In any heat transfer process, the PTFE sheet is always positioned directly on top of your transfer design and garment. It serves as the final protective layer, sitting between your design and the hot upper platen of the heat press.

The PTFE sheet is not just a cover; it's an essential shield. Its purpose is to protect your equipment from adhesives and inks while protecting your project from direct, scorching heat, ensuring a clean and even transfer.

The Core Function: Why This Barrier is Non-Negotiable

Understanding why the PTFE sheet is used is the key to preventing costly mistakes. It serves two primary, equally important functions.

Protecting Your Heat Press Platen

The upper platen of your heat press is the hot metal surface that applies heat and pressure.

Without a protective barrier, inks from sublimation paper or melted adhesive from heat transfer vinyl (HTV) can easily transfer onto this surface. This residue can then ruin subsequent projects by re-transferring onto them. A non-stick PTFE sheet prevents this contamination entirely.

Shielding Your Garment and Design

Direct contact with a very hot metal platen can damage your project.

The PTFE sheet diffuses the heat, preventing scorching on sensitive fabrics. It also stops the platen from leaving a "shiny" impression on the garment, resulting in a more professional finish.

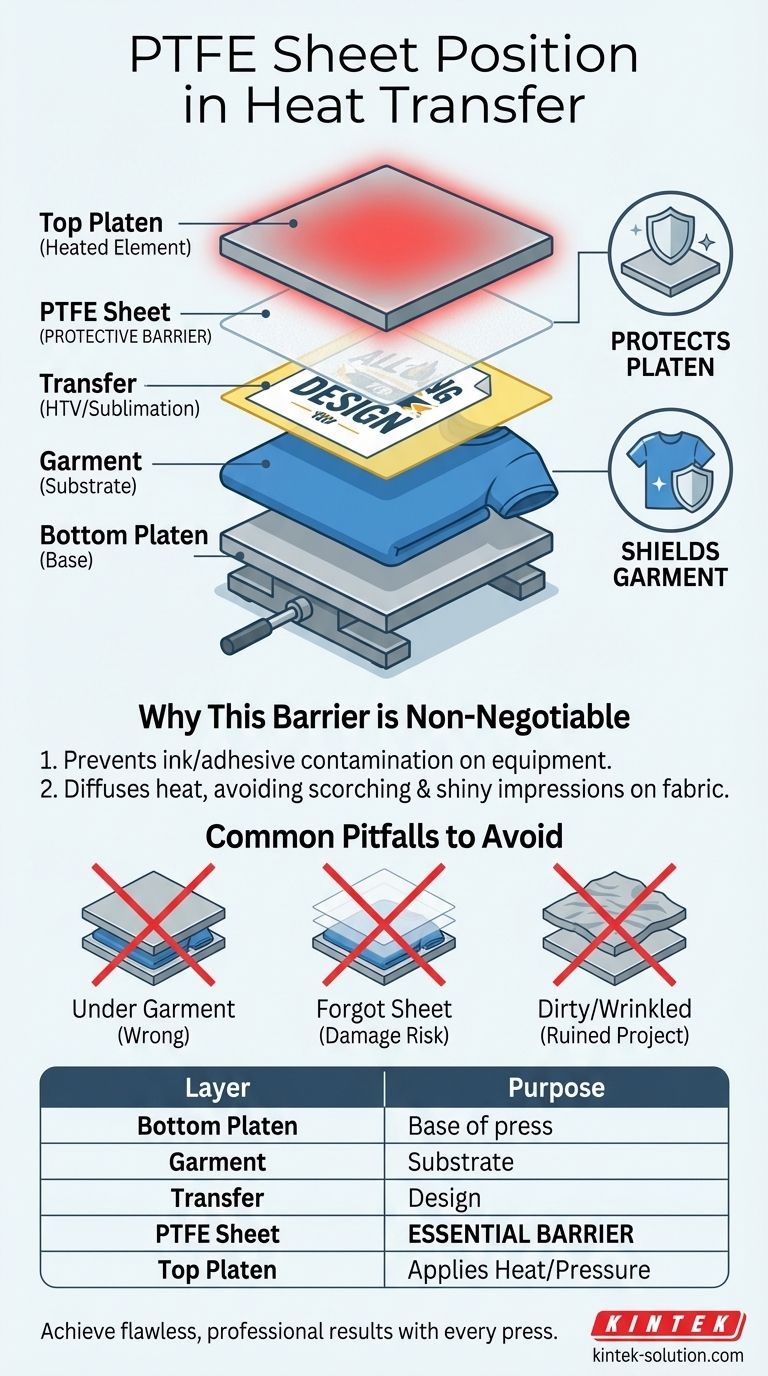

The Correct "Sandwich" for a Perfect Press

The most reliable way to visualize the setup is to think of it as a stack or a "sandwich." From bottom to top, the layers should always be in this order:

- Bottom Platen: The base of your heat press.

- Garment: Your t-shirt, bag, or other substrate, laid flat.

- Transfer: Your HTV or sublimation paper, placed precisely where you want the design.

- PTFE Sheet: The final protective layer covering the transfer and surrounding garment area.

- Top Platen: The heated element you bring down to apply pressure.

Common Pitfalls and Mistakes to Avoid

Correct placement is simple, but incorrect placement can guarantee a failed transfer. Understanding the common errors helps solidify the proper technique.

Mistake: Placing the Sheet Under the Garment

Placing the PTFE sheet underneath your garment serves no purpose. The heat needs to travel through the garment to activate the adhesive on your transfer, and this placement does nothing to protect the top platen.

Mistake: Forgetting the Sheet Entirely

This is the most common and costly error for beginners. Skipping the sheet risks permanently bonding ink or vinyl adhesive to your heat platen, which can be difficult or impossible to clean and will compromise all future work.

Mistake: Using a Dirty or Wrinkled Sheet

The PTFE sheet must be clean and flat. Any wrinkles can be pressed into your garment, and any residue from a previous job (like a stray piece of vinyl or ink) can be accidentally transferred to your new project.

Making the Right Choice for Your Goal

The rule is universal, but its importance varies slightly depending on your transfer method.

- If your primary focus is Heat Transfer Vinyl (HTV): The PTFE sheet protects the clear carrier sheet from melting and shields your fabric from scorching during the press.

- If your primary focus is Sublimation: The PTFE sheet is absolutely critical to prevent ink "blow-out" (where ink turns to gas) from staining and permanently damaging your heat platen.

Properly positioning your PTFE sheet is a simple step that defines a clean, safe, and successful heat transfer every single time.

Summary Table:

| Layer (Bottom to Top) | Purpose |

|---|---|

| Bottom Platen | Base of the heat press. |

| Garment | T-shirt, bag, or other substrate. |

| Transfer | HTV or sublimation paper with your design. |

| PTFE Sheet | Essential protective barrier. |

| Top Platen | Heated element that applies pressure. |

Achieve flawless, professional results with every press. The non-stick, heat-resistant properties of a high-quality PTFE sheet are essential for protecting your equipment and projects.

At KINTEK, we manufacture precision PTFE components, including sheets and custom fabrications, for the textile, industrial, and specialized manufacturing industries. Our products are engineered for durability and consistent performance, from prototypes to high-volume orders.

Protect your investment and elevate your quality. Contact KINTEB today to discuss your PTFE needs and ensure your heat transfer process is always a success.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications