PTFE (Polytetrafluoroethylene) plays a critical role in enhancing the performance and safety of football protective gear. Its unique properties—low friction, chemical resistance, and waterproofing—make it ideal for helmets, pads, gloves, and apparel. By reducing skin irritation, improving comfort, and maintaining durability under stress, PTFE helps athletes perform at their best while minimizing injury risks. Below, we explore how PTFE is integrated into football gear and why it’s a preferred material for manufacturers.

Key Points Explained:

-

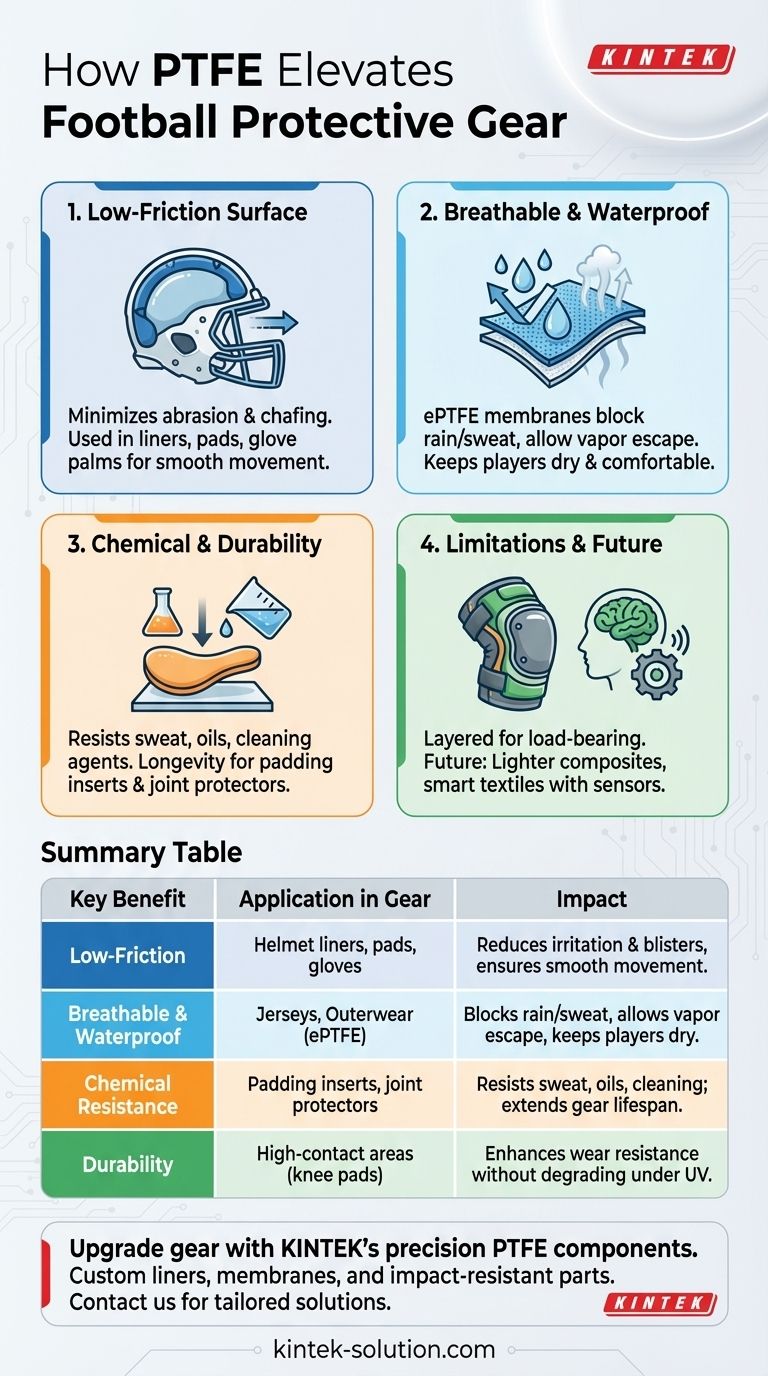

Low-Friction Surface for Reduced Abrasion

- PTFE’s slippery surface minimizes friction between gear and skin, preventing chafing and blisters during prolonged use.

- Applied to helmet liners, pad interiors, and glove palms to ensure smooth movement without irritation.

- Example: In gloves, PTFE coatings enhance grip while reducing wear on players’ hands during tackles or ball handling.

-

Breathable and Waterproof Membranes in Apparel

- PTFE membranes (e.g., expanded PTFE or ePTFE) are laminated into jerseys and outerwear to block rain/sweat while allowing moisture vapor to escape.

- This keeps players dry and comfortable in wet or humid conditions, maintaining optimal body temperature.

- Unlike traditional waterproof materials, PTFE avoids the "sticky" feel, improving mobility.

-

Chemical and Durability Advantages

- PTFE resists sweat, oils, and cleaning agents, ensuring gear longevity despite frequent washing or harsh field conditions.

- Used in custom PTFE parts like padding inserts or joint protectors, where tailored shapes are needed for impact absorption.

- Unlike rubber or foam, PTFE doesn’t degrade when exposed to UV light or disinfectants.

-

Limitations and Mitigations in Football Gear

- PTFE’s low tensile strength limits its use in load-bearing components (e.g., helmet shells). Instead, it’s layered with stronger materials like polycarbonate.

- To address wear sensitivity, PTFE is often blended with fillers (e.g., carbon or glass fibers) in high-contact areas like knee pads.

- Note: Its inability to be welded means seams in apparel rely on adhesives or stitching.

-

Future Innovations

- Research explores PTFE composites with graphene or ceramics for lighter, more abrasion-resistant gear.

- Potential for smart textiles: Integrating PTFE membranes with sensors to monitor player hydration or impact forces.

PTFE’s versatility quietly elevates football gear—balancing protection, comfort, and durability. Whether in off-the-shelf equipment or specialized custom PTFE parts, its science-driven design helps athletes focus on the game, not their gear.

Summary Table:

| Key Benefit | Application in Football Gear | Impact |

|---|---|---|

| Low-Friction Surface | Used in helmet liners, pad interiors, and glove palms | Reduces skin irritation and blisters, ensuring smooth movement |

| Breathable & Waterproof | Laminated into jerseys and outerwear as ePTFE membranes | Blocks rain/sweat while allowing moisture vapor to escape, keeping players dry |

| Chemical Resistance | Applied in padding inserts and joint protectors | Resists sweat, oils, and cleaning agents, extending gear lifespan |

| Durability | Blended with fillers (e.g., carbon fibers) in high-contact areas like knee pads | Enhances wear resistance without degrading under UV or disinfectants |

Upgrade your football gear with PTFE’s advanced protection and comfort! KINTEK specializes in precision-engineered PTFE components for sports equipment, including custom liners, membranes, and impact-resistant parts. Whether you're a manufacturer or team looking for tailored solutions, contact us today to discuss how our PTFE innovations can elevate your gear’s performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are lined pipes and how do they work? Achieve Superior Chemical Resistance at a Lower Cost

- What is a Teflon sheet used for in heat press applications? The Essential Non-Stick Barrier

- What are the temperature limits for PTFE packing performance? Withstand -200°C to 260°C for Reliable Sealing

- How are PTFE seals used in medical device and life sciences applications? Essential for Sterility & Precision

- What types of PTFE tri clamp gaskets are available? Choose the Right Seal for Your System

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency

- What industries commonly use expanded PTFE gaskets? A Guide to Critical Sealing Solutions

- What makes Teflon sheets resistant to chemicals? The Power of a Molecular Fortress