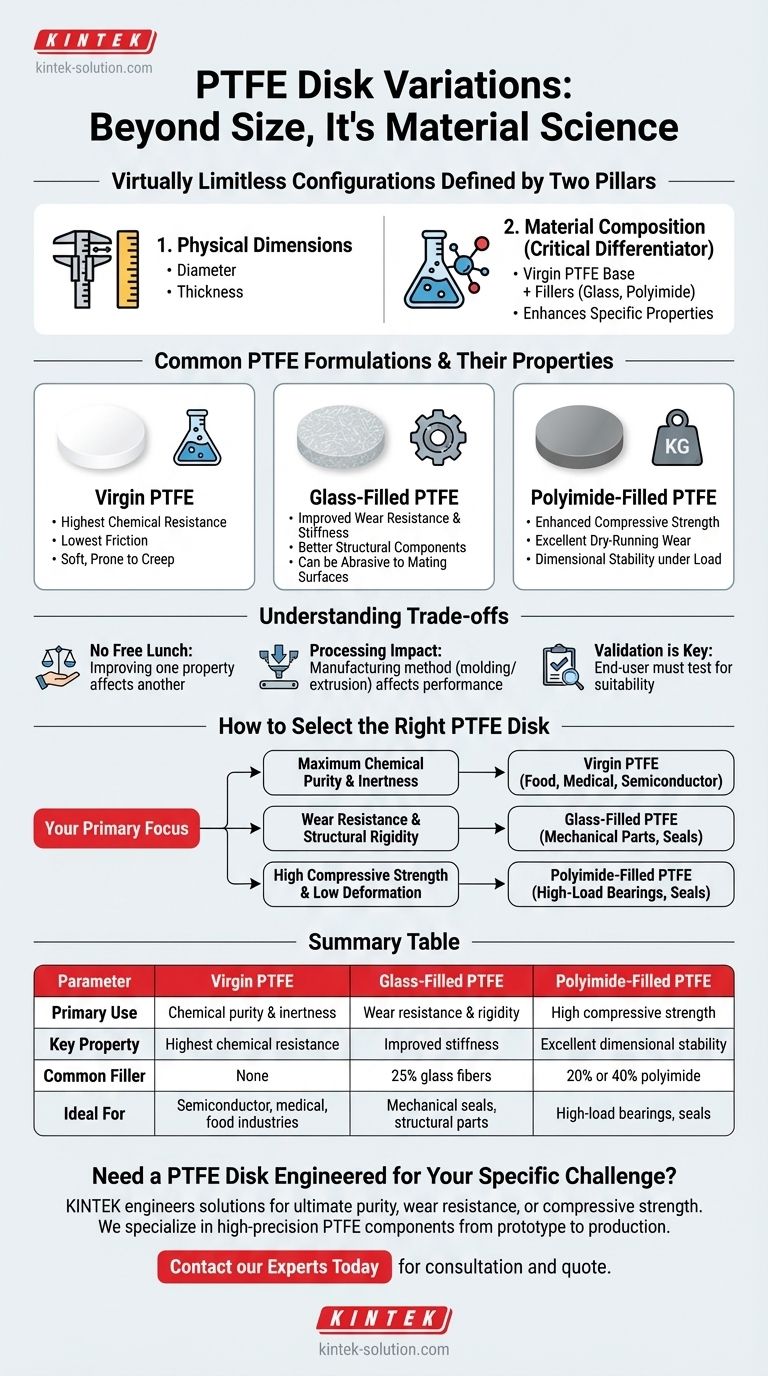

While a single supplier might offer over 200 variations, the number of potential PTFE disk configurations is virtually limitless. These variations are defined by two main categories of parameters: their physical dimensions (like diameter and thickness) and, more critically, their material composition, which involves adding fillers to the base PTFE to enhance specific properties.

The key to understanding PTFE disks is realizing that variation isn't just about size. It's about fundamental changes in material science—using fillers like glass or polyimide to engineer the disk's performance for specific challenges like wear, compression, or chemical exposure.

The Two Pillars of Variation: Dimensions and Composition

The vast array of PTFE disks can be understood by breaking down their differences into two core areas. One is simple geometry, while the other involves the complex chemistry of the material itself.

Physical Dimensions

The most straightforward parameters are the disk's physical measurements. These are dictated by the mechanical requirements of the application, ensuring a proper fit and seal. The primary dimensions are diameter and thickness.

Material Composition (The Critical Differentiator)

This is where the true engineering takes place. Pure, or "virgin," PTFE has remarkable properties but also significant weaknesses. Fillers are added to the PTFE base to create composite materials that overcome these limitations.

A Closer Look at Common PTFE Formulations

The choice of filler fundamentally alters the disk's behavior, making it suitable for a wide range of industrial and scientific uses.

Virgin PTFE

This is pure Polytetrafluoroethylene without any additives. It offers the highest chemical resistance and lowest coefficient of friction. However, it is relatively soft and prone to "creep" or deforming under a sustained load.

Glass-Filled PTFE

By adding glass fibers (a common formulation is 25% glass), the material's wear resistance and stiffness are dramatically improved. This makes it a better choice for structural components, but it can be more abrasive to mating surfaces and may have slightly reduced chemical compatibility.

Polyimide-Filled PTFE

Polyimide is a high-performance polymer added to enhance compressive strength and further improve wear characteristics, especially in dry-running applications. Formulations with 20% or 40% polyimide are common for high-load bearings and seals where dimensional stability is crucial.

Understanding the Trade-offs

Selecting the right PTFE disk requires acknowledging that every enhancement comes with a corresponding compromise. The properties of the final product are also sensitive to how it's made.

The "No Free Lunch" Principle

Adding a filler to improve one property almost always affects another. For example, increasing hardness with glass fibers can reduce the material's flexibility and slightly compromise its inertness in the presence of certain aggressive chemicals.

The Impact of Processing

The final properties of a disk are not determined by the raw material alone. The manufacturing method—such as molding or extrusion—can introduce internal stresses and affect the material's density, influencing its real-world performance.

The Burden of Validation

Because of these complexities, catalogue specifications are only a starting point. It is always the end-user's responsibility to test and fully validate that a specific disk formulation is suitable for their unique application and operating conditions.

How to Select the Right PTFE Disk

Your primary goal will dictate which formulation is the most logical starting point for your evaluation.

- If your primary focus is maximum chemical purity and inertness: Virgin PTFE is the definitive choice for applications in the food, medical, or semiconductor industries.

- If your primary focus is wear resistance and structural rigidity: A glass-filled PTFE provides a significant performance improvement for mechanical parts and seals.

- If your primary focus is high compressive strength and low deformation under load: A polyimide-filled PTFE is engineered specifically for demanding bearing and high-pressure seal applications.

Ultimately, understanding the interplay between material composition and physical dimensions empowers you to specify the precise disk your application demands.

Summary Table:

| Parameter | Virgin PTFE | Glass-Filled PTFE | Polyimide-Filled PTFE |

|---|---|---|---|

| Primary Use | Chemical purity & inertness | Wear resistance & rigidity | High compressive strength |

| Key Property | Highest chemical resistance | Improved stiffness | Excellent dimensional stability |

| Common Filler | None | 25% glass fibers | 20% or 40% polyimide |

| Ideal For | Semiconductor, medical, food industries | Mechanical seals, structural parts | High-load bearings, seals |

Need a PTFE Disk Engineered for Your Specific Challenge?

At KINTEK, we don't just supply PTFE components—we engineer solutions. Whether your priority is ultimate chemical purity in a semiconductor cleanroom, superior wear resistance in industrial machinery, or uncompromising compressive strength for high-load applications, our expertise in custom PTFE fabrication ensures you get the exact performance you need.

We specialize in manufacturing high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. From initial prototypes to high-volume production, we prioritize precision and performance.

Let's discuss your application requirements. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining