At its core, a PTFE ball valve operates through a simple quarter-turn rotation. It controls flow using a spherical ball with a hole, or bore, through its center. When the bore is aligned with the pipeline, the valve is fully open. A 90-degree turn of the handle or actuator rotates the ball so its solid sides block the flow path, creating a tight seal against soft Polytetrafluoroethylene (PTFE) seats.

The mechanical simplicity of a ball valve is common, but its performance is defined by its Polytetrafluoroethylene (PTFE) components. The unique properties of PTFE—its extreme chemical inertness and low-friction surface—are what make this valve a uniquely reliable, low-maintenance solution for controlling corrosive or high-purity media.

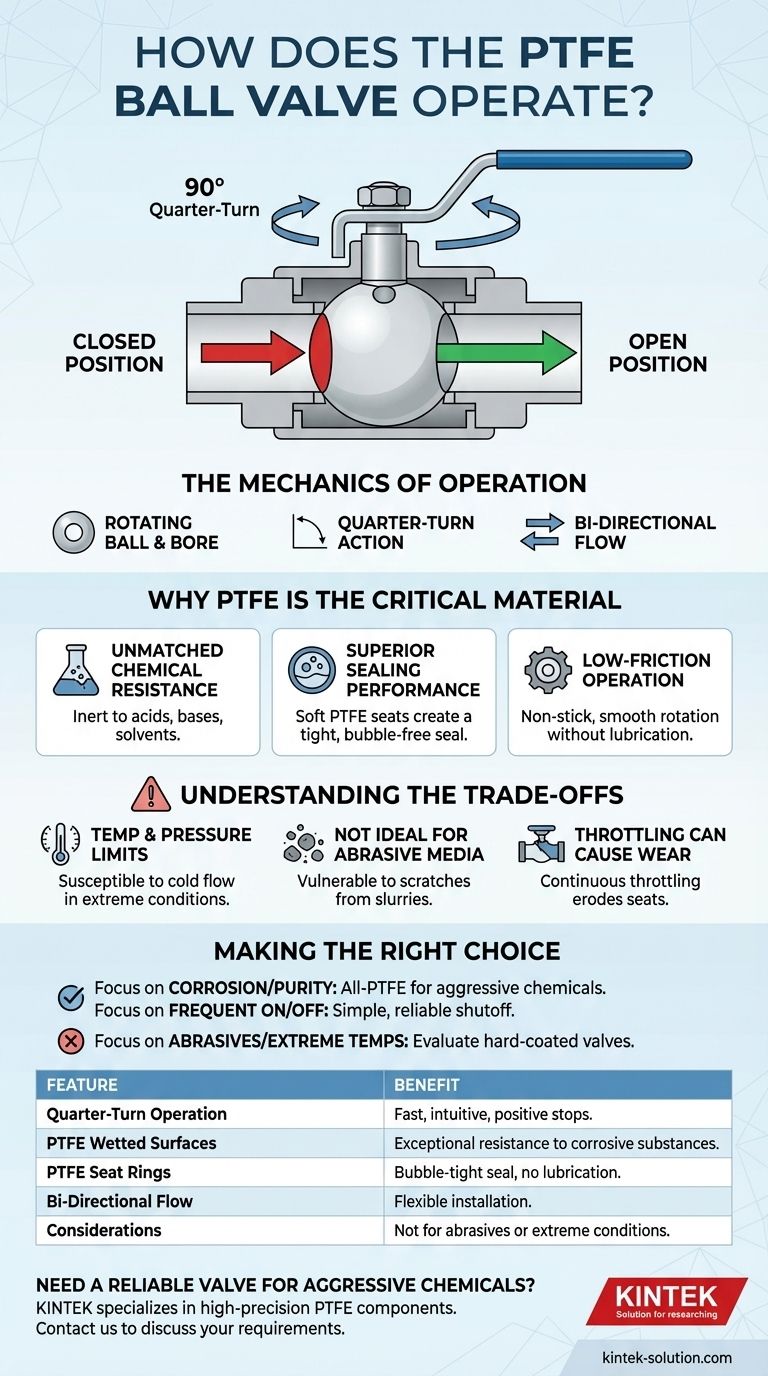

The Mechanics of Operation

A PTFE ball valve's design is elegant in its simplicity, focusing on reliable shutoff through a minimal number of moving parts.

The Rotating Ball and Bore

The central component is a sphere with a cylindrical hole drilled through it. This ball is connected to a stem, which extends outside the valve body to connect to a handle or actuator.

The Quarter-Turn Action

The valve moves from fully open to fully closed with a simple 90-degree turn. This quarter-turn action makes operation extremely fast and intuitive. Most models include positive stops to provide clear tactile feedback for the fully open and closed positions.

Bi-Directional Flow

The symmetrical design of the ball and seats allows the process medium to flow through the valve in either direction without affecting its performance or sealing capability.

Why PTFE is the Critical Material

While the mechanism is simple, the choice of material is what elevates this valve's performance. PTFE, the same material as Teflon, is used for all surfaces that come into contact with the fluid.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials available. This makes it ideal for handling highly corrosive acids, bases, and solvents that would quickly degrade metal or other polymer components.

Superior Sealing Performance

The valve's ball is sealed by exchangeable PTFE seat rings. PTFE is soft enough to deform slightly under pressure, creating an exceptionally tight, bubble-free seal against the ball. Its resistance to chemical degradation ensures this seal remains effective over a long service life.

Low-Friction Operation

PTFE has an extremely low coefficient of friction. This non-stick property means the ball turns smoothly against the seats without any need for lubrication. This results in low torque requirements, making manual operation easy and allowing for smaller, less expensive actuators in automated systems.

Understanding the Trade-offs

No component is perfect for every situation. Objectivity requires acknowledging where a PTFE ball valve might not be the optimal choice.

Temperature and Pressure Limits

While suitable for high ambient temperatures, PTFE is a polymer that can be susceptible to "cold flow" or deformation under high-pressure and high-temperature combinations. It does not have the rigidity of metal-seated valves in extreme service conditions.

Not Ideal for Abrasive Media

The same softness that makes PTFE an excellent sealing material also makes it vulnerable to abrasive particles. Slurries or fluids with suspended solids can scratch or erode the PTFE seats, eventually compromising the seal and causing leaks.

Throttling Can Cause Wear

Although the valve can be held in a partially open position to meter flow, it is primarily designed for on/off service. Continuous throttling can cause high-velocity fluid to erode the section of the PTFE seat exposed to the flow, leading to premature wear.

Making the Right Choice for Your Application

Selecting the correct valve depends entirely on the demands of your specific process.

- If your primary focus is corrosion resistance or purity: The all-PTFE wetted surfaces make this valve the definitive choice for aggressive chemicals or systems where media contamination is unacceptable.

- If your primary focus is frequent, on/off operation: The simple, low-torque quarter-turn action and long, maintenance-free service life are ideal for applications requiring fast and reliable shutoff.

- If your primary focus is handling abrasive slurries or extreme temperatures: You should evaluate a hard-coated or metal-seated ball valve, as they are specifically designed to withstand abrasion and maintain integrity under higher thermal stress.

By understanding these core principles, you can confidently deploy the PTFE ball valve where its unique material advantages will deliver maximum reliability and performance.

Summary Table:

| Feature | Benefit |

|---|---|

| Quarter-Turn Operation | Fast, intuitive open/close action with positive stops. |

| PTFE Wetted Surfaces | Exceptional resistance to corrosive acids, bases, and solvents. |

| PTFE Seat Rings | Creates a bubble-tight seal without needing lubrication. |

| Bi-Directional Flow | Can be installed without regard to flow direction. |

| Considerations | Not ideal for abrasive slurries or extreme temperature/pressure combinations. |

Need a reliable valve for aggressive chemicals?

KINTEK specializes in manufacturing high-precision PTFE components, including ball valves, seals, and custom labware. Our valves are engineered for maximum reliability and chemical resistance in the most demanding semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the exact solution for your process.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE expertise can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the difference between carbon and graphite as fillers in PTFE? Optimize Strength vs. Lubricity

- Why is it important to consider the whole lifecycle cost when evaluating Teflon gland packing? Uncover the True Cost of Ownership

- What are PTFE envelope gaskets used for? Protect Delicate Flanges & Seal Aggressive Chemicals

- What challenges are associated with fabricating PTFE substrates? Mastering Precision with High-Frequency Materials

- What are the different types of Teflon gland packing available? Select the Right PTFE Seal for Your Application

- What are the limitations of machining Teflon (PTFE)? Overcome Challenges for Precision Parts

- What makes extruded PTFE rods chemically resistant? Unmatched Stability from its Molecular Structure

- How is PTFE used in ball valves and Y strainers? Essential for Leak-Proof Seals & Chemical Resistance