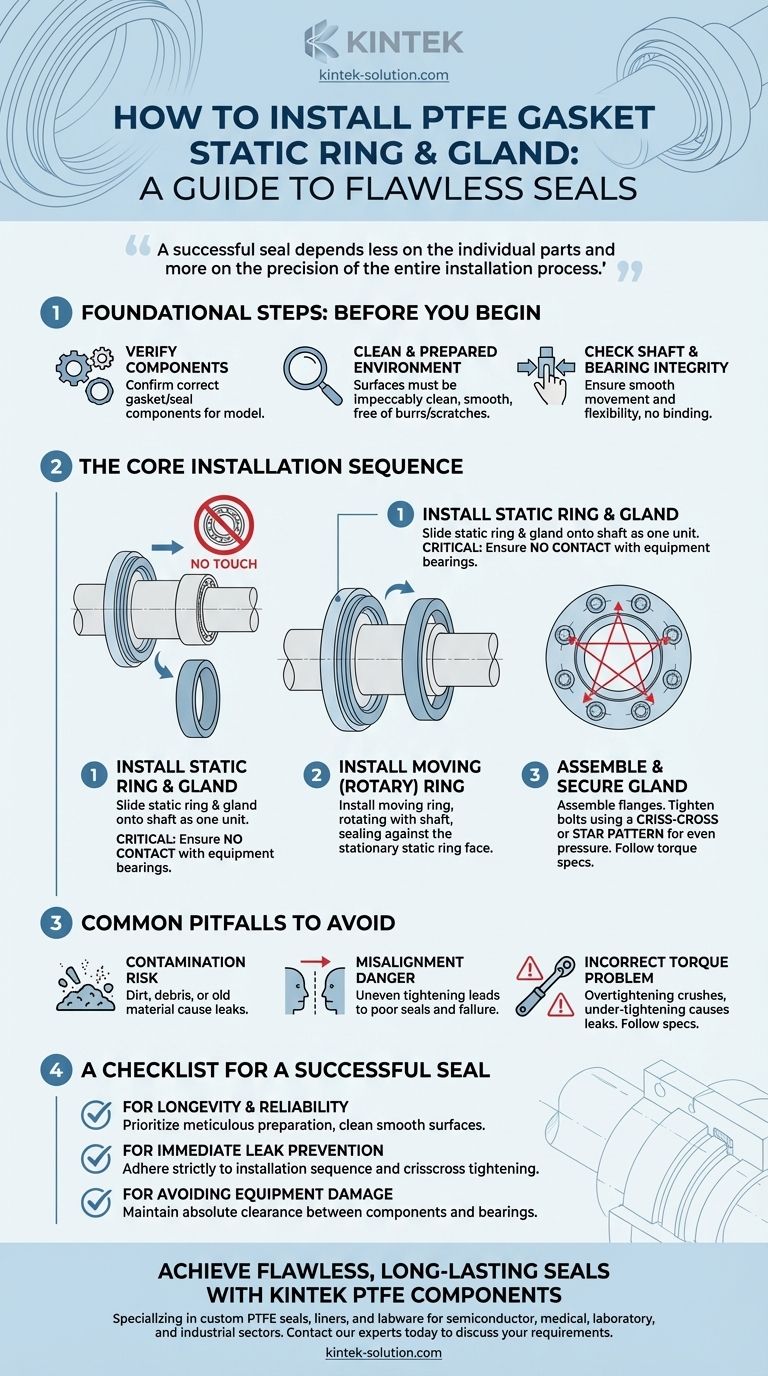

To properly install a PTFE gasket's static ring and gland, you must install them onto the shaft as a single unit. It is critical that these components are seated correctly without touching the equipment's bearings, as this can compromise the seal's integrity and performance. Only after the static ring and gland are in place should you proceed with installing the moving (or rotary) ring.

A successful seal depends less on the individual parts and more on the precision of the entire installation process. Meticulous preparation of the equipment and strict adherence to the correct assembly sequence are the keys to a reliable, leak-free seal.

Foundational Steps: Before You Begin

Proper installation begins long before the components are put in place. Taking the time to prepare the environment is the most critical factor in preventing premature seal failure.

Verify the Correct Components

Before starting, confirm you have the correct gasket and seal components for your specific equipment model. Using the wrong size or material type is a primary cause of sealing issues.

Ensure a Clean and Prepared Environment

The sealing surfaces must be impeccably clean. Inspect the gland and surrounding areas for any burrs, nicks, or scratches that could create a leak path. A smooth, clean surface is non-negotiable for an effective seal.

Check for Shaft and Bearing Integrity

Gently check the equipment's shaft and bearings for flexibility and smooth movement. Any stiffness or binding can put undue stress on the new seal, leading to damage.

The Core Installation Sequence

With the preparation complete, the installation itself is a methodical process. Following this order ensures each component is seated correctly without damaging others.

Step 1: Install the Static Ring and Gland

Slide the static ring and its accompanying gland onto the shaft together as a single assembly. Carefully guide them into position, paying close attention to ensure they do not make contact with the bearings. This clearance is essential.

Step 2: Install the Moving (Rotary) Ring

Once the static components are properly seated, the moving ring can be installed. This part rotates with the shaft and seals against the stationary face of the static ring.

Step 3: Assemble and Secure the Gland

After all seal components are in place, you can assemble the surrounding flanges or housing. When tightening the bolts, always use a crisscross or star pattern. This technique applies even pressure, preventing distortion of the gland and ensuring the seal faces meet squarely.

Common Pitfalls to Avoid

Even with the correct parts, simple mistakes during installation can lead to immediate leaks or a drastically shortened service life.

The Risk of Contamination

Any dirt, debris, or old gasket material left on the flange faces or within the gland can compromise the seal. These contaminants create microscopic pathways for fluid to escape under pressure.

The Danger of Misalignment

If the gland is not tightened evenly, the seal faces will not be parallel. This misalignment creates uneven wear and a poor seal, leading to leaks and eventual failure of the components.

The Problem with Incorrect Torque

Overtightening the gland bolts can crush the PTFE components, while under-tightening will not provide enough force to create an effective seal. Always follow the equipment manufacturer's torque specifications.

A Checklist for a Successful Seal

To ensure a perfect installation, focus on the outcome you need to achieve.

- If your primary focus is longevity and reliability: Prioritize meticulous preparation. Double-check that all surfaces are clean, smooth, and free of burrs before assembly.

- If your primary focus is immediate leak prevention: Adhere strictly to the installation sequence and use a calibrated, crisscross bolt tightening pattern to ensure even pressure.

- If your primary focus is avoiding equipment damage: Maintain absolute clearance between the seal components and the equipment bearings during installation.

A methodical and precise approach transforms a complex task into a guaranteed, high-performance seal.

Summary Table:

| Step | Key Action | Critical Consideration |

|---|---|---|

| 1. Preparation | Verify components and clean all surfaces. | Ensure surfaces are smooth and free of burrs or debris. |

| 2. Install Static Components | Slide static ring and gland onto shaft as one unit. | Do not allow components to touch equipment bearings. |

| 3. Install Moving Ring | Place the rotary ring onto the shaft. | This ring seals against the stationary static ring face. |

| 4. Secure Gland | Tighten bolts in a crisscross/star pattern. | Follow manufacturer's torque specs to avoid distortion. |

Achieve Flawless, Long-Lasting Seals with KINTEK PTFE Components

A perfect seal installation depends on both meticulous technique and high-quality, precision-engineered components. At KINTEK, we specialize in manufacturing custom PTFE seals, liners, and labware for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a reliable prototype or a high-volume order, our commitment to precision production ensures your components will perform flawlessly.

Let us provide the reliable foundation for your next project. Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications