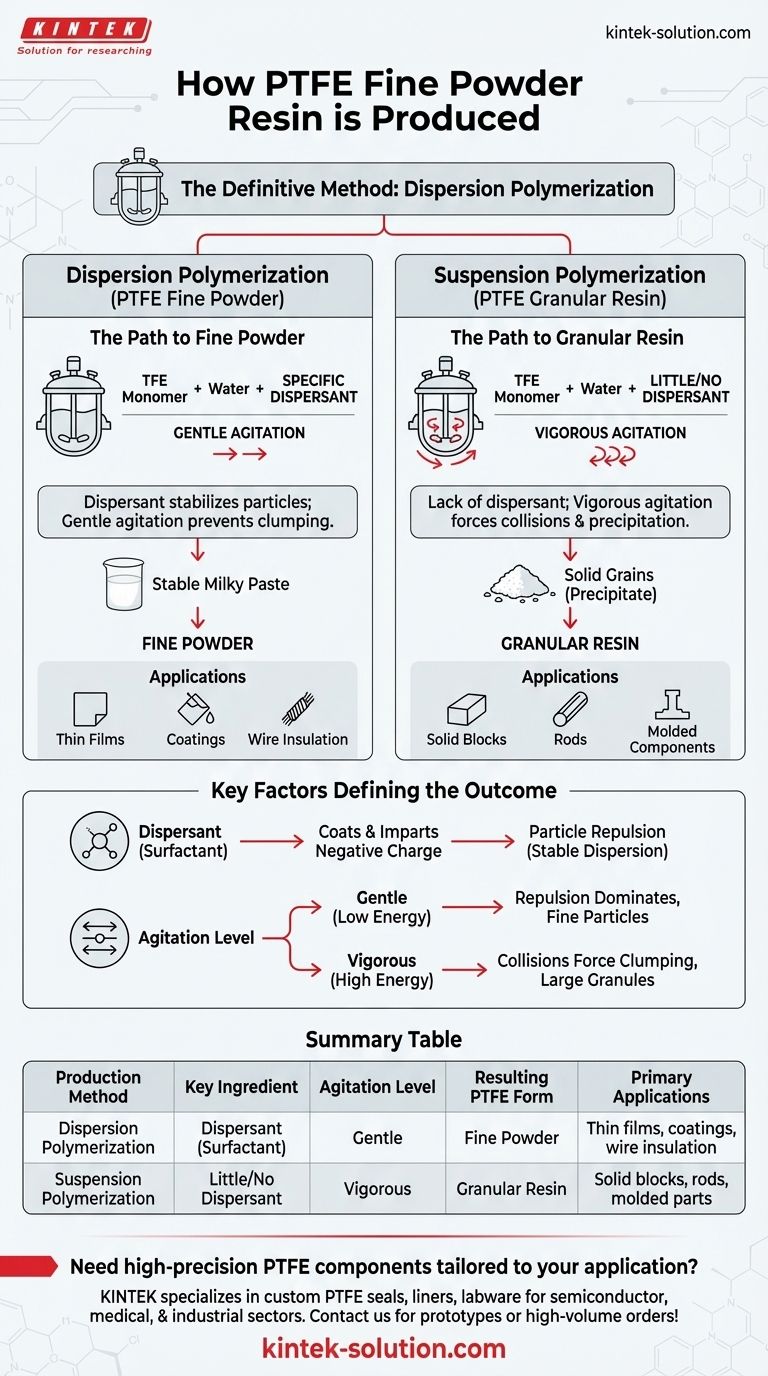

The definitive method for producing Polytetrafluoroethylene (PTFE) fine powder is a process known as dispersion polymerization. This technique involves polymerizing Tetrafluoroethylene (TFE) monomer in water with a specific type and amount of dispersant, combined with gentle agitation. The result is a stable aqueous dispersion of tiny, negatively charged colloidal particles, which is then processed into the final fine powder.

The fundamental difference between producing PTFE fine powder versus granular resin lies in two key process variables: the presence of a dispersant and the intensity of agitation. Gentle stirring with a dispersant creates the milky paste needed for fine powder, while vigorous stirring without one creates solid grains.

The Two Core Methods of PTFE Production

Understanding how fine powder is made requires contrasting it with the alternative method for producing granular PTFE. The choice of polymerization technique directly dictates the final physical form and application of the material.

Dispersion Polymerization: The Path to Fine Powder

Dispersion polymerization is the required method for creating PTFE fine powder. In this process, the TFE monomer is polymerized in water.

A crucial ingredient, a dispersant (a type of surfactant), is added to the mixture. This chemical stabilizes the newly formed PTFE particles.

The entire reaction is subjected to only gentle agitation. This prevents the small particles from clumping together, resulting in a stable, milky paste of colloidal particles, which can then be processed into a very fine powder.

Suspension Polymerization: The Path to Granular Resin

In contrast, suspension polymerization is used to create PTFE granular resin, which is better suited for molding.

In this method, little or no dispersant is used. Instead of gentle stirring, the reaction mixture is agitated vigorously.

This combination of factors forces the polymer particles to collide and merge, causing them to precipitate out of the water as larger, solid grains. These grains can then be easily processed into pellets for molding applications.

Key Factors That Define the Outcome

The final form of the PTFE—either a fine powder or a coarse granule—is not accidental. It is the direct result of controlling specific chemical and physical forces during polymerization.

The Critical Role of the Dispersant

The dispersant acts as a stabilizing agent. It coats the surfaces of the tiny, newly-formed PTFE particles.

This coating imparts a negative electrical charge to each particle. Since like charges repel, the particles push each other away, preventing them from coagulating into larger clumps and keeping them suspended in the water.

The Decisive Impact of Agitation

The level of mechanical agitation determines whether the dispersant can do its job effectively.

Gentle agitation is low-energy and allows the dispersant's repulsive forces to dominate, maintaining the stable dispersion of small particles necessary for fine powder.

Vigorous agitation is a high-energy process that physically overpowers the dispersant's stabilizing effect. It forces the particles to collide with enough energy to stick together, leading to precipitation and the formation of large granules.

Connecting Production Method to Application

The distinct physical properties of fine powder and granular resin make them suitable for completely different industrial uses. The production method is chosen specifically to achieve the desired end-use characteristics.

- If your primary focus is creating thin films, coatings, or wire insulation: You need the small particle size and paste-forming ability of PTFE fine powder, which is only achievable through dispersion polymerization.

- If your primary focus is manufacturing solid blocks, rods, or molded components: You need the free-flowing, larger particles of PTFE granular resin, which is created using suspension polymerization.

Ultimately, controlling the polymerization environment is how manufacturers engineer the precise physical form of PTFE required for its intended application.

Summary Table:

| Production Method | Key Ingredient | Agitation Level | Resulting PTFE Form | Primary Applications |

|---|---|---|---|---|

| Dispersion Polymerization | Dispersant (Surfactant) | Gentle | Fine Powder | Thin films, coatings, wire insulation |

| Suspension Polymerization | Little/No Dispersant | Vigorous | Granular Resin | Solid blocks, rods, molded parts |

Need high-precision PTFE components tailored to your application? At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in PTFE properties ensures superior performance and durability. Contact us today to discuss your project and leverage our precision production capabilities!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs