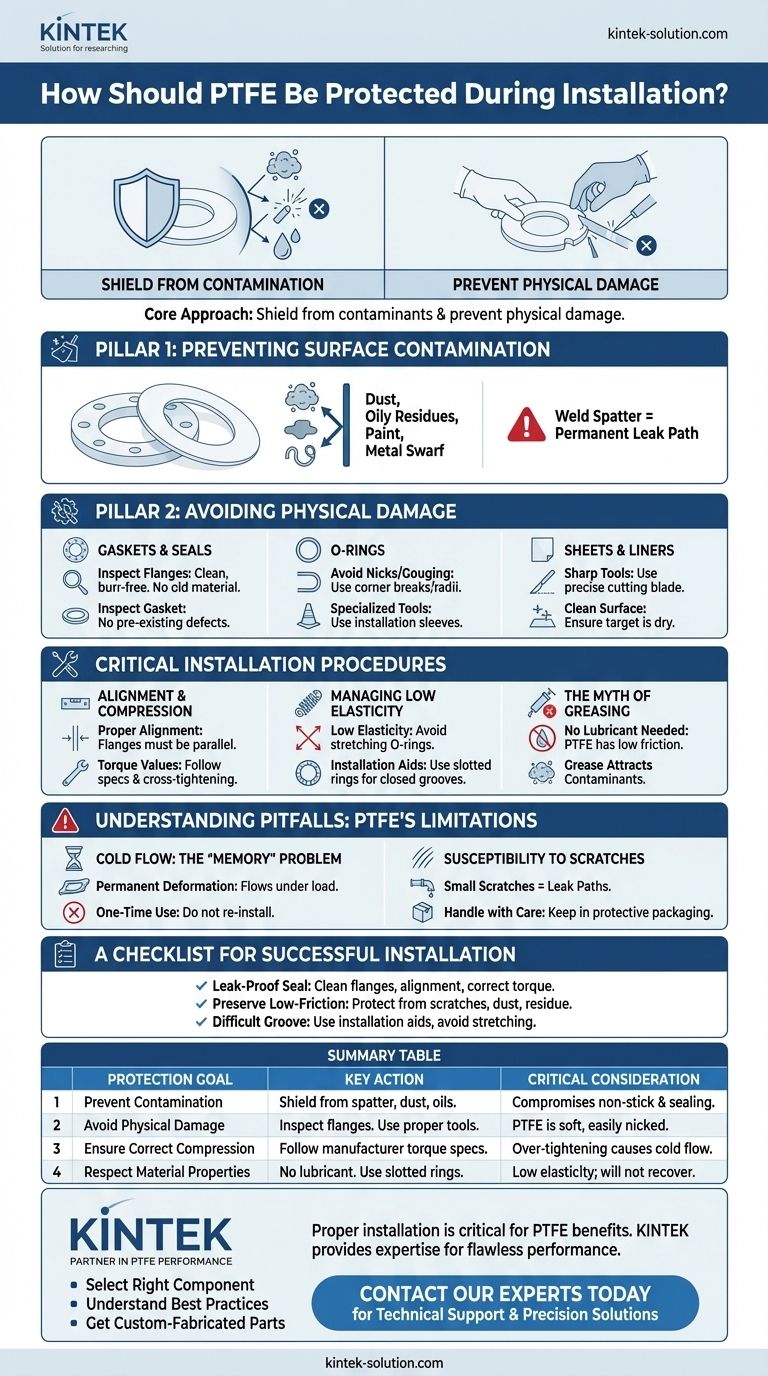

At its core, protecting Polytetrafluoroethylene (PTFE) during installation requires a two-fold approach. You must shield the material from environmental contaminants like weld spatter, paint, and metal swarf while also preventing physical damage such as nicks, scratches, or deformation caused by improper handling, sharp edges, or incorrect compression.

Successful installation is not just about keeping PTFE clean. It's about respecting its unique material properties—specifically, its softness and its tendency to permanently deform under pressure, a characteristic known as "cold flow."

The Two Pillars of PTFE Protection

Proper handling can be broken down into two main areas of focus: preventing contamination of the material surface and avoiding any form of physical damage during the assembly process.

Pillar 1: Preventing Surface Contamination

PTFE's performance, particularly its non-stick and sealing capabilities, relies on a pristine surface.

Contaminants like dust, oily residues, paint spray, and metal swarf can compromise a seal or interfere with its low-friction properties. Before and during installation, the component and the surrounding work area must be kept clean.

For applications near welding or grinding, PTFE components must be adequately shielded. A single piece of weld spatter can create a permanent imperfection that leads to a leak path.

Pillar 2: Avoiding Physical Damage

While chemically robust, PTFE is a relatively soft material that is easily damaged by mechanical force. This is the most common cause of installation failure.

For Gaskets and Seals

Before installation, always inspect the flange or gland surfaces. They must be clean and completely free of burrs, rust, or old gasket material that could damage the new component.

The gasket itself should be inspected for any pre-existing defects. Never install a damaged gasket, as it is guaranteed to cause problems.

For O-Rings

Great care must be taken to avoid nicking or gouging O-rings during assembly. Never stretch or force them over sharp threads or un-chamfered edges.

To prevent this damage, provide corner breaks or radii on the hardware. Alternatively, use specialized installation tools or sleeves to guide the O-ring safely into its groove.

For Sheets and Liners

When cutting PTFE sheets, always use a sharp, precise cutting tool. A dull blade will create rough, uneven edges that can compromise the material's integrity. For self-adhesive sheets, ensure the target surface is clean and dry before application.

Critical Installation Procedures

Protecting PTFE goes beyond simple handling and involves following precise procedures that account for the material's properties.

Alignment and Compression

Proper alignment is non-negotiable for gaskets. Use leveling tools to ensure flanges are parallel. Misalignment concentrates pressure on one side, leading to gasket extrusion and leakage.

Follow the manufacturer's recommended torque values and cross-tightening sequence. Applying too much torque is just as bad as too little; it will crush the PTFE, causing it to deform and extrude from the flange, permanently destroying its sealing ability.

Managing Low Elasticity

Unlike rubber, PTFE has very low elasticity and does not "snap back" well once stretched. Avoid stretching O-rings or other components whenever possible.

For installation in closed grooves, specialized aids or slotted PTFE rings are often used. If using a slotted ring, ensure the slot is oriented to face away from the system pressure.

The Myth of Greasing

PTFE has an extremely low coefficient of friction. No grease or lubricant is needed for installation, and adding it can attract contaminants that interfere with sealing. The material's natural lubricity is sufficient.

Understanding the Pitfalls: PTFE's Unique Limitations

Being aware of PTFE's inherent weaknesses is critical for preventing failure. These are not defects but fundamental properties of the material that must be managed.

Cold Flow: The "Memory" Problem

Under compressive load, PTFE will slowly deform and "flow" to fill imperfections. This is excellent for creating a seal, but the deformation is permanent.

This is why PTFE gaskets and seals are considered one-time use only. Once compressed, they conform to that specific surface and will not seal reliably if re-installed. It's also why over-tightening is so destructive.

Susceptibility to Scratches

A small scratch on a metal part may be insignificant, but on a PTFE seal, it creates a direct leak path. Always handle PTFE components with care, keeping them in their protective packaging until the moment of installation.

A Checklist for Successful Installation

Use this guide to ensure your installation is correct based on your primary objective.

- If your primary focus is a leak-proof seal (gaskets/O-rings): Prioritize clean flange surfaces, precise alignment, and the strict application of correct torque values in a cross-bolting pattern.

- If your primary focus is preserving low-friction properties (sheets/liners): Concentrate on protecting the surface from scratches and ensuring it is free from any dust or chemical residue before and after installation.

- If your primary focus is fitting into a difficult groove (O-rings): Use installation cones or consider specially designed slotted rings to avoid stretching the material, which causes permanent damage.

Proper handling isn't an extra step; it is the fundamental requirement for unlocking the high-performance benefits of PTFE.

Summary Table:

| Protection Goal | Key Action | Critical Consideration |

|---|---|---|

| Prevent Contamination | Shield from weld spatter, dust, and oils. Keep work area clean. | Contaminants compromise non-stick and sealing properties. |

| Avoid Physical Damage | Inspect flanges for burrs. Use proper tools. Avoid stretching. | PTFE is soft and easily nicked or scratched, creating leak paths. |

| Ensure Correct Compression | Follow manufacturer torque specs and cross-tightening sequence. | Over-tightening causes permanent deformation (cold flow). |

| Respect Material Properties | No lubricant needed. Use slotted rings for closed grooves. | PTFE has low elasticity and will not recover from over-stretching. |

Ensure Your PTFE Components Perform Flawlessly

Proper installation is critical to achieving the superior chemical resistance, non-stick properties, and reliable sealing that PTFE is known for. Incorrect handling can lead to premature failure, leaks, and costly downtime.

KINTEK is your partner in PTFE performance. We don't just manufacture high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors—we provide the expertise to ensure they work perfectly in your application.

Let us help you:

- Select the right component for your specific pressure, temperature, and chemical requirements.

- Understand best practices for installation and handling to maximize component life.

- Get custom-fabricated parts designed for easier installation, from prototypes to high-volume orders.

Don't leave performance to chance. Contact our experts today for technical support and precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components