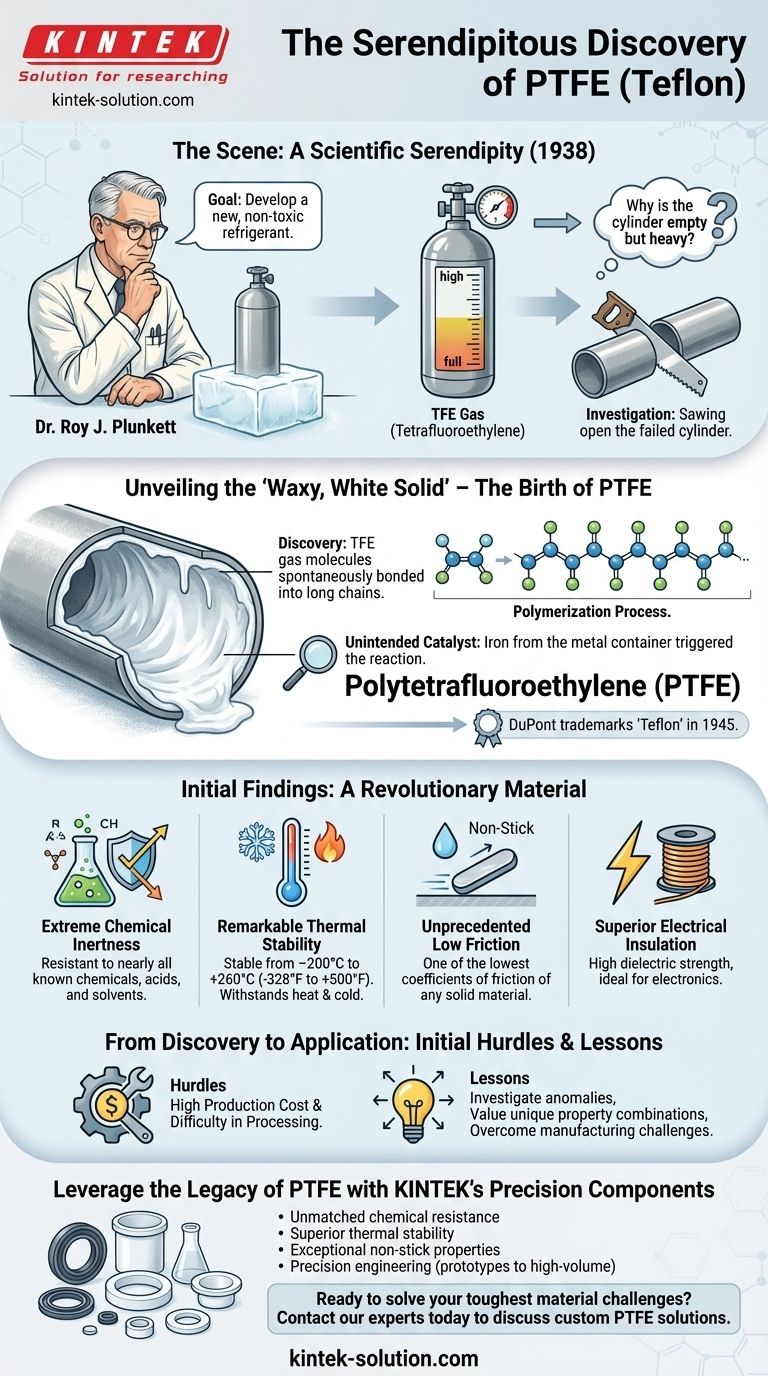

In a classic case of scientific serendipity, Polytetrafluoroethylene (PTFE) was discovered entirely by accident. In 1938, Dr. Roy J. Plunkett, a chemist at DuPont, was attempting to develop a new, non-toxic refrigerant. When a pressurized cylinder of tetrafluoroethylene gas appeared to be empty despite its weight, he investigated and found the gas had transformed into a strange, waxy white solid with a remarkable set of properties.

The discovery of PTFE was not just a lucky accident, but a lesson in the power of scientific curiosity. Plunkett's decision to investigate a failed experiment, rather than simply discard it, revealed a material whose unique combination of extreme inertness and low friction was immediately recognized as revolutionary.

The Scene of the Discovery: A Failed Experiment

The journey to PTFE began not with a goal to create a non-stick coating, but with a completely different objective.

The Goal: A New Refrigerant

In 1938, Dr. Plunkett was working to create a new chlorofluorocarbon (CFC) refrigerant. His process involved using tetrafluoroethylene (TFE) gas, which he stored in small, pressurized metal cylinders.

The Anomaly: A Pressurized Can with No Gas

One morning, Plunkett and his assistant prepared to use a cylinder of TFE that had been stored on dry ice. Although the cylinder's weight indicated it was still full of gas, no gas would come out when the valve was opened. The pressure had dropped to zero.

The Pivotal Decision: Investigating the Failure

Instead of setting the seemingly faulty cylinder aside, Plunkett’s curiosity took over. He and his assistant made the crucial decision to saw the metal cylinder open to understand what had happened inside.

Unveiling a Revolutionary Material

What they found inside the cylinder was not an empty space, but a substance that would change material science forever.

The "Waxy, White Solid"

The interior of the cylinder was coated with a slippery, waxy white powder. The TFE gas molecules had spontaneously bonded together into long chains, a process known as polymerization.

An Unintended Catalyst

It is believed that the iron from the internal surface of the metal container acted as an unintended catalyst, helping to trigger the polymerization reaction that transformed the TFE gas into a solid.

The Birth of Polytetrafluoroethylene (PTFE)

This new substance was polytetrafluoroethylene, or PTFE. DuPont later registered the trademark Teflon for this material in 1945.

The Initial Findings: A Unique Set of Properties

The lab team at DuPont immediately began testing the strange new substance and quickly realized they had something extraordinary. Its properties were unlike those of any other known material.

Extreme Chemical Inertness

Early tests revealed the material was astonishingly resistant to corrosion from nearly every known chemical, acid, and solvent.

Remarkable Thermal Stability

PTFE demonstrated a very high melting point and an incredibly wide operating temperature range. It could withstand both extreme heat and cold, remaining stable from approximately –200° C to +260° C (–328° F to +500° F).

Unprecedented Low Friction

Perhaps its most famous quality, the material was incredibly slippery. It was found to have one of the lowest coefficients of friction of any solid material ever measured, giving it its signature "non-stick" property.

Superior Electrical Insulation

The new polymer was also an excellent electrical insulator, possessing high dielectric strength. This made it immediately valuable for electronics and high-frequency applications.

From Discovery to Application: The Initial Hurdles

Despite its incredible properties, PTFE was not an overnight commercial success. Its unique nature also made it exceptionally difficult to work with.

High Production Cost

The initial polymerization process was difficult to control and expensive, which meant the material was not initially viable for consumer products. Its first major use was in the Manhattan Project for sealing gaskets that had to resist highly corrosive materials.

Difficulty in Processing

A material that resists heat and doesn't stick to anything is also incredibly challenging to mold or form into useful shapes. New manufacturing techniques had to be invented before PTFE could be applied as a coating to cookware and other commercial goods.

Lessons from the Discovery of PTFE

The story of PTFE offers several key insights that remain relevant today for science, engineering, and innovation.

- If your primary focus is on innovation: Remember that breakthroughs often come from investigating anomalies and failures, not just from succeeding at the original goal.

- If your primary focus is on material science: Recognize that a material's value is defined by its unique combination of properties; PTFE's power comes from having heat resistance, chemical inertness, and low friction all at once.

- If your primary focus is on product development: Understand that a revolutionary material is not enough; overcoming the challenges of cost and manufacturing is what unlocks its widespread potential.

The discovery of PTFE is a powerful reminder that scientific curiosity, when applied to unexpected results, can truly change the world.

Summary Table:

| Key Finding | Initial Property Identified |

|---|---|

| Chemical Resistance | Extreme inertness to acids and solvents |

| Thermal Stability | Stable from -200°C to +260°C |

| Low Friction | One of the lowest coefficients of friction |

| Electrical Insulation | High dielectric strength for electronics |

Leverage the Legacy of PTFE with KINTEK's Precision Components

At KINTEK, we build upon the revolutionary discovery of PTFE by manufacturing high-performance components that harness its unique properties for your most demanding applications. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE seals, liners, and labware offer:

- Unmatched chemical resistance for corrosive environments

- Superior thermal stability across extreme temperature ranges

- Exceptional non-stick properties for contamination-free operations

- Precision engineering from prototypes to high-volume production runs

Ready to solve your toughest material challenges? Contact our experts today to discuss how our custom PTFE solutions can enhance your product performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What does PTFE stand for and what is its chemical composition? Unlock the Secrets of a High-Performance Polymer

- Why can't PTFE be processed using conventional polymer techniques? Discover the Sintering Solution

- What is PTFE and what are its primary characteristics? The Ultimate High-Performance Polymer

- What is Expanded PTFE and how does it differ from regular PTFE? Choosing the Right Material for Your Application

- What are the common applications of PTFE in aggressive chemical environments? Ensure Reliability and Safety

- How was PTFE discovered and when was it patented? The Accidental Invention of Teflon

- How can waste from PTFE manufacturing be reused? Transform Scrap into High-Performance Micropowder

- What are the advantages of PTFE in chemical processing applications? Ensure Safety, Purity, and Reliability