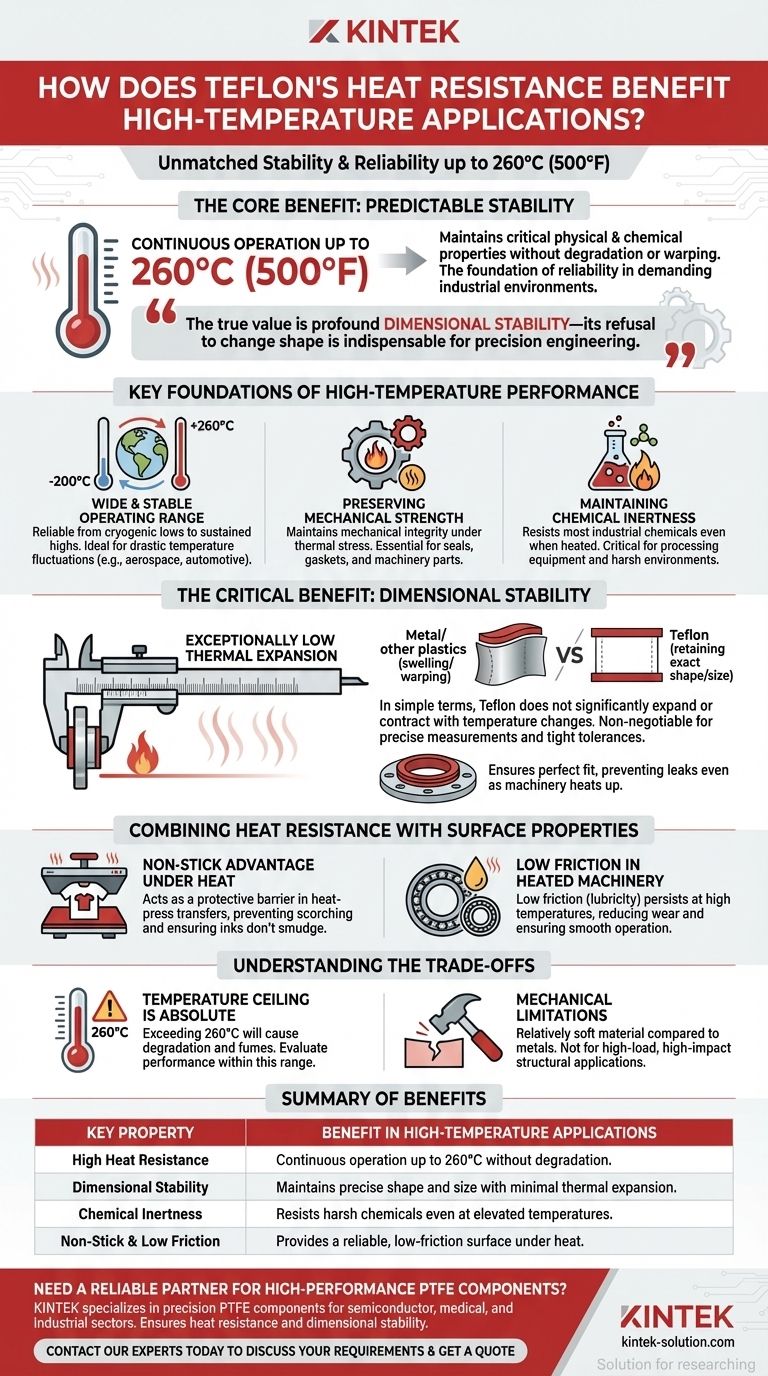

The fundamental benefit of Teflon's heat resistance is its ability to maintain its critical physical and chemical properties at continuous operating temperatures up to 260°C (500°F). This ensures components made from Teflon sheets do not degrade, warp, or fail when exposed to intense heat, providing unmatched stability and reliability in demanding industrial environments.

The true value of Teflon in high-temperature applications isn't just its ability to survive the heat. It's the material's profound dimensional stability—its refusal to change shape or lose its core properties—that makes it indispensable for precision engineering.

The Foundation of High-Temperature Performance

Teflon (PTFE) sheets are engineered to perform reliably where other materials would falter. This capability stems from a unique combination of thermal and chemical resilience.

A Wide and Stable Operating Range

Teflon functions effectively across a vast temperature spectrum, from cryogenic lows of -200°C to sustained highs of +260°C. This makes it exceptionally reliable for applications that experience drastic temperature variations, such as in aerospace or automotive systems.

Preserving Mechanical Strength

Unlike many plastics that soften or deform under heat, Teflon maintains its mechanical integrity. This allows it to be used for critical components like seals, gaskets, and machinery parts that must perform consistently under thermal stress without failing.

Maintaining Chemical Inertness

Teflon's celebrated chemical resistance is not compromised by high temperatures. It remains inert to most industrial chemicals even when heated, a critical feature for processing equipment and components exposed to harsh substances.

The Critical Benefit: Dimensional Stability

The most significant advantage for precision applications is Teflon's exceptionally low coefficient of thermal expansion. This property is central to its role in high-tech industries.

Low Thermal Expansion Explained

In simple terms, Teflon does not significantly expand or contract when its temperature changes. While metals and other plastics may swell or warp with heat, Teflon components hold their exact shape and size.

Impact on Precision Components

This stability is non-negotiable in industries like aerospace and manufacturing, where precise measurements and tight tolerances are paramount. Seals and gaskets made from Teflon continue to provide a perfect fit, preventing leaks even as machinery heats up.

Combining Heat Resistance with Surface Properties

Teflon's heat resistance works in concert with its unique surface characteristics to solve specific manufacturing challenges.

The Non-Stick Advantage Under Heat

In applications like heat-press transfers, a Teflon sheet acts as a protective barrier. Its ability to withstand the heat prevents scorching, while its non-stick surface ensures that inks and adhesives do not smudge or stick to the heating element.

Low Friction in Heated Machinery

Teflon's inherently low friction, or lubricity, also persists at high temperatures. This is vital for moving machinery components that operate in hot environments, reducing wear and ensuring smooth, efficient operation.

Understanding the Trade-offs

While exceptionally capable, Teflon is not a universal solution. Understanding its limitations is key to using it effectively.

The Temperature Ceiling is Absolute

The 260°C (500°F) service temperature is a firm limit. Exceeding this temperature will cause the material to degrade and release fumes. Its performance should always be evaluated within this specified range.

Mechanical Limitations

Although Teflon maintains its properties, it is a relatively soft material compared to metals. It is not suitable for high-load, high-impact structural applications where the primary need is rigidity or hardness.

Making the Right Choice for Your Goal

To leverage Teflon's properties effectively, align your choice with your primary engineering challenge.

- If your primary focus is dimensional stability and precision: Use Teflon for seals, gaskets, and components in environments with fluctuating temperatures where maintaining exact tolerances is critical.

- If your primary focus is surface protection during heat application: Employ Teflon sheets as a reusable, non-stick barrier in processes like heat pressing or industrial baking to protect both the product and the equipment.

- If your primary focus is material reliability in extreme conditions: Choose Teflon for components in aerospace, automotive, or chemical processing that must perform without failure despite exposure to both high heat and aggressive chemicals.

Ultimately, Teflon's value in high-temperature environments comes from its predictable stability, making it a cornerstone material for applications where failure is not an option.

Summary Table:

| Key Property | Benefit in High-Temperature Applications |

|---|---|

| High Heat Resistance | Continuous operation up to 260°C (500°F) without degradation. |

| Dimensional Stability | Maintains precise shape and size with minimal thermal expansion. |

| Chemical Inertness | Resists harsh chemicals even at elevated temperatures. |

| Non-Stick & Low Friction | Provides a reliable, low-friction surface under heat. |

Need a reliable partner for your high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver the critical heat resistance and dimensional stability your applications demand, from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications