In short, the temperature tolerance of PTFE reducing flanges allows them to maintain their structural integrity, sealing capability, and chemical resistance across an exceptionally wide temperature range. This ensures reliable, safe, and consistent performance in both cryogenic and high-heat industrial applications, something lesser materials cannot guarantee.

The core benefit is not just surviving extreme temperatures, but performing predictably within them. PTFE's thermal stability prevents leaks, material degradation, and flow disruptions that occur when other materials warp, crack, or soften under thermal stress.

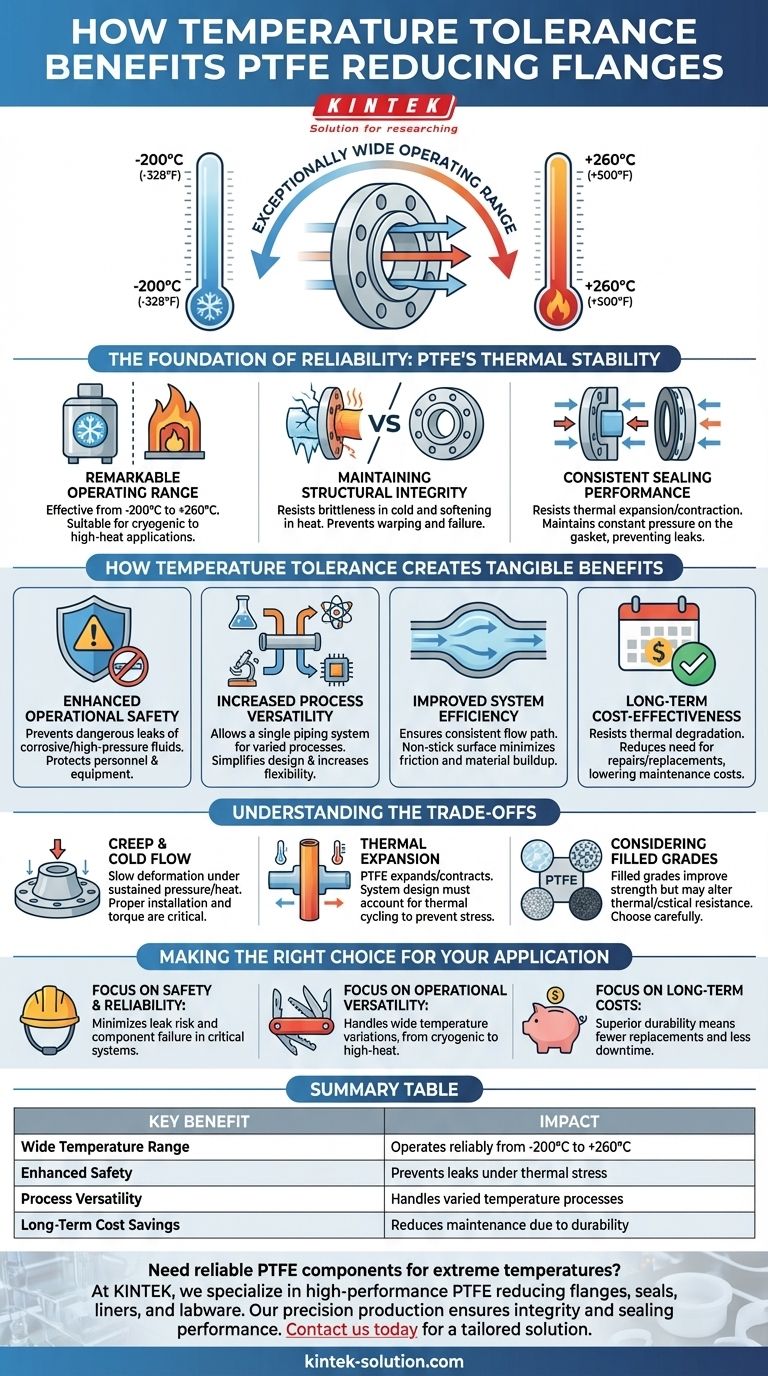

The Foundation of Reliability: PTFE's Thermal Stability

The value of a component like a reducing flange lies in its reliability. PTFE's ability to handle extreme temperatures is the bedrock of that reliability.

A Remarkable Operating Range

PTFE can operate effectively in temperatures ranging from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic fluid transfer to high-temperature chemical processing without failing.

Maintaining Structural Integrity

Unlike many plastics that become brittle and crack in extreme cold or soften and deform in high heat, PTFE maintains its key physical properties.

This stability means the flange will not warp under thermal load, ensuring the integrity of the piping connection and preventing catastrophic failure.

Consistent Sealing Performance

The primary job of a flange is to create a secure, leak-proof seal.

Because PTFE resists thermal expansion and contraction better than many alternatives, it maintains constant pressure on the gasket, preventing leaks even in systems with fluctuating temperatures.

How Temperature Tolerance Creates Tangible Benefits

This inherent thermal stability translates directly into measurable advantages for safety, efficiency, and cost.

Enhanced Operational Safety

Predictable material performance is critical for safety. A flange that does not degrade or fail due to temperature swings prevents dangerous leaks of corrosive chemicals or high-pressure fluids, protecting both personnel and equipment.

Increased Process Versatility

Using PTFE reducing flanges allows a single piping system to be used for a wider variety of processes. This simplifies design, reduces the need for specialized components, and makes your operation more flexible.

Improved System Efficiency

A stable flange ensures a consistent and smooth flow path. Its non-stick surface, which is maintained across the temperature range, minimizes friction and prevents material buildup, reducing the risk of blockages and maintaining productivity.

Long-Term Cost-Effectiveness

PTFE's resistance to thermal degradation means it has a very long service life. This durability significantly reduces the need for frequent repairs and replacements, leading to lower maintenance costs and less operational downtime.

Understanding the Trade-offs

While highly effective, it's important to understand the complete performance profile of PTFE to ensure proper application.

Creep and Cold Flow

Under sustained pressure, especially at higher temperatures, PTFE can be subject to "creep" or "cold flow," a slow, permanent deformation. Proper installation, including correct bolt torque procedures, is critical to mitigate this effect and maintain a long-lasting seal.

Thermal Expansion

Although stable, PTFE still has a coefficient of thermal expansion. In system design, especially for long pipe runs or extreme temperature cycles, engineers must account for this to prevent undue stress on the connections.

Considering Filled Grades

For applications requiring higher mechanical strength, "filled" grades of PTFE exist (e.g., glass-filled or carbon-filled). While these improve rigidity, they may alter the material's thermal or chemical resistance properties, a trade-off that must be considered during selection.

Making the Right Choice for Your Application

Your specific goal will determine which benefit of PTFE's temperature tolerance is most critical.

- If your primary focus is process safety and reliability: The consistent performance of PTFE across its temperature range minimizes the risk of leaks and component failure in critical systems.

- If your primary focus is operational versatility: PTFE flanges allow a single piping system to handle processes with wide temperature variations, from cryogenic to high-heat.

- If your primary focus is reducing long-term costs: The durability and superior resistance to thermal degradation mean fewer replacements and less maintenance downtime over the component's life.

Ultimately, PTFE's exceptional temperature tolerance provides the operational certainty required for the most demanding industrial environments.

Summary Table:

| Key Benefit | Impact |

|---|---|

| Wide Temperature Range | Operates reliably from -200°C to +260°C (-328°F to +500°F) |

| Enhanced Safety | Prevents leaks of corrosive or high-pressure fluids under thermal stress |

| Process Versatility | Allows single piping systems to handle varied temperature processes |

| Long-Term Cost Savings | Reduces maintenance and replacement needs due to superior durability |

Need reliable PTFE components for extreme temperatures?

At KINTEK, we specialize in manufacturing high-performance PTFE reducing flanges, seals, liners, and custom labware for semiconductor, medical, laboratory, and industrial applications. Our precision production ensures your components maintain structural integrity and sealing performance across the widest temperature ranges, enhancing safety and reducing downtime.

Contact us today to discuss your specific requirements—from prototypes to high-volume orders—and let our experts provide a tailored solution for your demanding environment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability