In a laboratory setting, Teflon (PTFE) is primarily used for constructing chemically resistant work surfaces, labware, and equipment components. Its value comes from being almost completely non-reactive, which prevents chemical corrosion and sample contamination.

The core reason Teflon is indispensable in a laboratory is its unique combination of extreme chemical inertness and a low-friction, non-stick surface. This allows scientists to handle highly corrosive materials and ensure the purity of their experiments without interference from the equipment itself.

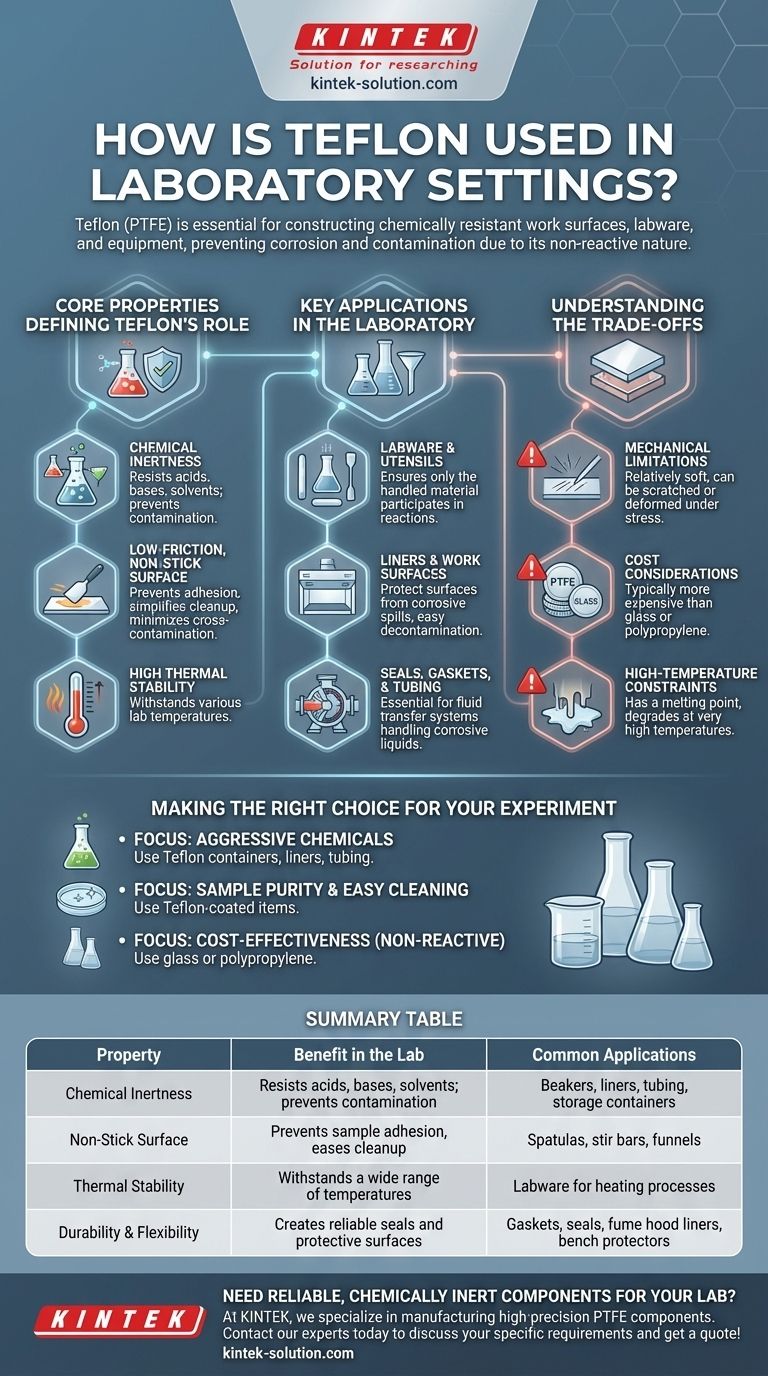

The Core Properties Defining Teflon's Role

To understand why Teflon is so widely used, we must first look at its fundamental material characteristics. These properties directly address the most common challenges faced in a chemical or biological laboratory.

Unmatched Chemical Inertness

Teflon is renowned for its resistance to a vast range of chemicals, including aggressive acids, bases, and organic solvents. This chemical inertness means it will not react with or degrade when exposed to these substances.

This property is critical for maintaining the purity of a sample and the integrity of the lab equipment.

Low-Friction, Non-Stick Surface

The material has an extremely low coefficient of friction, giving it its famous "non-stick" quality. In a lab, this prevents materials from adhering to surfaces.

This is vital for ensuring the complete transfer of substances, simplifying cleanup, and minimizing cross-contamination between different experiments.

High Thermal Stability

Teflon can withstand a wide range of temperatures, making it suitable for various laboratory processes that involve heating.

While it has limits compared to glass or metal, its stability across common experimental temperatures adds to its versatility.

Key Applications in the Laboratory

These core properties translate into several specific and critical applications throughout a modern laboratory environment.

Labware and Utensils

Many common lab items are made from or coated with Teflon. This includes beakers, spatulas, magnetic stir bars, and funnels.

Using Teflon for these items ensures that the material being handled is the only thing participating in the chemical reaction.

Liners and Work Surfaces

Due to its durability and non-reactive nature, Teflon is used to line fume hoods, chemical storage containers, and pipes.

It also serves as a protective sheet for benchtops, shielding the underlying surface from corrosive spills and making decontamination simple.

Seals, Gaskets, and Tubing

Within laboratory equipment, Teflon is a primary material for seals, gaskets, and tubing. Its chemical resistance is essential for fluid transfer systems that handle corrosive liquids.

Its flexibility and low-friction nature make it ideal for creating tight, durable seals in pumps and connection points.

Understanding the Trade-offs

While incredibly useful, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Limitations

Teflon is a relatively soft material. It can be scratched or deformed under high physical stress or abrasion.

For applications requiring significant structural rigidity or hardness, materials like glass or stainless steel are often superior.

Cost Considerations

Lab equipment made from solid Teflon is typically more expensive than its counterparts made from glass or other plastics like polypropylene.

The decision to use Teflon often comes down to a trade-off between its higher upfront cost and its superior performance with reactive chemicals.

High-Temperature Constraints

While thermally stable, Teflon has a definitive melting point and can begin to degrade at very high temperatures.

For experiments requiring extreme heat, such as those performed in a furnace, materials like ceramics, quartz, or specialty metal alloys are necessary.

Making the Right Choice for Your Experiment

Selecting the correct material is fundamental to successful and repeatable science. Your choice should always be guided by the specific demands of your procedure.

- If your primary focus is handling aggressive acids or solvents: Use Teflon containers, liners, and tubing to guarantee material integrity and prevent sample contamination.

- If your primary focus is preventing sample loss and cross-contamination: Use Teflon-coated stir bars, spatulas, and beakers for their non-stick properties, ensuring complete transfer and easy cleaning.

- If your primary focus is cost-effectiveness with non-reactive substances: Standard laboratory glass or polypropylene may be the more practical and economical choice.

Ultimately, understanding the distinct properties of Teflon empowers you to design more robust experiments and generate more reliable data.

Summary Table:

| Property | Benefit in the Lab | Common Applications |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents; prevents contamination | Beakers, liners, tubing, storage containers |

| Non-Stick Surface | Prevents sample adhesion, eases cleanup | Spatulas, stir bars, funnels |

| Thermal Stability | Withstands a wide range of temperatures | Labware for heating processes |

| Durability & Flexibility | Creates reliable seals and protective surfaces | Gaskets, seals, fume hood liners, bench protectors |

Need reliable, chemically inert components for your lab?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom fabrications—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment maintains purity and performance, from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What customization options are available for PTFE-lined bottle caps? Tailor Caps for Chemical & Temperature Resistance

- What are the main materials used for septa in laboratory settings? PTFE vs. Silicone Explained

- What are the applications of PTFE-lined bottle caps? Ensure Ultimate Purity and Chemical Resistance

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- What are the advantages of PTFE in pharmaceutical and biotech research? Ensure Purity and Prevent Contamination

- What are the benefits of silicone/PTFE liners? Ensure Unmatched Sample Purity and Integrity

- What are the temperature ranges for PTFE-lined bottle caps? From -200°C to +250°C for Your Critical Applications

- What are the primary applications of PTFE syringe filters in laboratories? Ensure Sample Purity & Protect Sensitive Instruments