At its core, the difference is one of manufactured structure. A pure PTFE gasket is a solid, dense material, whereas an expanded PTFE (ePTFE) gasket is created through a process that transforms the same polymer into a soft, porous, and highly fibrous structure. This fundamental structural change is what gives ePTFE its vastly superior sealing capabilities.

The critical takeaway is that while both gaskets are made from the same chemically inert polymer, the porous, multi-directional fibrous structure of expanded PTFE allows it to compress and conform to imperfect surfaces far more effectively than the rigid, solid structure of pure PTFE.

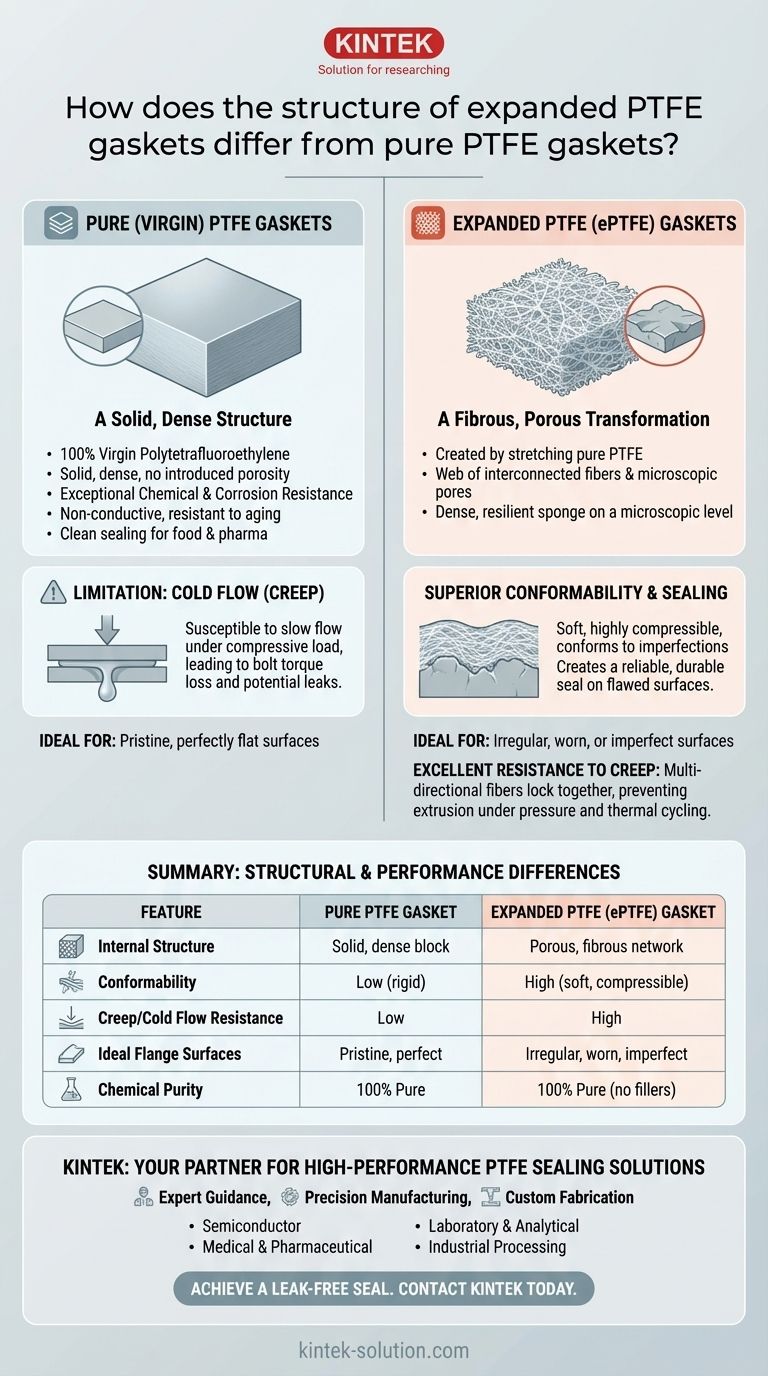

The Foundation: Pure (Virgin) PTFE Gaskets

A Solid, Dense Structure

Pure PTFE gaskets are made from 100% virgin polytetrafluoroethylene. Structurally, the material is solid and dense, without any introduced porosity or voids.

Key Properties

This simple, pure composition gives the material its well-known benefits: exceptional chemical and corrosion resistance, non-conductivity, and resistance to aging. It's a clean sealing solution that will not contaminate the process media, making it suitable for food and pharmaceutical applications.

The Inherent Limitation: Cold Flow

The primary drawback of this solid structure is its susceptibility to creep, or cold flow. Under the compressive load of a flange, the solid PTFE material can slowly flow or squeeze out from between the flanges, leading to a loss of bolt torque and potential leaks.

The Innovation: Expanded PTFE (ePTFE) Gaskets

A Transformation to a Fibrous Structure

Expanded PTFE is created by physically stretching pure PTFE under specific conditions. This process radically alters its internal structure, creating a web of interconnected fibers and microscopic pores.

Instead of a solid block, ePTFE is more like a dense, resilient sponge on a microscopic level.

Superior Conformability and Sealing

This porous, fibrous structure is soft and highly compressible. It allows the gasket to easily conform to flange imperfections, such as scratches, warping, or irregularities.

Where a rigid, pure PTFE gasket might only make contact on the high points of a flawed surface, an ePTFE gasket fills in the valleys, creating a much more reliable and durable seal.

Overcoming Creep and Cold Flow

The multi-directional, interlocking nature of the fibrous web gives ePTFE excellent resistance to creep and cold flow. When compressed, the fibers lock together, preventing the material from extruding out of the flange.

This structural integrity ensures a more stable and long-lasting seal, even under significant pressure and thermal cycling.

Understanding the Trade-offs

Pure PTFE: Simplicity and Purity

Pure PTFE is an effective choice for general-purpose applications where sealing surfaces are perfectly flat and smooth. Its primary advantage is its absolute purity for sensitive industries.

However, its rigidity makes it a poor choice for the demanding conditions found in most real-world industrial environments with older or worn equipment.

Expanded PTFE: Performance on Imperfect Surfaces

Expanded PTFE is the superior performance material for nearly all industrial sealing applications. Its ability to compensate for flange deformation and resist creep makes it the default choice for reliability.

It maintains the outstanding chemical resistance of pure PTFE because no fillers or additives are used in its creation.

A Note on Filled PTFE

Filled PTFE gaskets are a third category where materials like glass fiber or graphite are added to pure PTFE. This is a different method to improve creep resistance and strength.

While effective, this approach alters the chemical purity of the material, unlike ePTFE which enhances mechanical properties through a purely structural transformation.

How to Choose the Right PTFE Gasket

Choosing the correct gasket requires matching the material's structure to your application's demands.

- If your primary focus is absolute purity on pristine, perfectly machined surfaces: Pure (Virgin) PTFE is a clean and effective solution.

- If your primary focus is creating a durable, leak-free seal on irregular or older flanges: Expanded PTFE’s conformability and creep resistance provide unmatched reliability.

- If your primary focus is enhanced mechanical strength and temperature resistance beyond standard PTFE: A Filled PTFE gasket might be the most appropriate engineered choice.

Understanding that the internal structure dictates performance is the key to making the right engineering decision for a reliable seal.

Summary Table:

| Feature | Pure PTFE Gasket | Expanded PTFE (ePTFE) Gasket |

|---|---|---|

| Internal Structure | Solid, dense block | Porous, fibrous network |

| Conformability | Low (rigid) | High (soft, compressible) |

| Creep/Cold Flow Resistance | Low | High |

| Ideal for Flange Surfaces | Pristine, perfectly flat | Irregular, worn, or imperfect |

| Chemical Purity | 100% pure | 100% pure (no fillers) |

Need a Reliable, High-Performance PTFE Sealing Solution?

Understanding the structural differences between PTFE gaskets is the first step. The next is sourcing the right component for your specific application. KINTEK specializes in manufacturing precision PTFE components, including seals, gaskets, liners, and custom labware.

We serve a wide range of demanding industries, including:

- Semiconductor

- Medical & Pharmaceutical

- Laboratory & Analytical

- Industrial Processing

Our value to you:

- Expert Guidance: Our team helps you select the optimal PTFE material (Pure, Expanded, or Filled) for your unique pressure, temperature, and chemical resistance requirements.

- Precision Manufacturing: We prioritize quality and consistency in every component we produce.

- Custom Fabrication: We support your projects from initial prototypes to high-volume production runs.

Let us help you achieve a leak-free, durable seal. Contact KINTEK today to discuss your PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications