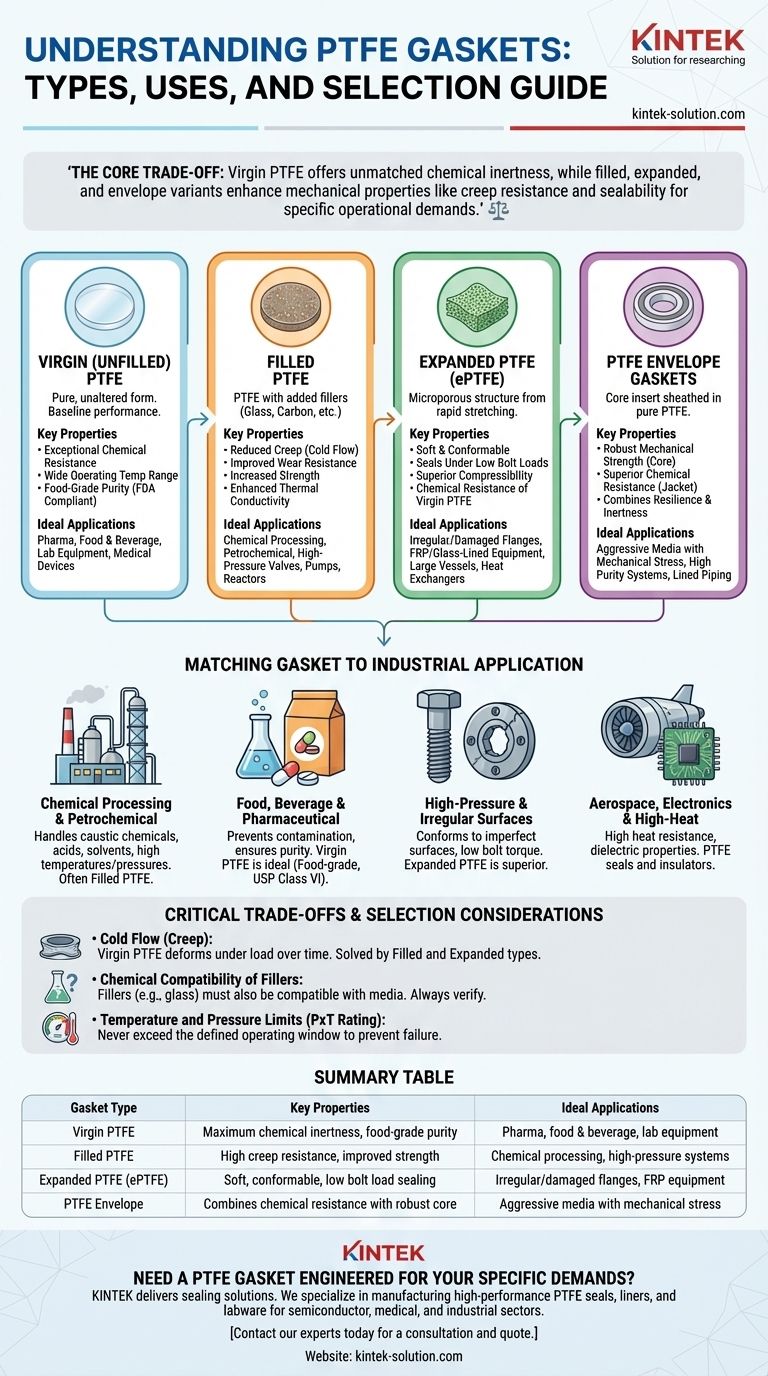

To select the right PTFE gasket, you must look beyond a simple count of types. Instead of a numbered list, it is far more practical to categorize them by their core structure and material composition. The primary types are Virgin (unfilled) PTFE, Filled PTFE, Expanded PTFE (ePTFE), and PTFE Envelope gaskets, each engineered to solve a specific set of industrial challenges.

The choice of a PTFE gasket is not about picking from a list, but about understanding a core trade-off. Virgin PTFE offers unmatched chemical inertness, while filled, expanded, and envelope variants enhance mechanical properties like creep resistance and sealability for specific operational demands.

Understanding the Primary Categories of PTFE Gaskets

Polytetrafluoroethylene (PTFE) is a uniquely versatile material, but its pure form has limitations. The different types of gaskets are designed to leverage its strengths while mitigating its weaknesses for specific environments.

Virgin (Unfilled) PTFE

This is the pure, unaltered form of PTFE. It serves as the baseline for performance.

Its primary strengths are its exceptional chemical resistance, making it inert to most aggressive media, and a wide operating temperature range. It is also a material of choice for food-grade and pharmaceutical applications due to its purity.

Filled PTFE

This category involves adding a filler agent to the virgin PTFE material during manufacturing to improve its mechanical properties.

Fillers are used to reduce PTFE's natural tendency to deform under pressure (a phenomenon known as creep or cold flow). Common fillers include glass, barium sulfate, and carbon, each enhancing properties like wear resistance, stability, and thermal conductivity.

Expanded PTFE (ePTFE)

Expanded PTFE is created by rapidly stretching the material, creating a microporous structure that is incredibly soft and flexible.

This type excels at sealing under low bolt loads and conforming to irregular, damaged, or fragile flange surfaces, such as those on fiberglass reinforced plastic (FRP) or glass-lined equipment. It offers the chemical resistance of virgin PTFE with vastly superior compressibility.

PTFE Envelope Gaskets

This is a composite design, featuring a core insert material (like compressed fiber) sheathed in a "jacket" or "envelope" of pure PTFE.

This construction provides the best of both worlds: the robust mechanical strength and resilience of the insert material combined with the superior chemical resistance of the PTFE outer layer that contacts the media.

Matching Gasket Type to Industrial Application

The distinct properties of each PTFE gasket type make them suitable for a wide range of demanding industries and specific uses.

Chemical Processing and Petrochemical

This is the most common environment for PTFE gaskets. Their ability to handle aggressive media—including caustic chemicals, acids, solvents, and hydrocarbons—is critical. Filled PTFE is often specified here to manage the high pressures and temperatures found in pipes, valves, reactors, and distillation towers.

Food, Beverage, and Pharmaceutical

In these industries, preventing contamination is paramount. Virgin PTFE is the ideal choice due to its inertness and compliance with food-grade standards. It ensures that no gasket material leaches into the product.

High-Pressure and Irregular Surfaces

For applications involving large-diameter vessels, heat exchangers, or delicate flanges, Expanded PTFE (ePTFE) is the superior solution. Its softness allows it to create a tight seal on imperfect surfaces without requiring the high bolt torque that could damage the equipment.

Aerospace, Electronics, and High-Heat

PTFE's excellent heat resistance and dielectric properties make it valuable in specialized applications. It's used for seals and hose linings in high-temperature aerospace systems and serves as an electrical insulator on components like printed circuit boards.

Understanding the Critical Trade-offs

While highly effective, PTFE gaskets are not a universal solution. Understanding their limitations is key to successful implementation.

The Problem of Cold Flow (Creep)

This is the primary weakness of Virgin PTFE. Under the compressive load of a flange, the material can slowly deform or "flow" over time. This leads to a loss of bolt torque, which can compromise the seal and cause leaks. This is the very reason Filled and Expanded PTFE were developed.

Chemical Compatibility of Fillers

While Filled PTFE gaskets are mechanically stronger, the filler material itself may not share PTFE's universal chemical resistance. For example, glass fillers can be attacked by strong alkalis or hydrofluoric acid. It is crucial to verify that both the PTFE and the specific filler are compatible with the process media.

Temperature and Pressure Limits

Every gasket has a defined operating window. Always consult the manufacturer's specifications for the PxT rating, which defines the maximum allowable combination of Pressure (P) and Temperature (T). Exceeding this rating can lead to premature gasket failure.

How to Select the Right PTFE Gasket

Your final choice should be guided by the most critical demand of your specific application.

- If your primary focus is maximum chemical purity and resistance: Choose Virgin PTFE, especially in food-grade, medical, or laboratory applications.

- If your primary focus is handling high pressure and preventing creep: Select a Filled PTFE gasket with a filler material chemically compatible with your media.

- If your primary focus is sealing old, damaged, or fragile flanges: Use Expanded PTFE (ePTFE) for its superior compressibility and sealability under low stress.

- If your primary focus is combining chemical resistance with robust mechanical sealing: Consider a PTFE Envelope gasket, which protects a stronger, more resilient core material.

Ultimately, selecting the correct PTFE gasket depends on a clear analysis of your system's mechanical, thermal, and chemical demands.

Summary Table:

| Gasket Type | Key Properties | Ideal Applications |

|---|---|---|

| Virgin PTFE | Maximum chemical inertness, food-grade purity | Pharma, food & beverage, lab equipment |

| Filled PTFE | High creep resistance, improved strength | Chemical processing, high-pressure systems |

| Expanded PTFE (ePTFE) | Soft, conformable, low bolt load sealing | Irregular/damaged flanges, FRP equipment |

| PTFE Envelope | Combines chemical resistance with robust core | Aggressive media with mechanical stress |

Need a PTFE Gasket Engineered for Your Specific Demands?

At KINTEK, we don't just supply PTFE components—we deliver sealing solutions. Whether you require the absolute chemical purity of Virgin PTFE for pharmaceutical applications, the high-pressure durability of Filled PTFE for chemical processing, the conformability of ePTFE for delicate flanges, or the hybrid strength of a PTFE Envelope gasket, we provide the precise material and custom fabrication you need.

We specialize in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. From rapid prototypes to high-volume production, our focus is on precision and reliability.

Let us help you solve your toughest sealing challenge. Contact our experts today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance