At its core, a Polytetrafluoroethylene (PTFE) bush is designed as a simple cylindrical or ring-like component. Its primary purpose is to fit between two moving parts, such as a shaft and its housing, to serve as a low-friction, wear-resistant barrier. The true sophistication of its design, however, is not in its shape but in the inherent material properties of PTFE that allow it to function without external lubrication.

The design of a PTFE bush is a masterclass in material science. Its simple physical form is intentionally minimal, designed to leverage PTFE's unique combination of self-lubrication, chemical inertness, and thermal stability to solve complex friction and wear problems.

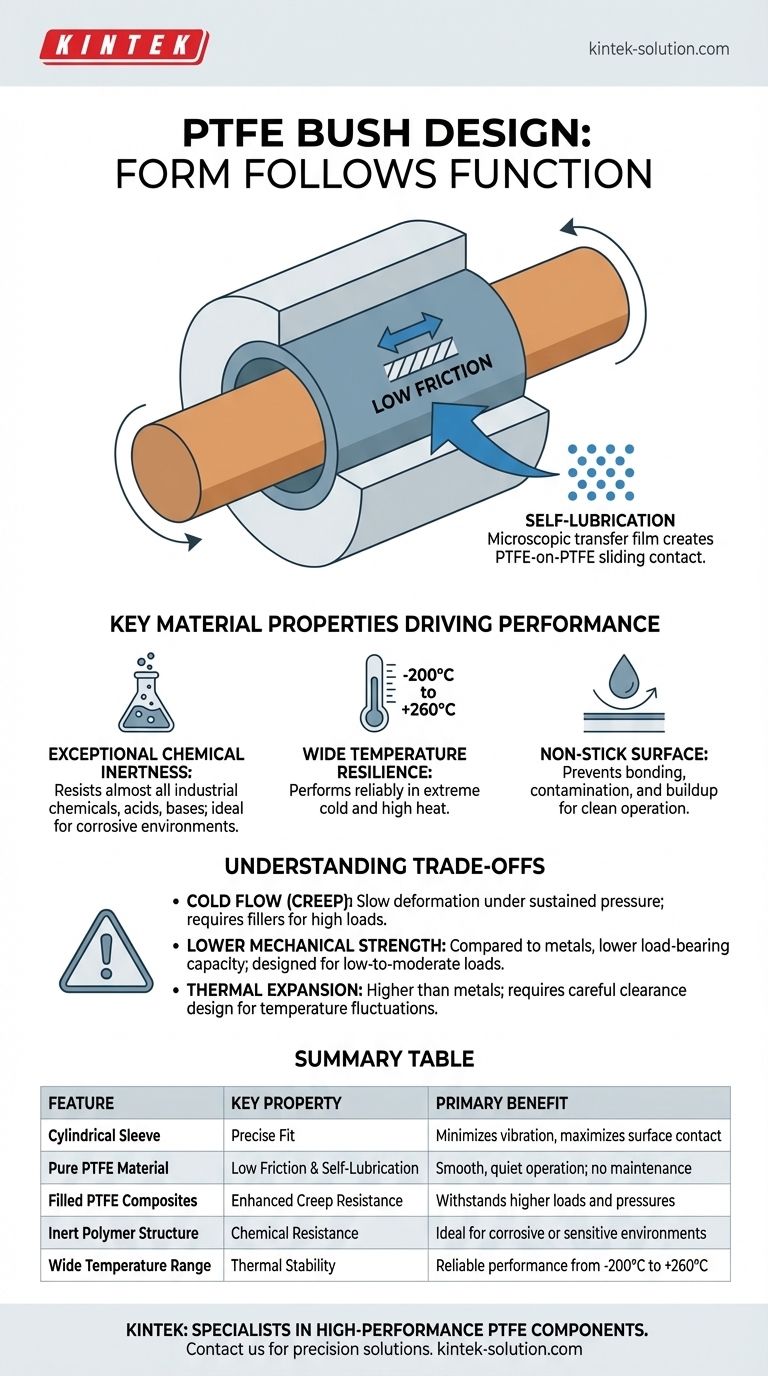

The Foundational Design: Form Follows Function

The effectiveness of a PTFE bush comes from its ability to separate surfaces and drastically reduce the energy required to move them. This is achieved through a combination of its physical shape and its exceptional material characteristics.

The Core Physical Structure

A PTFE bush is most often a plain sleeve or flanged bearing. This hollow cylindrical shape is designed to be press-fit into a housing, providing a smooth, low-friction surface for a rotating or sliding shaft to move against.

