In the food industry, Polytetrafluoroethylene (PTFE) packing is a critical sealing component used in equipment like pumps, valves, and mixers. Its primary function is to create a secure seal that prevents leaks, stops external contaminants from entering the product stream, and ensures the food itself remains pure and unadulterated.

PTFE packing is not just a mechanical seal; it is an essential food safety barrier. Its unique combination of chemical inertness, non-stick properties, and temperature resistance makes it the default choice for protecting food purity and ensuring operational reliability.

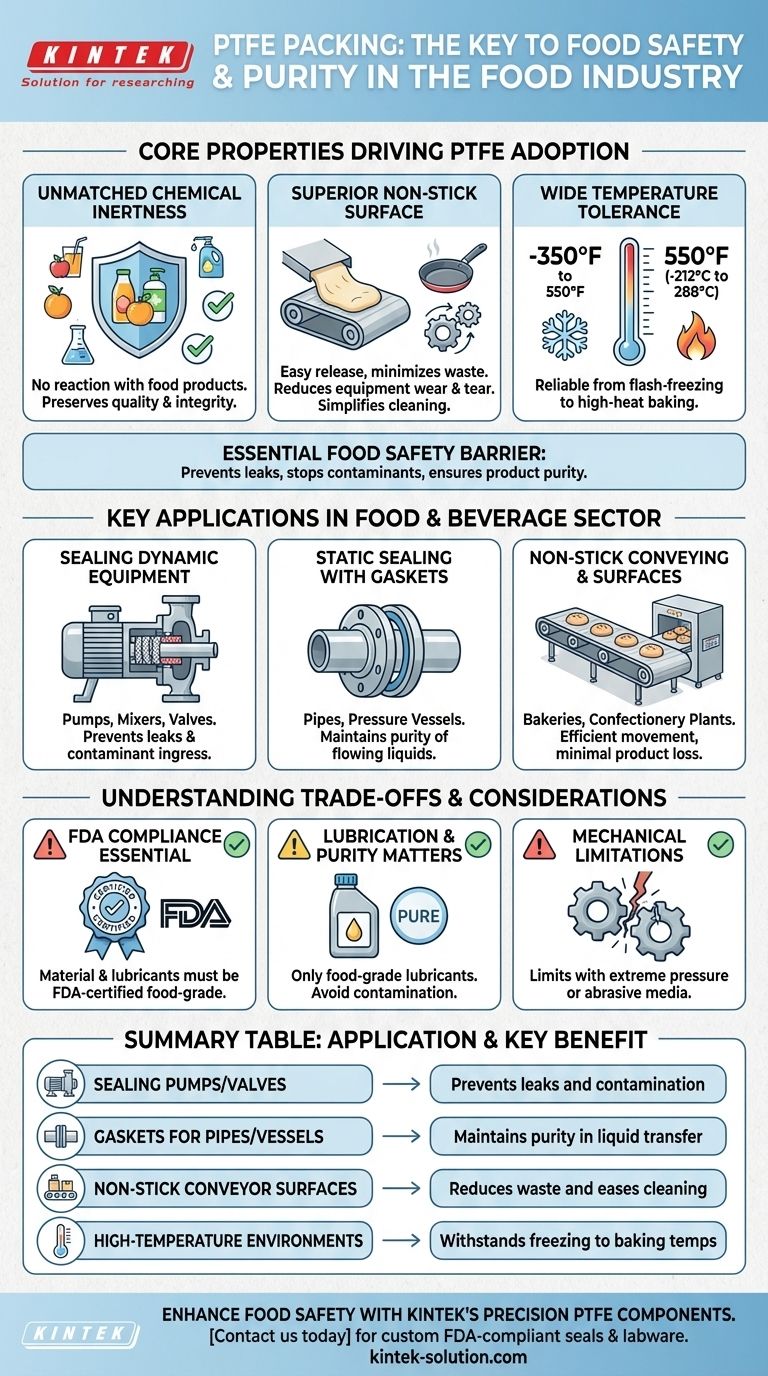

The Core Properties Driving PTFE Adoption

The widespread use of PTFE in food processing is not accidental. It stems from a specific set of material properties that directly address the industry's stringent demands for safety and efficiency.

Unmatched Chemical Inertness

PTFE is prized for being chemically inert, meaning it does not react with the substances it contacts. This is vital when handling a wide range of food products, from acidic fruit juices to alkaline cleaning solutions.

This inertness ensures the packing material itself does not contaminate the product or degrade over time, preserving both food quality and the integrity of the seal.

Superior Non-Stick Surface

The famous non-stick quality of PTFE provides significant operational advantages. In mixers and on conveyor belts, it ensures an easy release of products like dough and confectionery, which minimizes waste.

This low-friction surface also reduces wear and tear on rotating shafts in pumps and mixers, extending the life of the equipment. Furthermore, it simplifies cleaning processes, as food residue does not adhere to the packing.

Wide Temperature Tolerance

PTFE operates reliably across an exceptionally broad temperature range, typically from -350°F to 550°F (-212°C to 288°C).

This makes it suitable for nearly any food processing environment, from flash-freezing applications to high-temperature baking and cooking, without losing its structural integrity or sealing capability.

Key Applications in the Food & Beverage Sector

These core properties translate into several critical applications where maintaining a pure and contained environment is non-negotiable.

Sealing Dynamic Equipment

The most common use of PTFE packing is in dynamic applications like pumps, mixers, and valves. The braided packing is installed in a stuffing box to create a seal around a rotating shaft or moving stem.

Here, it performs two jobs: preventing the food product from leaking out and stopping external contaminants like lubricants or airborne particles from getting in.

Static Sealing with Gaskets

In static applications, PTFE is formed into gaskets used to seal connections between pipes, pressure vessels, and other equipment.

This is especially common in the dairy and beverage industries, where the purity of liquids flowing through the system is paramount. PTFE envelope gaskets provide a pure contact surface backed by a more resilient core material.

Non-Stick Surfaces and Conveying

Beyond traditional seals, PTFE's properties are leveraged for food-contact surfaces. PTFE-coated sheets and transport belts are used extensively in bakeries and confectionery plants.

The material's heat resistance and non-stick nature are ideal for moving products through ovens and cooling tunnels efficiently and with minimal product loss.

Understanding the Trade-offs and Considerations

While PTFE is a highly effective material, selecting and implementing it correctly requires an understanding of its practical limitations and regulatory context.

The Importance of FDA Compliance

Not all PTFE is created equal. For food applications, the material must meet specific regulatory standards, such as those set by the FDA.

PTFE can be combined with other materials or lubricants to enhance its properties. It is critical to ensure that all components of the packing assembly are certified as food-grade and safe for direct or incidental contact.

Lubrication and Purity

Many braided packing styles incorporate a lubricant to reduce friction and improve sealing during break-in. In a food context, this lubricant must be food-grade.

Using a non-compliant lubricant would completely negate the benefits of using an inert PTFE polymer, introducing a potential source of contamination.

Mechanical Limitations

PTFE is a polymer, not a metal. While durable, it has limits regarding extreme pressure or when sealing highly abrasive media, such as slurries containing hard solids. In these specialized cases, a different packing configuration or material may be required to prevent premature wear.

Making the Right Choice for Your Application

Selecting the correct PTFE packing solution depends on your primary operational goal.

- If your primary focus is product purity and safety: Choose a packing that is explicitly certified as FDA-compliant and ensure any lubricants used are also certified as food-grade.

- If your primary focus is operational efficiency: Leverage PTFE's non-stick properties to reduce cleaning time and its low-friction nature to minimize wear on equipment shafts.

- If your primary focus is handling aggressive or high-temperature products: Verify that the specific grade of PTFE packing meets the temperature and chemical resistance requirements for your process, from acidic juices to hot oils.

By understanding these principles, you can confidently specify PTFE packing to enhance both the safety and efficiency of your food processing operations.

Summary Table:

| Application | Key Benefit |

|---|---|

| Sealing Pumps/Valves | Prevents leaks and contamination |

| Gaskets for Pipes/Vessels | Maintains purity in liquid transfer |

| Non-Stick Conveyor Surfaces | Reduces waste and eases cleaning |

| High-Temperature Environments | Withstands freezing to baking temps |

Enhance your food processing safety and efficiency with KINTEK's precision PTFE components.

We specialize in custom fabricating FDA-compliant PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, our focus on precision ensures your equipment operates reliably while meeting strict purity standards.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In what industries are PTFE instrumentation tube fittings commonly used? Ensuring Purity and Chemical Resistance

- Why is CNC machining the preferred method for manufacturing Teflon parts? Achieve Precision Without Compromise

- How are PTFE coatings used in the aerospace industry? Ensuring Reliability in Extreme Conditions

- What are PTFE expansion joints and what is their primary function? Protect Your Piping System from Stress and Failure

- What are the main components constructed from PTFE in these valves? Ensure Ultimate Purity and Chemical Resistance

- What are the key advantages of PTFE lip seals? Superior Performance in Extreme Conditions

- What makes PTFE washers suitable for electrical applications? Achieve Superior Insulation and Reliability

- What material is used to make PTFE bushings? The Ultimate Guide to PTFE's Performance