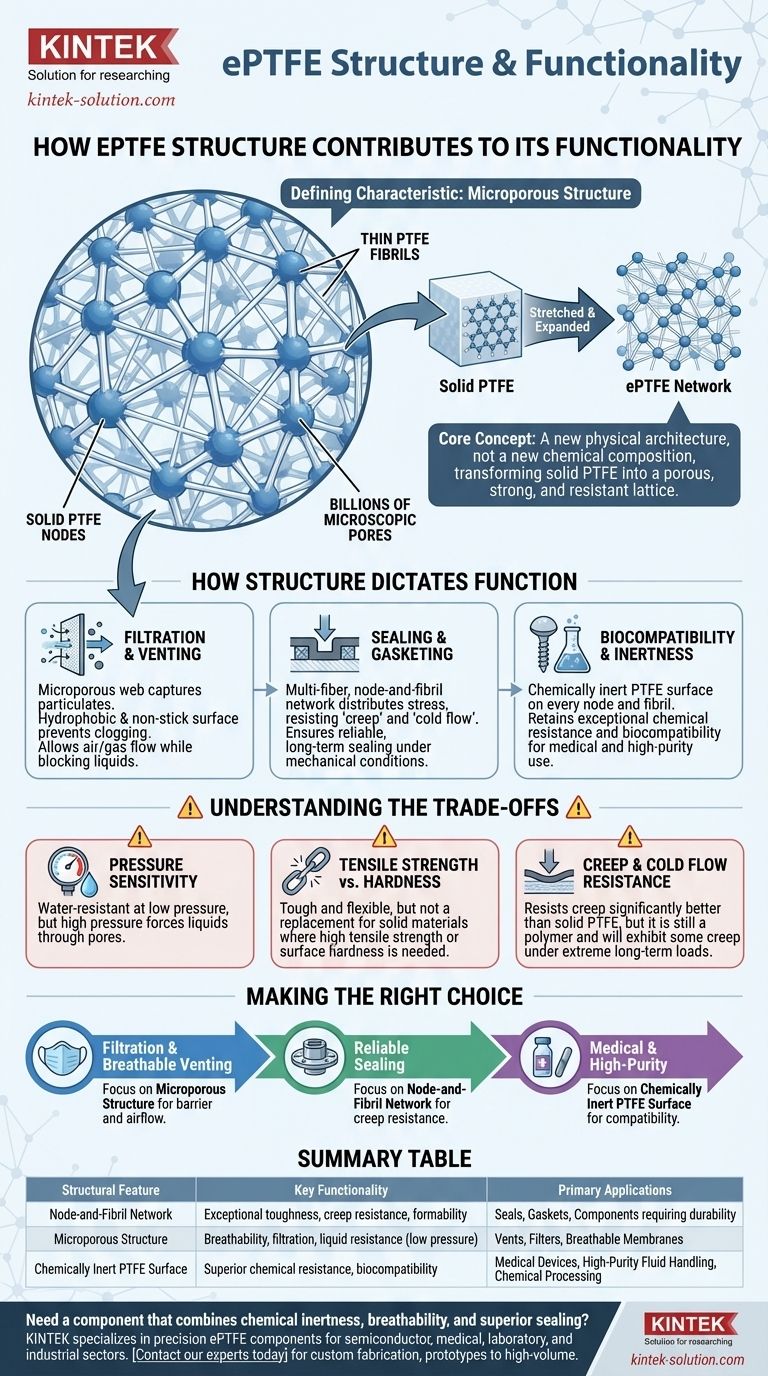

The defining characteristic of expanded Polytetrafluoroethylene (ePTFE) is its unique microporous structure, consisting of a web-like network of solid nodes interconnected by thin fibrils. This physical arrangement is the key to its functionality, as it allows the material to retain the desirable properties of standard PTFE—like chemical inertness and hydrophobicity—while introducing new capabilities like breathability and exceptional mechanical toughness.

At its core, ePTFE's functionality does not come from a new chemical composition, but from a new physical architecture. The expansion process transforms solid PTFE into a microscopic lattice, creating a material that is simultaneously porous, strong, and highly resistant to chemicals and temperature.

The Foundation: From Solid to Microporous

The creation of ePTFE involves the controlled stretching, or expansion, of standard Polytetrafluoroethylene (PTFE). This process pulls the molecular structure of the solid PTFE apart, forming a sophisticated three-dimensional web.

### The Node-and-Fibril Network

The resulting structure is not simply a foam but a highly organized network of solid PTFE nodes connected by extremely thin PTFE fibrils. This multi-fiber architecture is fundamental to its mechanical performance.

This network distributes stress across the entire material, providing exceptional toughness and formability. It is this structure that fundamentally addresses common failure points in other PTFE materials.

### Billions of Microscopic Pores

The spaces created between the nodes and fibrils form billions of microscopic pores. The size of these pores can be precisely controlled during manufacturing.

This microporosity is what allows ePTFE to be permeable to air and other gases while remaining resistant to liquid water penetration at low pressures.

How Structure Dictates Function

Each element of ePTFE's architecture directly translates to a specific, high-value performance characteristic. Understanding this link is key to leveraging the material effectively.

### Filtration and Venting

The microporous web structure makes ePTFE an exceptional filtration medium. The pores are small enough to capture and remove particulate matter from a fluid stream (liquid or gas) that is forced through it.

Simultaneously, the inherent hydrophobic (water-repelling) and non-stick nature of the PTFE surface helps prevent the membrane from becoming clogged, allowing for easy cleaning and long service life. For venting applications, it allows air and gas to pass through while blocking liquid contaminants like water.

### Sealing and Gasketing

For sealing applications, the multi-fiber, node-and-fibril structure is the most critical feature. This interwoven network provides a unique combination of compressibility and strength.

Unlike solid PTFE, which can be prone to "creep" or "cold flow" (a slow deformation under pressure), the ePTFE network resists this deformation. This structural integrity ensures a reliable, long-term seal even under severe mechanical conditions.

### Biocompatibility and Chemical Inertness

The surface of every node and fibril in the structure is pure, chemically inert PTFE. The expansion process does not alter its chemical makeup.

This means ePTFE retains the exceptional chemical resistance and biocompatibility of the original material. This makes it ideal for medical implants, high-purity fluid transport, and use in harsh chemical environments where material degradation is a primary concern.

Understanding the Trade-offs

While its structure provides unique advantages, it's crucial to recognize its limitations to ensure proper application.

### Pressure Sensitivity

The defining feature of ePTFE—its porosity—is also a key constraint. While it is water-resistant at low pressure, sufficiently high pressure will force liquids through its pores. This characteristic must be accounted for in high-pressure sealing and containment designs.

### Tensile Strength vs. Hardness

The expansion process creates a material that is exceptionally tough and flexible for its weight, but it is not a replacement for solid materials like metal or rigid plastics in applications requiring high tensile strength or surface hardness.

### Creep and Cold Flow Resistance

Although ePTFE offers a dramatic improvement over solid PTFE, it is still a polymer. In applications with extreme long-term loads and high temperatures, it will exhibit different creep characteristics than metal or ceramic gaskets. It resists creep; it does not eliminate it entirely.

Making the Right Choice for Your Application

To leverage ePTFE effectively, match its primary structural benefit to your main engineering goal.

- If your primary focus is filtration or breathable venting: The key is the microporous structure, which provides a barrier to particulates and liquids while allowing air and vapor to pass through.

- If your primary focus is reliable sealing: The critical feature is the node-and-fibril network, which delivers exceptional resistance to the creep and cold flow that compromises other PTFE seals.

- If your primary focus is medical or high-purity use: The advantage lies in the combination of a chemically inert PTFE surface with a porous structure suitable for everything from implants to advanced fluid purification.

By understanding how its unique architecture governs its performance, you can confidently apply ePTFE to solve your most demanding engineering challenges.

Summary Table:

| Structural Feature | Key Functionality | Primary Applications |

|---|---|---|

| Node-and-Fibril Network | Exceptional toughness, creep resistance, and formability. | Seals, Gaskets, Components requiring mechanical durability. |

| Microporous Structure | Breathability, filtration, and liquid resistance at low pressure. | Vents, Filters, Breathable Membranes. |

| Chemically Inert PTFE Surface | Superior chemical resistance and biocompatibility. | Medical Devices, High-Purity Fluid Handling, Chemical Processing. |

Need a component that combines chemical inertness, breathability, and superior sealing? KINTEK specializes in manufacturing precision ePTFE components (seals, liners, membranes, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication expertise, from prototypes to high-volume orders, ensures you get a solution perfectly tailored to your application's demands. Contact our experts today to discuss how our ePTFE components can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the common applications of PTFE in aggressive chemical environments? Ensure Reliability and Safety

- Why is PTFE compliance with USDA and FDA standards important? Ensure Safety in Food, Pharma & Medical

- How are PTFE coatings applied? A Guide to Spray, Electrostatic, and Dip-Spin Methods

- What are the differences between PTFE and Nylon? Choose the Right Material for Your Application

- What makes PTFE chemically inert? Discover the Molecular Secrets of its Unmatched Resistance

- What are the advantages of using Teflon? Achieve Superior Performance in Extreme Conditions

- Why is PTFE ideal for high-purity applications? Ensuring Absolute Chemical and Biological Inertness

- How do molybdenum disulfide fillers improve PTFE? Enhance Wear Resistance and Lubricity