Its dimensions—inner diameter, outer diameter, and length—are engineered to match the specific shaft and housing, ensuring a precise fit that minimizes vibration and maximizes surface contact.

The Principle of Low Friction

The primary design feature of PTFE is its remarkably low coefficient of friction, one of the lowest of any solid material. This property is fundamental to its function.

This means that surfaces slide against the PTFE bush with minimal resistance, which reduces heat generation, minimizes energy loss, and ensures smooth, quiet operation.

Inherent Self-Lubrication

Unlike traditional metal bearings that require grease or oil, PTFE is self-lubricating. During initial operation, a microscopic transfer film of PTFE is deposited onto the mating surface.

This process creates a highly effective PTFE-on-PTFE sliding contact, eliminating the need for external lubricants, which simplifies machine design and dramatically reduces maintenance requirements.

Key Material Properties Driving the Design

The simple geometry of a PTFE bush allows the powerful properties of the material to define its performance. Engineers select PTFE when the operating environment demands more than just low friction.

Exceptional Chemical Inertness

PTFE is virtually inert and does not react with almost any industrial chemical, acid, or base. This makes it an essential design choice for equipment used in corrosive environments, such as chemical processing plants.

This non-reactivity also means it is non-toxic and insoluble, making it ideal for sensitive applications in the food, pharmaceutical, and medical industries.

Wide Temperature Resilience

The material is designed to perform reliably across an enormous temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This thermal stability allows PTFE bushes to be designed into applications experiencing extreme cold, such as cryogenic equipment, or high heat, like industrial ovens.

Non-Stick Surface

PTFE's non-adhesive, non-stick surface prevents other materials from bonding to it. This design feature is critical for preventing contamination and buildup.

It ensures that the bush remains clean and that its performance is not degraded by sticky substances, which is vital in food processing and manufacturing.

Understanding the Trade-offs

While powerful, the design of a PTFE bush is not without limitations. Understanding these trade-offs is crucial for successful implementation.

Resistance to Cold Flow (Creep)

Pure PTFE can be susceptible to "cold flow," or creep—a slow deformation under sustained pressure. This is a critical design consideration for high-load applications.

To counteract this, PTFE is often blended with fillers like glass fiber, carbon, or bronze. These composite materials significantly improve mechanical strength and creep resistance, but may slightly alter other properties like the friction coefficient or chemical compatibility.

Lower Mechanical Strength

Compared to bronze or steel bearings, PTFE bushes have a lower compressive strength and load-bearing capacity. They are designed for low-to-moderate load applications.

Attempting to use a standard PTFE bush in a high-load scenario where a metal bearing is required can lead to premature failure.

Thermal Expansion

PTFE has a higher rate of thermal expansion than metals. This must be accounted for in the design of the housing and shaft clearances, especially in applications with significant temperature fluctuations, to prevent the bush from binding.

Making the Right Choice for Your Goal

The optimal design for a PTFE bush is determined entirely by its intended application.

- If your primary focus is low friction in a clean or corrosive environment: A pure, unfilled PTFE bush is the ideal choice for its superior lubricity and chemical inertness.

- If your application involves significant mechanical load or pressure: Specify a filled PTFE composite (e.g., with glass, carbon, or bronze) to gain the necessary resistance to wear and cold flow.

- If the goal is to eliminate maintenance and noise: PTFE's self-lubricating properties make it a superior choice over traditional greased metal bearings for long-term, quiet operation.

Ultimately, designing with a PTFE bush is about harnessing the right material properties to create a simple, elegant, and highly effective engineering solution.

Summary Table:

| Design Feature | Key Property | Primary Benefit |

|---|---|---|

| Cylindrical Sleeve Shape | Precise Fit | Minimizes vibration, maximizes surface contact |

| Pure PTFE Material | Low Friction & Self-Lubrication | Smooth, quiet operation; no maintenance |

| Filled PTFE Composites | Enhanced Creep Resistance | Withstands higher loads and pressures |

| Inert Polymer Structure | Chemical Resistance | Ideal for corrosive or sensitive environments |

| Wide Temperature Range | Thermal Stability | Reliable performance from -200°C to +260°C |

Need a Precision PTFE Component for Your Application?

KINTEK specializes in manufacturing high-performance PTFE components—including custom bushes, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with expert material science to deliver solutions that enhance performance, reduce maintenance, and withstand demanding environments.

Let us help you harness the power of PTFE:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Guidance on pure or filled PTFE for your specific load, chemical, and temperature requirements.

- Quality Assurance: Components built for reliability and long-term performance.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications