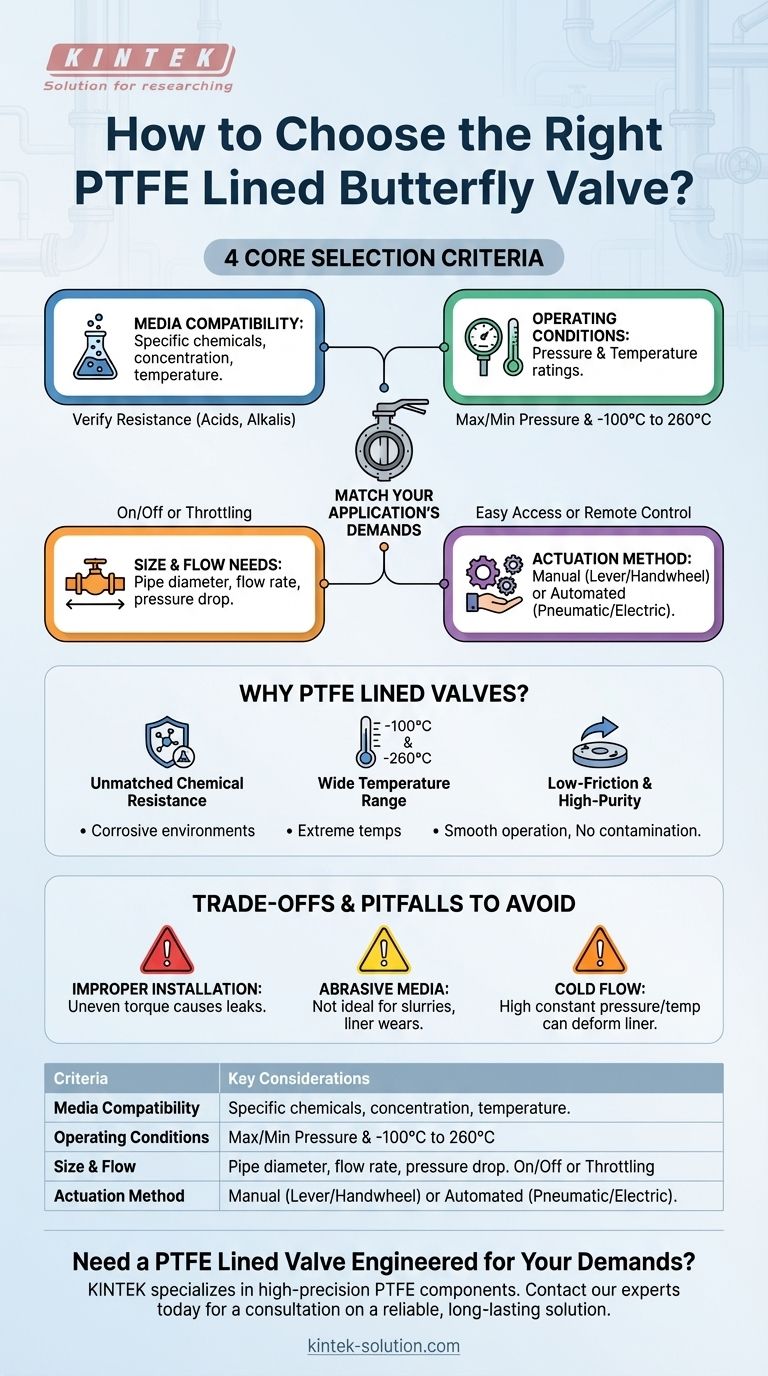

To choose the right PTFE lined butterfly valve, you must evaluate four core criteria: the specific media compatibility, the system's operating conditions (pressure and temperature), the required valve size and flow characteristics, and the necessary actuation method. This ensures the valve's exceptional chemical resistance is matched perfectly to the physical demands of your application.

Selecting the right valve is not just about matching a spec sheet. The goal is to choose a valve where the PTFE liner's chemical resilience is precisely aligned with your system's physical demands, ensuring long-term, leak-free reliability without unnecessary over-engineering.

Why Choose a PTFE Lined Valve?

Before diving into selection criteria, it's crucial to understand the fundamental advantages that make PTFE lined valves a specialized and powerful solution. Their value stems directly from the properties of Polytetrafluoroethylene (PTFE).

Unmatched Chemical Resistance

The primary benefit of a PTFE liner is its role as a protective barrier. It is exceptionally resistant to a wide range of corrosive media, including strong acids, alkalis, and oxidants, making it ideal for harsh chemical processing environments.

Wide Temperature Range

PTFE performs reliably across a vast temperature spectrum. It can withstand high temperatures up to 260°C (500°F) and remains functional and soft at cryogenic temperatures as low as -100°C (-148°F).

Low-Friction Operation

PTFE has an extremely low coefficient of friction. This property ensures smoother, easier operation of the valve disc, which reduces the torque required for actuation and minimizes wear on the valve's moving parts over its lifespan.

Suitability for High-Purity Applications

Because PTFE is an inert material, it does not contaminate the media flowing through it. This makes these valves a standard choice for industries like pharmaceuticals, food and beverage, and water treatment, where media purity is critical.

A Systematic Approach to Valve Selection

To ensure you choose the correct valve, follow a methodical process that addresses the key technical and operational requirements of your system.

Step 1: Verify Media Compatibility

This is the most critical step. While PTFE is broadly resistant, you must confirm that it is compatible with the specific chemical, its concentration, and its temperature in your pipeline. Always consult the manufacturer's chemical compatibility charts.

Step 2: Define Operating Conditions

A valve is a complete assembly, and its limits are defined by more than just the liner. You must evaluate the system's maximum and minimum pressure and temperature ratings. The valve body, stem, and seals must be able to withstand these conditions without compromising structural integrity.

Step 3: Determine the Correct Size and Flow Needs

The valve size must match your pipe diameter, but it also depends on the required flow rate and the allowable pressure drop across the valve. Butterfly valves are effective for both simple on/off isolation and for regulating (or throttling) the flow of media.

Step 4: Choose the Actuation Method

Decide whether your application requires manual or automated operation.

- Manual operation (using a lever or handwheel) is suitable for valves that are accessed easily and operated infrequently.

- Automated operation (using a pneumatic or electric actuator) is necessary for remote control, frequent operation, or integration into an automated process control system.

Understanding the Trade-offs and Pitfalls

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations and common failure points is key to successful implementation.

The Importance of Correct Installation

A perfectly specified valve can fail due to improper installation. It is essential to follow the manufacturer's instructions for bolt torqueing sequences and values. Uneven stress on the valve body can distort the liner and cause leaks, defeating the purpose of the valve.

Not Ideal for Abrasive Media

The primary strength of PTFE is chemical resistance, not abrasion resistance. For pipelines carrying highly abrasive slurries or solids, the soft PTFE liner can be susceptible to wear and damage over time. In such cases, other valve types may be more appropriate.

Potential for Cold Flow

Under conditions of high, constant pressure (especially at elevated temperatures), PTFE can be susceptible to "cold flow" or creep. This is a slow deformation of the material that can eventually compromise the seal. Ensure the valve's pressure rating is appropriate for your long-term operating conditions.

Making the Right Choice for Your Goal

Your final decision should be guided by the most critical factor for your specific application.

- If your primary focus is handling highly corrosive chemicals: Prioritize verifying the manufacturer's compatibility charts for your specific media, concentration, and temperature.

- If your primary focus is process control and automation: Focus on the actuation package and ensure its specifications, such as cycle speed and failure position, match your plant's control system.

- If your primary focus is reliability in extreme temperatures: Scrutinize the valve's complete temperature and pressure rating curve, as the entire assembly—not just the liner—determines its operational limits.

By methodically matching the valve’s capabilities to your system's demands, you ensure a reliable and long-lasting solution for your most challenging applications.

Summary Table:

| Selection Criteria | Key Considerations |

|---|---|

| Media Compatibility | Verify chemical resistance for specific acids, alkalis, and concentrations. |

| Operating Conditions | Confirm pressure rating (PSI/Bar) and temperature range (-100°C to 260°C). |

| Size & Flow | Match pipe diameter; consider flow rate and pressure drop for on/off or throttling. |

| Actuation Method | Choose manual (lever) for easy access or automated (pneumatic/electric) for control systems. |

Need a PTFE Lined Valve Engineered for Your Demands?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your valve selection is perfectly matched to your application's chemical and physical requirements, from prototype to high-volume production.

Contact our experts today for a consultation on a reliable, long-lasting solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts