In pharmaceutical manufacturing, the high cycle life of Polytetrafluoroethylene (PTFE) diaphragm valves directly translates to superior operational reliability and reduced long-term costs. Because these valves can withstand repeated actuation far longer than alternatives, they significantly minimize the need for process shutdowns for maintenance or replacement. This longevity reduces downtime, lowers labor costs, and enhances overall process efficiency.

The true value of a high cycle life in a pharmaceutical setting is not just economic efficiency, but risk mitigation. By minimizing maintenance interventions, these valves reduce the opportunities for contamination, thereby protecting product purity and ensuring the integrity of validated, sterile processes.

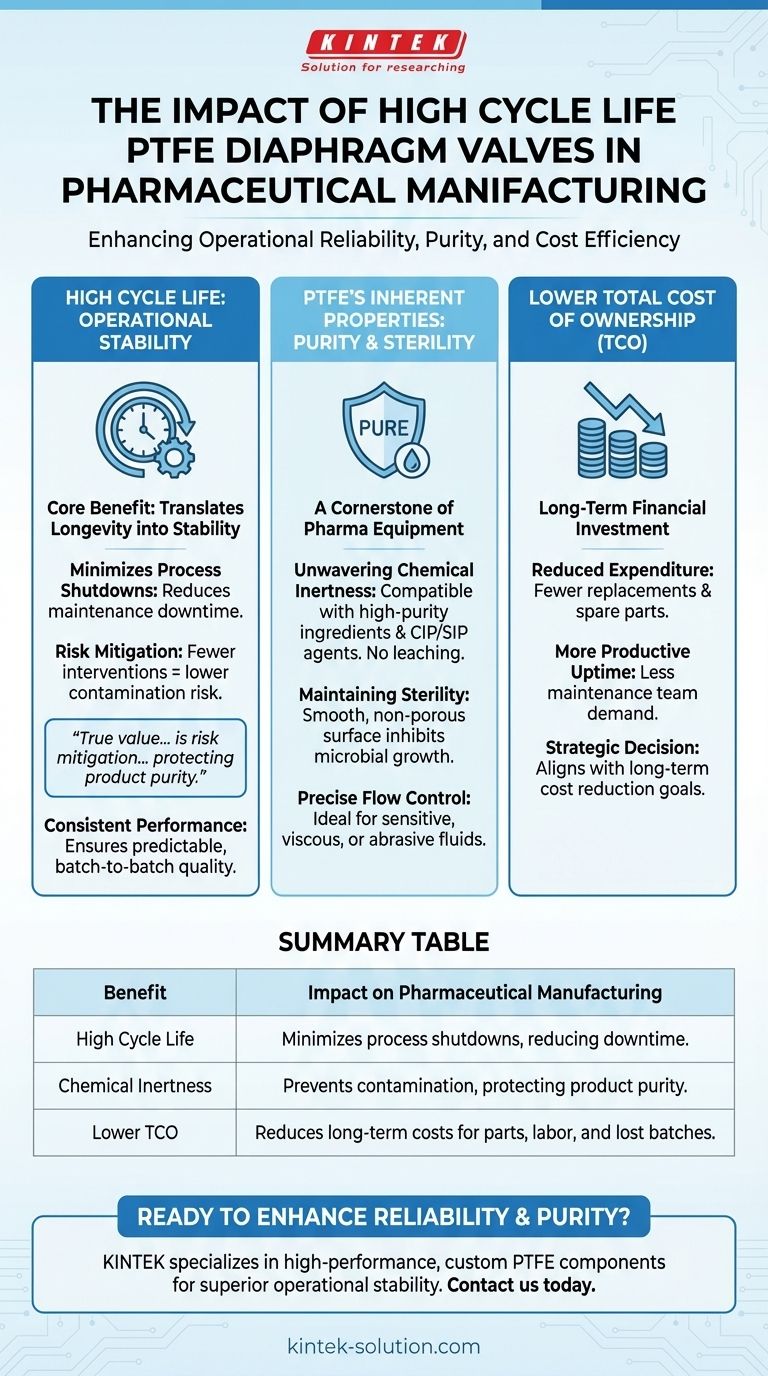

The Core Benefit: Translating Longevity into Operational Stability

A valve's "cycle life" refers to the number of times it can open and close before its performance degrades or it fails. For PTFE diaphragms, this number is exceptionally high, providing a foundation for a stable and predictable manufacturing environment.

Defining High Cycle Life in Practice

A high cycle life means the valve's core component—the PTFE diaphragm—remains functional and effective for a much longer operational period. This durability ensures consistent performance batch after batch, which is critical in a highly regulated industry.

Reducing Unplanned Downtime

In pharmaceutical manufacturing, processes are meticulously validated. An unexpected valve failure causes more than a simple delay; it can force a complete shutdown, risk the loss of an entire high-value batch, and may even require process re-validation. The reliability of high-cycle valves directly prevents these costly disruptions.

Lowering Total Cost of Ownership

While the initial investment may be a consideration, the total cost of ownership is significantly lower. Fewer replacements mean reduced expenditure on spare parts, less demand on maintenance teams, and most importantly, more productive uptime for the manufacturing line.

Why PTFE is a Pharmaceutical Standard

The high cycle life of a PTFE valve is powerful, but it becomes indispensable when combined with the inherent properties of the material itself. This combination is why PTFE is a cornerstone of modern pharmaceutical equipment.

Unwavering Chemical Inertness

PTFE is non-reactive and compatible with a vast range of chemicals. It does not react with high-purity pharmaceutical ingredients or the aggressive cleaning and sterilization agents used in Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems. This ensures the product remains uncontaminated by leached materials from the valve.

Maintaining Sterility and Purity

The surface of PTFE is exceptionally smooth and non-porous, which inhibits microbial growth and prevents particles from adhering to the valve. This low surface adhesion is critical for maintaining sterile conditions and ensuring the purity of the final product.

Precise and Gentle Flow Control

Diaphragm valves are inherently well-suited for precise flow control and throttling. When paired with a durable PTFE diaphragm, they provide reliable management of sensitive, viscous, or abrasive fluids without damaging the product or the valve itself.

Understanding the Trade-offs and Considerations

While highly beneficial, PTFE diaphragm valves are not a universal solution. A clear understanding of their context is crucial for proper implementation.

Focus on Total Cost of Ownership

The upfront cost of a high-performance PTFE valve may be higher than that of a valve made from other materials. The decision to use them should be based on the total cost of ownership, where their longevity and reliability create significant long-term savings that outweigh the initial investment.

The Importance of Correct Actuation and Installation

Even the most durable valve can fail prematurely if installed or operated improperly. Ensuring the valve is correctly specified for the process pressures and temperatures and that any automated actuation is properly calibrated is essential to achieving its maximum cycle life.

Not a Replacement for System Design

A high-quality valve is only one component of a well-designed system. It cannot compensate for fundamental flaws in process piping, pumping, or system layout. Its benefits are maximized when it is integrated into a system that is holistically designed for purity and efficiency.

Making the Right Choice for Your Process

Integrating PTFE diaphragm valves is a strategic decision that should align with your primary operational goals.

- If your primary focus is process reliability and uptime: The high cycle life is your greatest asset, ensuring validated processes run without the interruption of frequent valve maintenance.

- If your primary focus is product purity and preventing contamination: PTFE's chemical inertness, coupled with its longevity, minimizes contamination risks from both material leaching and maintenance-induced exposure.

- If your primary focus is long-term cost reduction: The lower total cost of ownership derived from reduced maintenance and fewer replacements makes these valves a sound financial investment.

Ultimately, choosing high-cycle PTFE diaphragm valves is a foundational step toward building a more robust, safe, and efficient pharmaceutical manufacturing operation.

Summary Table:

| Benefit | Impact on Pharmaceutical Manufacturing |

|---|---|

| High Cycle Life | Minimizes process shutdowns for maintenance, reducing downtime. |

| Chemical Inertness | Prevents contamination, protecting product purity and sterility. |

| Lower Total Cost of Ownership | Reduces long-term costs for parts, labor, and lost batches. |

Ready to enhance the reliability and purity of your pharmaceutical processes? KINTEK specializes in manufacturing high-performance, custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact solution you need for superior operational stability. Contact KINTEK today to discuss how our PTFE expertise can benefit your manufacturing line.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What processing methods are typically used for PTFE? Mastering the Unique Path from Powder to Precision Part

- How should Teflon gland packing be maintained? A Guide to Preventing Leaks and Extending Lifespan

- What are the advantages of solid Teflon O-rings? Achieve Unmatched Chemical & Thermal Resistance

- What is the coefficient of friction for PTFE? Mastering Low-Friction Material Selection

- What are the key features of PTFE diaphragms? Maximize Performance in Demanding Applications

- In which applications are EPDM valve seats most suitable? A Guide to Water & Steam Systems

- Why is proper bonding crucial for PTFE sliding bearings? It's the Key to Managing Immense Shear Forces

- What are the key features of PTFE ball valves? Superior Chemical Resistance & Reliable Flow Control