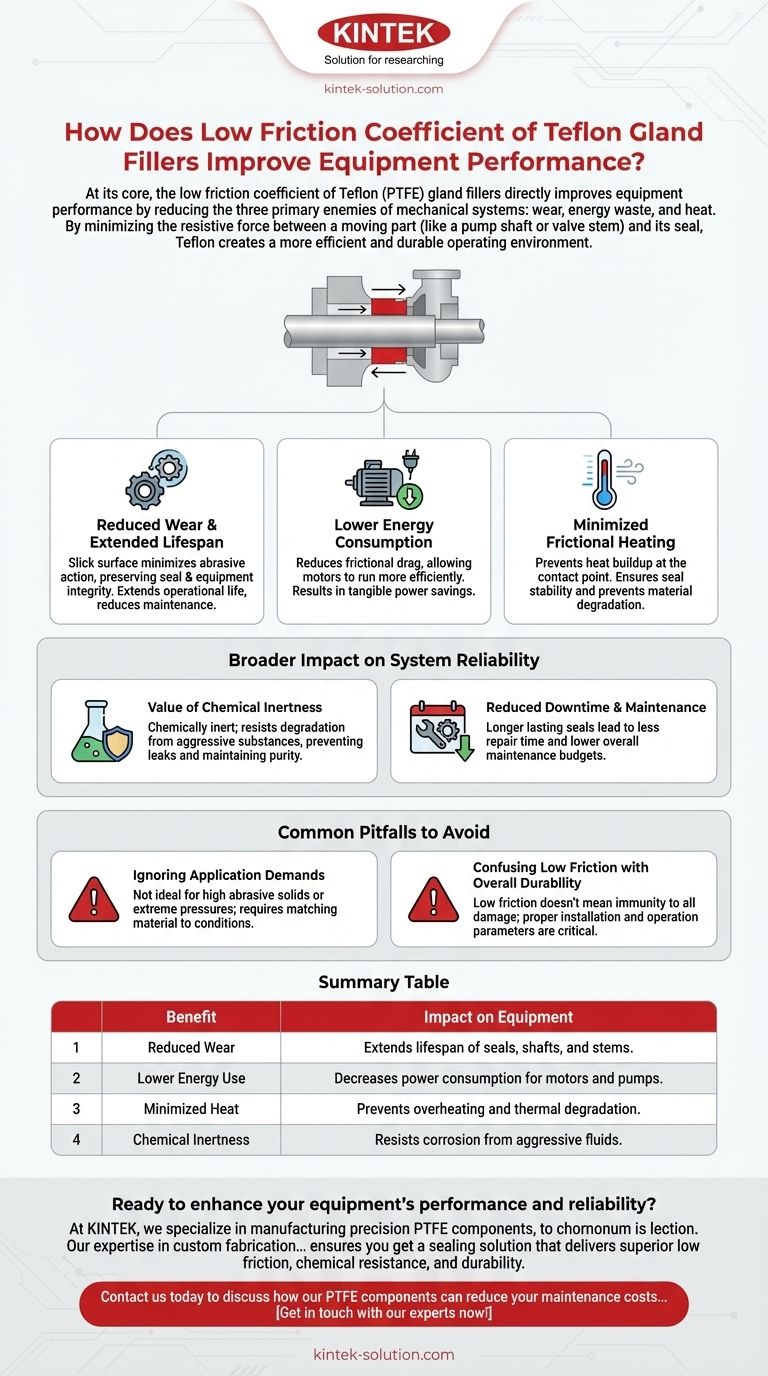

At its core, the low friction coefficient of Teflon (PTFE) gland fillers directly improves equipment performance by reducing the three primary enemies of mechanical systems: wear, energy waste, and heat. By minimizing the resistive force between a moving part (like a pump shaft or valve stem) and its seal, Teflon creates a more efficient and durable operating environment.

While often seen as a simple material choice, selecting Teflon for its low friction is a strategic decision. It initiates a chain reaction that lowers energy consumption, extends the lifespan of critical components, and reduces the risk of heat-induced failure.

How Low Friction Translates to Tangible Benefits

The exceptionally low friction of Teflon is not just a theoretical property; it has direct, measurable effects on machine performance and longevity.

Reduced Wear and Extended Lifespan

Friction is a physical abrasive force. In equipment like pumps or valves, a gland filler is in constant contact with a moving shaft or stem.

A higher friction material constantly scrapes against the metal, leading to scoring and gradual wear. Teflon's slick surface minimizes this abrasive action, preserving the integrity of both the sealing material and the equipment itself. This extends the operational life of the machinery and reduces the need for frequent lubrication.

Lower Energy Consumption

Every motor-driven system must overcome friction to operate. This resistance consumes energy that does not contribute to the machine's primary function, representing a direct operational cost.

By reducing this frictional drag, Teflon gland fillers allow pumps and other rotating equipment to run more efficiently. The motor works less hard to perform the same task, resulting in tangible power savings, especially in high-speed or continuous-duty applications.

Minimized Frictional Heating

The energy lost to friction is primarily converted into heat. In a dynamic sealing application, this heat can build up at the point of contact.

Excessive heat can degrade the sealing material, cause the shaft to expand, and even pose a safety risk with volatile fluids. Teflon's low coefficient of friction prevents this dangerous heat buildup, ensuring the seal remains stable and effective even during demanding operations.

Understanding the Broader Impact on System Reliability

The benefits of a low-friction filler extend beyond a single component, influencing the stability and maintenance requirements of the entire system.

The Value of Chemical Inertness

While friction is a mechanical challenge, chemical attack is an operational one. Teflon gland fillers are chemically inert, meaning they do not react with the vast majority of substances.

This property ensures the seal will not degrade or fail when handling aggressive chemicals, such as those found in chlorine treatment systems. This prevents leaks and maintains the purity and stability of the process.

Reduced Downtime and Maintenance Costs

The combined effects of reduced wear, lower heat, and chemical stability lead to a significant reduction in maintenance needs.

Seals last longer, components are not damaged by friction, and the risk of unexpected failure decreases. This translates directly into less downtime for repairs and lower overall maintenance budgets, representing a significant cost saving over the equipment's lifecycle.

Common Pitfalls to Avoid

While low friction is a powerful advantage, it is crucial to view it as part of a complete sealing solution. Focusing on one property while ignoring others is a common mistake.

Ignoring Application Demands

The primary benefit of Teflon is its low friction and chemical resistance. However, it may not be the ideal choice for applications involving high levels of abrasive solids or extreme pressures where a harder material might be required.

Confusing Low Friction with Overall Durability

A low friction coefficient reduces wear from sliding contact, but it does not necessarily mean the material is immune to all forms of damage. Proper installation and ensuring the equipment operates within its designed parameters are still critical for long-term reliability.

Making the Right Choice for Your Goal

To leverage Teflon's properties effectively, align your material choice with your primary operational objective.

- If your primary focus is maximizing equipment lifespan: The reduction in physical wear on shafts and stems from Teflon's low friction is your most significant benefit.

- If your primary focus is reducing operational costs: The lower energy consumption in pumps and the reduced need for frequent maintenance will deliver the most direct financial return.

- If your primary focus is system stability and safety: The combination of low heat generation and chemical inertness provides a reliable seal that minimizes the risk of failure in critical processes.

Ultimately, understanding the physics of friction empowers you to make smarter engineering and maintenance decisions for your equipment.

Summary Table:

| Benefit | Impact on Equipment |

|---|---|

| Reduced Wear | Extends lifespan of seals, shafts, and stems. |

| Lower Energy Use | Decreases power consumption for motors and pumps. |

| Minimized Heat | Prevents overheating and thermal degradation. |

| Chemical Inertness | Resists corrosion from aggressive fluids. |

Ready to enhance your equipment's performance and reliability?

At KINTEK, we specialize in manufacturing precision PTFE components, including gland fillers, seals, and liners, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that delivers superior low friction, chemical resistance, and durability.

Contact us today to discuss how our PTFE components can reduce your maintenance costs, improve efficiency, and extend the life of your critical equipment.

Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- When and by whom was PTFE discovered? A Tale of Accidental Innovation