In the chemical industry, the corrosion resistance of Teflon (PTFE) gland fillers directly translates to enhanced safety, operational reliability, and reduced maintenance costs. Because Teflon is chemically inert to nearly all acids, bases, and solvents, it maintains its structural integrity and sealing capability without degrading, preventing dangerous leaks and ensuring the longevity of critical equipment like pumps, valves, and storage tanks.

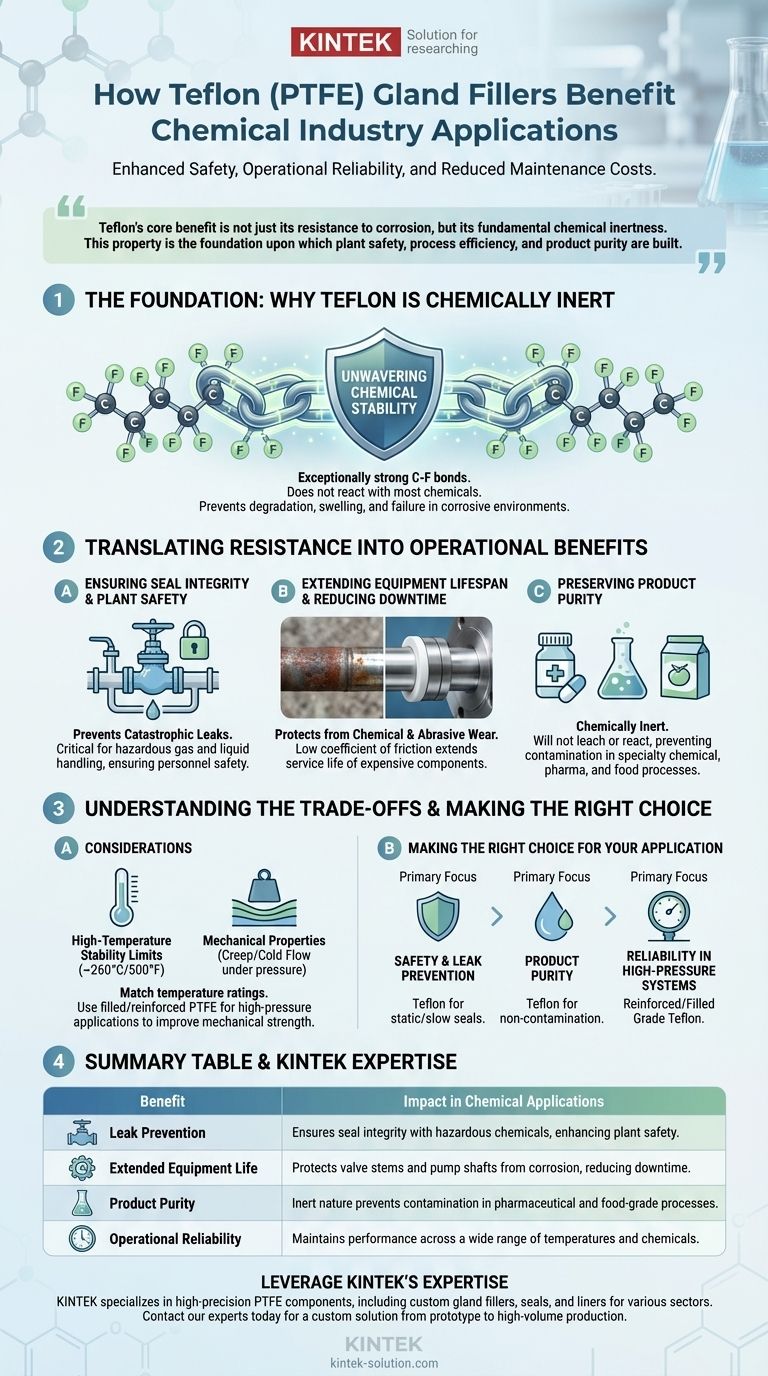

Teflon's core benefit is not just its resistance to corrosion, but its fundamental chemical inertness. This property is the foundation upon which plant safety, process efficiency, and product purity are built in aggressive chemical environments.

The Foundation: Why Teflon is Chemically Inert

Teflon gland fillers are manufactured from Polytetrafluoroethylene (PTFE), a fluoropolymer with unique properties. Its performance is rooted in its molecular structure.

Unwavering Chemical Stability

The bond between carbon and fluorine atoms in the PTFE molecule is exceptionally strong and stable. This powerful bond shields the carbon backbone from chemical attack.

As a result, Teflon fillers do not react with most chemicals. This inertness ensures they function reliably without degrading, swelling, or failing, even when exposed to highly corrosive substances at elevated temperatures.

Translating Resistance into Operational Benefits

This fundamental chemical stability creates a cascade of benefits that are critical for any chemical processing operation.

Ensuring Seal Integrity and Plant Safety

The primary function of a gland filler is to create a seal and prevent leaks. In chemical applications, a leak can be catastrophic, releasing hazardous materials into the environment.

Teflon's resistance ensures the seal remains intact. This is essential in gas handling systems or pipelines for substances like chlorine, where a tight, reliable seal is non-negotiable for preventing harmful gas leaks and ensuring personnel safety.

Extending Equipment Lifespan and Reducing Downtime

When sealing materials corrode, they not only fail but can also damage the equipment they are meant to protect. Aggressive chemicals can attack and degrade metal valve stems or pump shafts.

Because Teflon has a low coefficient of friction and is chemically stable, it protects the surrounding equipment from both chemical and abrasive wear. This extends the service life of expensive components and significantly reduces costly, unplanned maintenance downtime.

Preserving Product Purity

In processes where product purity is critical, any material that reacts with the medium can introduce contamination.

Teflon's inert nature means it will not leach or react with the process fluid. This anti-adhesion property, combined with its common availability in food-grade certifications, makes it an ideal choice for specialty chemical, pharmaceutical, and food processing applications.

Understanding the Trade-offs

While Teflon's chemical resistance is nearly universal, its performance in a specific application depends on a complete understanding of its properties. No material is a perfect solution for every scenario.

High-Temperature Stability Has Limits

Teflon offers excellent performance across a wide temperature range. However, it does have an upper service limit, typically around 260°C (500°F).

For applications that consistently exceed this temperature, the material can begin to degrade. It is crucial to match the material's temperature rating to the system's operational parameters.

Considering Mechanical Properties

Pure, or "virgin," PTFE can be susceptible to creep and cold flow, especially under high mechanical loads or pressures. This means the material can slowly deform over time, potentially compromising the seal.

For high-pressure applications, filled or reinforced grades of PTFE are often used. These combine PTFE with other materials (like glass or carbon) to improve mechanical strength and resistance to creep while retaining excellent chemical compatibility.

Making the Right Choice for Your Application

Selecting the correct gland filler requires matching the material properties to your primary operational goal.

- If your primary focus is safety and leak prevention: Teflon is the default choice for static or slow-moving seals handling nearly any corrosive chemical within its temperature and pressure limits.

- If your primary focus is product purity: Teflon's inertness and anti-adhesion properties make it ideal for preventing contamination in specialty chemical, pharmaceutical, or food-grade processes.

- If your primary focus is reliability in high-pressure systems: Use a reinforced or filled grade of Teflon to gain the necessary mechanical strength and resistance to creep.

By understanding these properties, you can leverage Teflon's exceptional chemical resistance to build safer and more reliable systems.

Summary Table:

| Benefit | Impact in Chemical Applications |

|---|---|

| Leak Prevention | Ensures seal integrity with hazardous chemicals, enhancing plant safety. |

| Extended Equipment Life | Protects valve stems and pump shafts from corrosion, reducing downtime. |

| Product Purity | Inert nature prevents contamination in pharmaceutical and food-grade processes. |

| Operational Reliability | Maintains performance across a wide range of temperatures and chemicals. |

Leverage Teflon's superior chemical resistance in your operations. KINTEK specializes in manufacturing high-precision PTFE components, including custom gland fillers, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get parts that deliver maximum safety, reliability, and longevity. Contact our experts today to discuss your specific application and receive a custom solution from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications