Proper maintenance of a PTFE lined butterfly valve centers on a proactive inspection schedule rather than intensive, frequent intervention. The core activities involve visually checking the liner for wear or damage, monitoring for any external leaks around seals, and ensuring the valve operates smoothly. Because the PTFE lining is inherently durable and corrosion-resistant, the goal is to identify and address potential issues before they compromise the system.

The most effective maintenance strategy is not about constant repair, but about leveraging the valve's low-maintenance design through scheduled, preventative checks. Your primary objective is to protect the integrity of the PTFE liner, as it is the component responsible for the valve's performance and longevity.

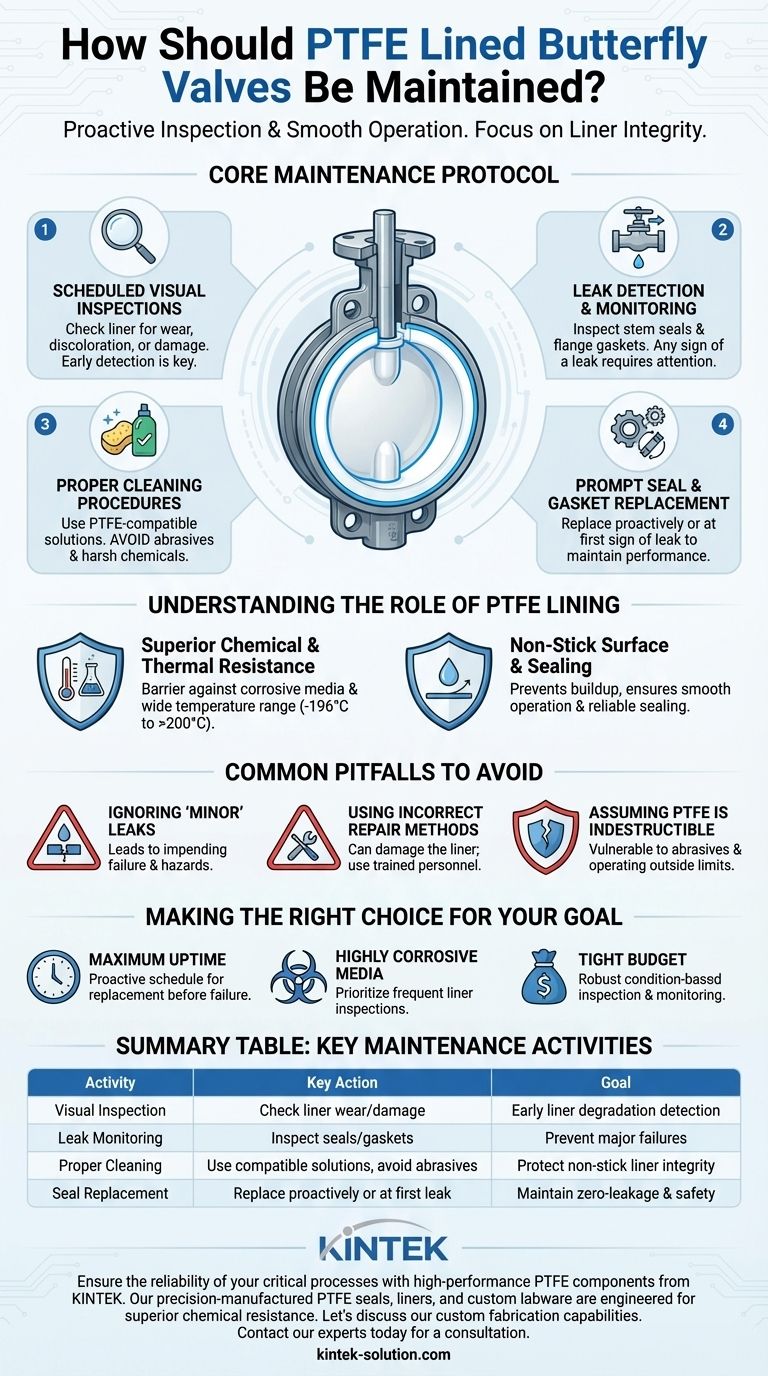

Understanding the Role of the PTFE Lining

To maintain these valves effectively, you must first understand why the PTFE lining is the critical component. The valve's metal body provides structural strength, but the liner performs the most essential functions.

Superior Chemical and Thermal Resistance

The PTFE (polytetrafluoroethylene) lining acts as a complete barrier, isolating the valve's metal body from the process media. This provides exceptional protection against strong acids, alkalis, and other corrosive chemicals.

It also allows the valve to operate across a wide temperature range, from as low as -196°C to over 200°C, without becoming brittle or degrading.

Non-Stick Surface and Sealing

PTFE has an extremely low coefficient of friction and non-stick properties. This prevents media from building up on the valve's internal surfaces, ensuring smooth flow and consistent operation.

This same property allows the disc to create a tight, reliable seal against the liner, often achieving zero-leakage performance when in good condition.

The Core Maintenance Protocol

A simple, consistent protocol is the key to maximizing the lifespan and reliability of your PTFE lined valves.

Scheduled Visual Inspections

The first line of defense is regular visual inspection. Check the visible portions of the liner for any signs of discoloration, peeling, blistering, or mechanical damage. This is the earliest indicator of liner degradation.

Leak Detection and Monitoring

Carefully inspect the areas where the valve stem exits the body and where the valve connects to the piping flanges. Any sign of a leak, no matter how small, indicates that a seal or gasket is beginning to fail and requires attention.

Proper Cleaning Procedures

If cleaning is necessary, use only solutions that are compatible with PTFE. Never use abrasive tools, wire brushes, or harsh chemicals that could scratch, score, or chemically attack the liner. A damaged liner is a failed valve.

Prompt Seal and Gasket Replacement

Seals and gaskets are wear components. They should be replaced as soon as a leak is detected or as part of a preventative maintenance schedule. Allowing a small leak to persist will only lead to more significant and costly failures.

Common Pitfalls to Avoid

Trust in the valve's durability can sometimes lead to complacency. Avoiding these common mistakes is critical for long-term reliability.

Ignoring "Minor" Leaks

A small external weep or drip is a clear signal of an impending failure. This should be addressed immediately, as it will inevitably worsen, potentially leading to a hazardous release and unplanned downtime.

Using Incorrect Repair Methods

Repairs, especially those involving disassembly of the valve, should only be performed by personnel trained on lined valves. Improper handling can easily damage the liner, compromising the entire valve.

Assuming PTFE is Indestructible

While highly resilient, the PTFE liner can be damaged by abrasive slurries or by operating the valve outside of its specified temperature and pressure ratings. Always ensure the valve is correctly specified for the service.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities. Base your approach on the specific demands of your system.

- If your primary focus is maximum uptime and reliability: Implement a proactive schedule for inspecting liners and replacing seals and gaskets before they fail.

- If your primary focus is managing highly corrosive media: Prioritize frequent inspections of the liner's integrity to catch any early signs of chemical attack or permeation.

- If your primary focus is operating within a tight budget: Establish a robust inspection and monitoring program to safely extend component life, replacing parts based on condition rather than a fixed schedule.

Ultimately, consistent and mindful maintenance transforms a reliable component into a guaranteed asset for your process.

Summary Table:

| Maintenance Activity | Key Action | Goal |

|---|---|---|

| Visual Inspection | Check liner for wear, discoloration, or damage. | Early detection of liner degradation. |

| Leak Monitoring | Inspect stem seals and flange gaskets for leaks. | Prevent minor leaks from becoming major failures. |

| Proper Cleaning | Use only PTFE-compatible solutions; avoid abrasives. | Protect the integrity of the non-stick PTFE liner. |

| Seal Replacement | Replace seals/gaskets proactively or at first sign of leak. | Maintain zero-leakage performance and safety. |

Ensure the reliability of your critical processes with high-performance PTFE components from KINTEK.

Our precision-manufactured PTFE seals, liners, and custom labware are engineered for superior chemical resistance and long service life in the most demanding semiconductor, medical, and industrial applications. A proactive maintenance plan starts with components you can trust.

Let's discuss how our custom fabrication capabilities—from prototypes to high-volume orders—can provide the durable, reliable solutions your operation depends on.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability