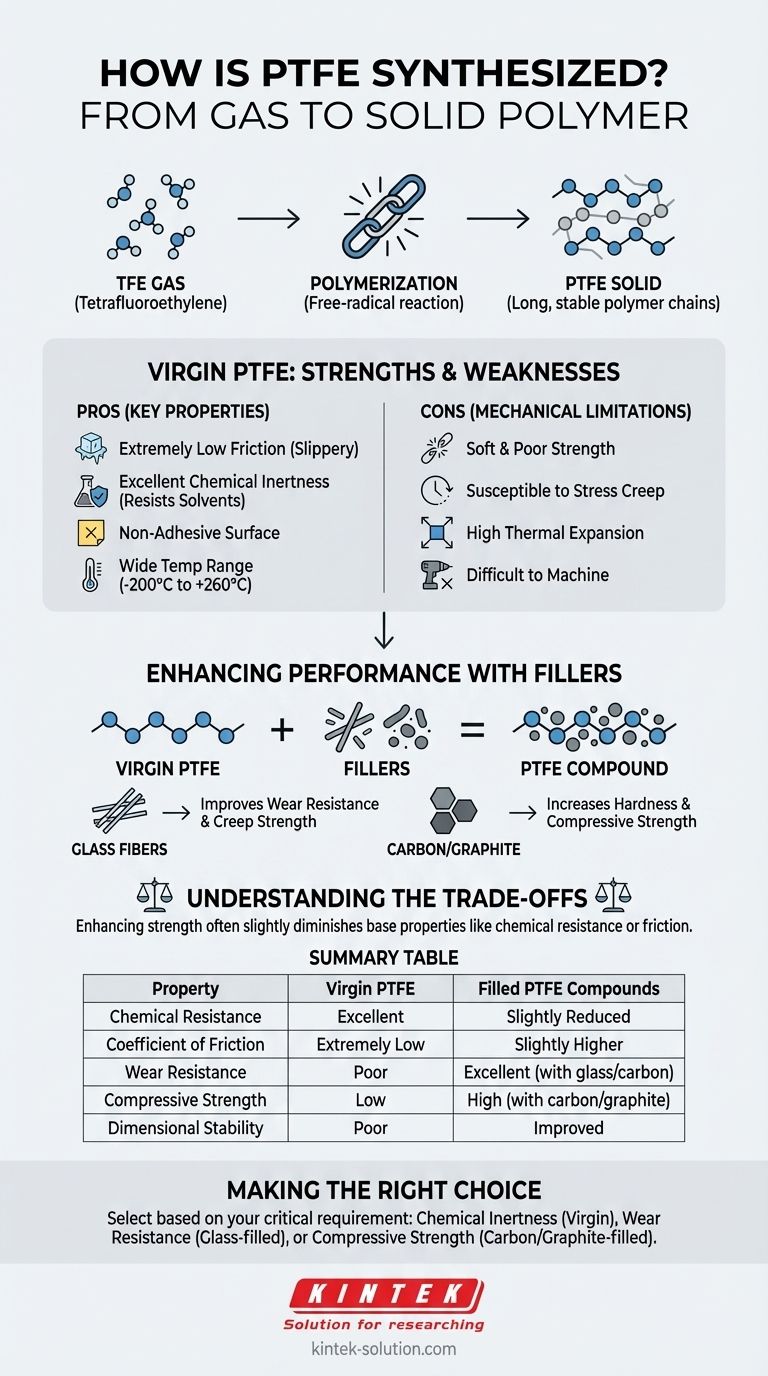

At its core, Polytetrafluoroethylene (PTFE) is produced through the polymerization of tetrafluoroethylene (TFE) gas. This chemical process uses a free-radical reaction to link individual TFE gas molecules into the long, stable polymer chains that give the material its exceptional and well-known properties.

The synthesis of PTFE creates a polymer with remarkable chemical resistance and an extremely low coefficient of friction. However, this same process results in a soft material with poor mechanical strength, making filled compounds essential for most demanding structural applications.

The Foundation: From Gas to Solid Polymer

The synthesis process is fundamental to understanding both the strengths and weaknesses of PTFE. The unique molecular structure created during polymerization dictates how the material behaves in the real world.

The Polymerization Process

The creation of PTFE involves linking, or polymerizing, single units of tetrafluoroethylene (TFE) gas. This reaction forms extremely long and stable molecular chains, which constitute the solid material we recognize as PTFE.

Resulting Molecular Structure

This process results in a simple, repeating structure of carbon and fluorine atoms. The carbon-fluorine bond is exceptionally strong, which is the source of PTFE's renowned chemical inertness and thermal stability.

Key Properties of Virgin PTFE

The direct result of this synthesis is a material, often called "virgin grade" PTFE, with a unique combination of characteristics:

- A very low coefficient of friction, making it one of the slipperiest solids known.

- Excellent chemical inertness, resisting nearly all industrial chemicals and solvents.

- A non-adhesive surface that materials do not readily stick to.

- A wide functional temperature range, from –200°C to +260°C.

- Excellent dielectric properties, making it a superb electrical insulator.

Why Virgin PTFE Is Often Not Enough

While the properties of virgin PTFE are impressive, its molecular structure also creates significant mechanical limitations that must be understood for successful application design.

Inherent Mechanical Weaknesses

The primary drawbacks of pure, unfilled PTFE are its softness and poor mechanical strength. The material is susceptible to stress creep, or deformation over time when under a constant load.

The Challenge of Dimensional Stability

PTFE also has a high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes, making it very difficult to machine to tight tolerances without careful process control.

Enhancing Performance with Fillers

To overcome the inherent weaknesses of the base polymer, PTFE is frequently blended with various fillers to create what are known as PTFE compounds.

What are PTFE Compounds?

PTFE compounds are blends of the base polymer with inorganic or organic materials. Adding these fillers is a standard industry practice to improve specific mechanical properties and tailor the material for a given application.

Common Fillers and Their Impact

Different fillers are chosen to target specific performance improvements.

- Glass Fibers: Adding 15% to 25% glass fiber is common. This drastically improves wear resistance, enhances creep strength, and reduces deformation under load.

- Carbon and Graphite: These fillers are used to increase hardness, improve compressive strength, and enhance abrasion resistance.

Understanding the Trade-offs

Selecting a filled PTFE compound is an engineering decision that involves balancing competing properties. Enhancing one characteristic may slightly diminish another.

Sacrificing Some Benefits for Strength

Adding fillers makes the material mechanically robust, but it can slightly alter the base properties. For example, a glass-filled compound may have a slightly higher coefficient of friction or marginally reduced chemical resistance compared to virgin PTFE.

Critical Machining Considerations

Whether virgin or filled, PTFE's nature demands specific manufacturing practices. Its softness and thermal properties require:

- Extremely sharp and polished cutting tools, such as HSS or carbide.

- Moderate cutting speeds to prevent heat buildup and material expansion.

- Careful clamping pressure to avoid compressing or deforming the part during machining.

Making the Right Choice for Your Application

Your final material selection must be driven by the most critical performance requirement for your specific goal.

- If your primary focus is maximum chemical inertness or the lowest possible friction: Virgin (unfilled) PTFE is the superior choice, provided the mechanical demands are low.

- If your primary focus is wear resistance and part stability under load: A glass-filled PTFE compound offers a significant and necessary improvement over the virgin grade.

- If your primary focus is high compressive strength or hardness: A carbon or graphite-filled PTFE compound is engineered for these more demanding structural roles.

Understanding that PTFE's synthesis creates both its incredible advantages and its inherent flaws is the first step toward strategically selecting the right grade for your specific engineering challenge.

Summary Table:

| Property | Virgin PTFE | Filled PTFE Compounds |

|---|---|---|

| Chemical Resistance | Excellent | Slightly Reduced |

| Coefficient of Friction | Extremely Low | Slightly Higher |

| Wear Resistance | Poor | Excellent (with glass/carbon) |

| Compressive Strength | Low | High (with carbon/graphite) |

| Dimensional Stability | Poor (High thermal expansion) | Improved |

| Primary Use Case | Non-structural, chemical exposure | Structural, mechanical load |

Need a PTFE component engineered for your specific challenge?

KINTEK specializes in manufacturing precision PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the pure chemical resistance of virgin PTFE or the enhanced mechanical strength of a filled compound, our expertise in custom fabrication from prototypes to high-volume orders ensures you get the right material and the perfect part.

Contact us today to discuss your application and get a quote!

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- Is the PTFE bottle suitable for ultra-pure applications? Ensure Absolute Sample Integrity

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications