At its core, a PTFE lip seal is a composite component designed for demanding applications. It consists of a precisely formed sealing element, made from Polytetrafluoroethylene (PTFE), which is mechanically secured or bonded into a rigid metal casing. This construction leverages the unique low-friction and high-resistance properties of PTFE while using the metal case to provide structural integrity and a secure fit.

The fundamental design of a PTFE lip seal combines a specialized, high-performance polymer (PTFE) for the dynamic sealing surface with a metal case for static sealing and structural support. This two-part construction is the key to its performance in extreme temperatures, high speeds, and aggressive chemical environments.

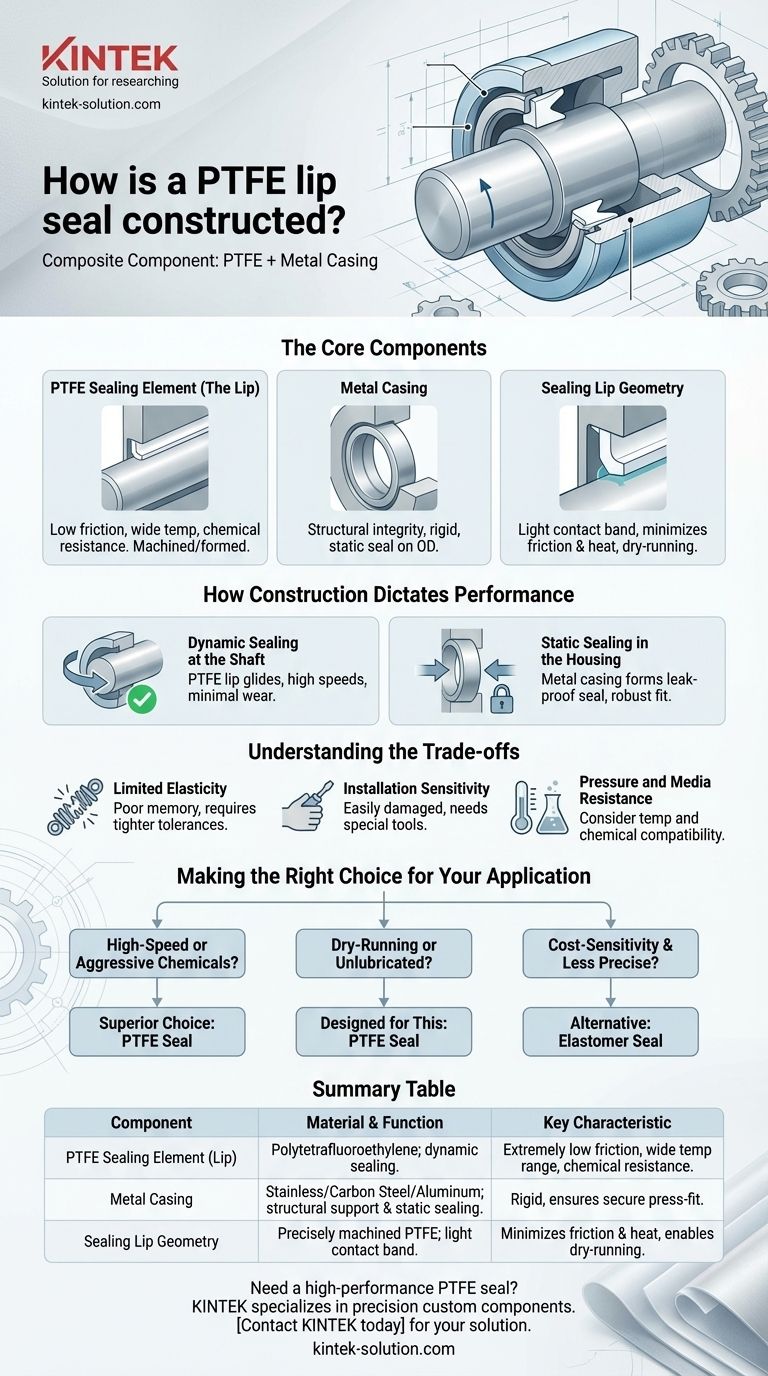

The Core Components of a PTFE Lip Seal

Understanding the seal's performance begins with understanding its individual parts and the materials used to create them.

The PTFE Sealing Element (The Lip)

The heart of the seal is the lip, which is manufactured from polytetrafluoroethylene (PTFE), a fluoropolymer sometimes known by the brand name Teflon.

This material is chosen for its exceptional properties, including extremely low friction, the ability to withstand a wide range of temperatures, and near-universal chemical resistance.

The PTFE element is not molded in the same way as rubber; it is often machined from tube stock or formed through a process of skiving and heating to create a precise, thin sealing lip.

The Metal Casing

The PTFE lip is housed within a metal casing, typically made of stainless steel, carbon steel, or aluminum.

This case provides the necessary structural rigidity for the entire seal. It allows the seal to be press-fit into a housing bore, creating a secure and reliable static seal on its outer diameter.

The Sealing Lip Geometry

The specific shape of the PTFE lip is critical to its function. Unlike elastomeric (rubber) seals that use high radial force, PTFE lips are designed for a light, controlled contact band against the shaft.

This design minimizes friction and heat generation, enabling the seal to operate at high rotational speeds without lubricants, a condition known as dry running.

How Construction Dictates Performance

The two-part construction directly translates to how the seal functions within an assembly, creating two distinct sealing points.

Dynamic Sealing at the Shaft

The primary function—sealing against a rotating shaft—is performed by the PTFE lip. Its low-friction surface glides against the shaft, preventing leakage with minimal wear and energy loss.

This is what allows PTFE seals to handle surface speeds that would quickly destroy a traditional rubber seal.

Static Sealing in the Housing

The metal casing performs the static sealing function. When pressed into the equipment housing, its rigid outer diameter forms a tight, leak-proof seal against the bore, preventing any fluid from bypassing the seal assembly.

This robust press-fit ensures the seal remains securely in place during operation, even under pressure.

Understanding the Trade-offs

While highly effective, the unique construction of PTFE seals introduces specific trade-offs compared to traditional elastomer seals.

Limited Elasticity

PTFE is a relatively rigid plastic with poor "elastic memory." It does not rebound to its original shape as effectively as rubber.

This means it is less forgiving of imperfections in the shaft or housing geometry and requires tighter manufacturing tolerances.

Installation Sensitivity

Because the PTFE lip is less flexible, it can be easily damaged during installation if not handled correctly. A scratch or fold in the lip can create a permanent leak path.

Specialized installation tools are often required to gently guide the seal over sharp edges on a shaft.

Pressure and Media Resistance

The performance of the seal is dictated by the PTFE element. When selecting a seal, you must consider its ability to withstand the application's operating temperatures and its chemical resistance to the media being sealed.

Making the Right Choice for Your Application

The construction of a PTFE lip seal is purposefully engineered for specific, challenging conditions. Understanding this allows you to select the right seal for your goal.

- If your primary focus is high-speed rotation or aggressive chemicals: The combination of a low-friction PTFE lip and a rigid metal case makes this seal the superior choice.

- If your primary focus is sealing in a dry-running or unlubricated environment: The self-lubricating nature of the PTFE sealing element is specifically designed for this condition.

- If your primary focus is cost-sensitivity with less precise hardware: A traditional elastomer (rubber) lip seal may be more appropriate due to its lower cost and greater elasticity.

This focused design makes the PTFE lip seal an indispensable component for high-performance machinery.

Summary Table:

| Component | Material & Function | Key Characteristic |

|---|---|---|

| PTFE Sealing Element (Lip) | Polytetrafluoroethylene (PTFE); provides dynamic sealing. | Extremely low friction, wide temperature range, chemical resistance. |

| Metal Casing | Stainless steel, carbon steel, or aluminum; provides structural support and static sealing. | Rigid, ensures secure press-fit into housing bore. |

| Sealing Lip Geometry | Precisely machined PTFE; creates a light contact band against the shaft. | Minimizes friction and heat, enables dry-running operation. |

Need a high-performance PTFE seal for your demanding application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your seals deliver reliable performance in extreme temperatures, high speeds, and aggressive chemical environments.

Whether you require a prototype or a high-volume order, we deliver the precision and quality your equipment demands.

Contact KINTEK today to discuss your specific sealing challenges and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Is ePTFE gasket material safe for food and pharmaceutical applications? Ensuring Purity and Compliance

- What are the advantages of using a PTFE lined ball valve? Achieve Superior Corrosion Resistance & Leak-Proof Sealing

- What are the primary uses of Expanded PTFE? Unlock Its Unique Properties for Your Application

- What are the thermal properties of PTFE that make it ideal for seals? Ensuring Reliability in Extreme Conditions

- What are the key properties and applications of machined Teflon? Solve Extreme Engineering Challenges

- What are the installation advantages of PTFE expansion bellows? Reduce Labor, Time, and Equipment Needs

- What benefits do Teflon sheets provide in DTG printing? Achieve Consistent, Professional Prints

- Which type of oil seal is better for extreme temperature and chemical environments? The Definitive Guide to PTFE Seals