For any chromatographic analysis, temperature stability is a critical factor in choosing a PTFE-coated septum because it directly impacts the integrity of your sample and the accuracy of your results. A septum that cannot withstand the high temperatures of an instrument, such as a Gas Chromatography (GC) inlet, will degrade. This failure compromises the vial's seal, leading to sample evaporation and the introduction of chemical contaminants (leachables) into your analysis.

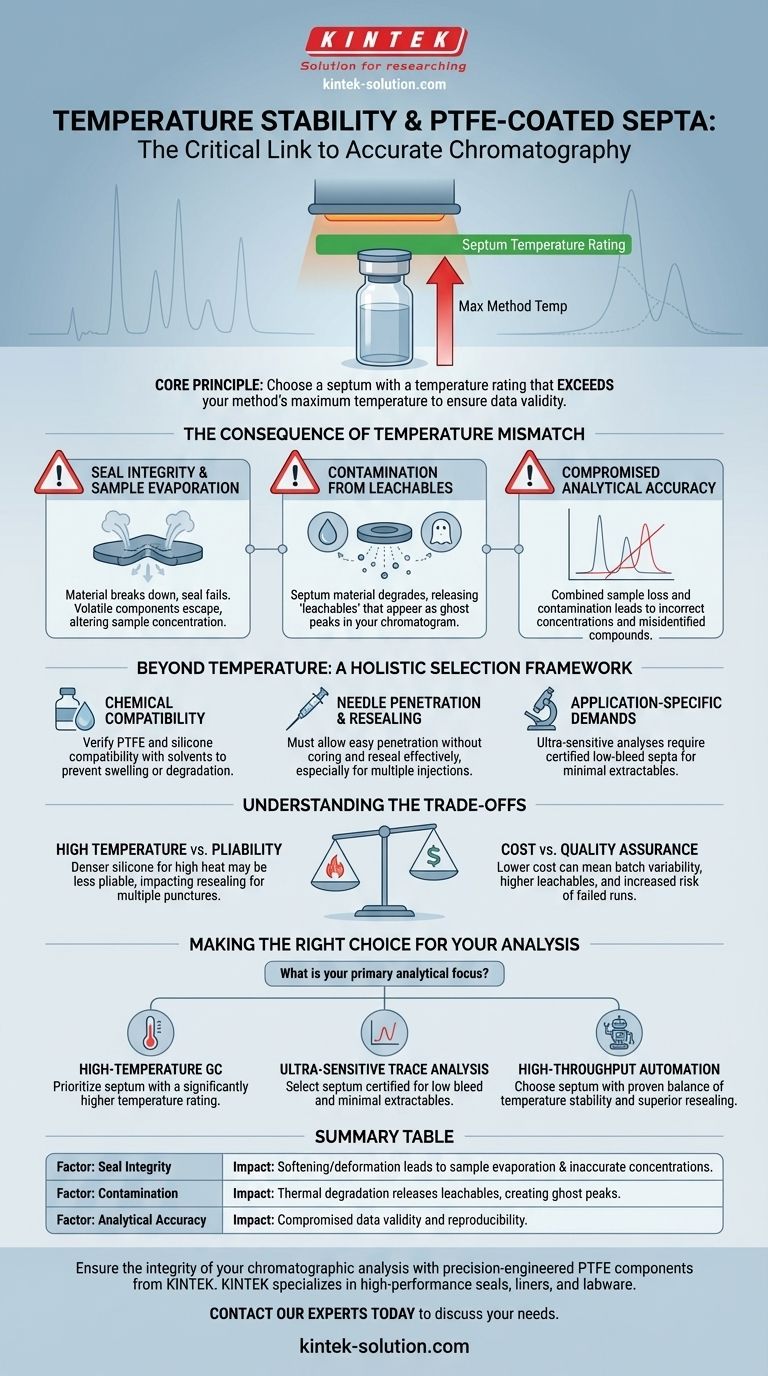

The core principle is simple: You must select a septum with a temperature rating that exceeds the maximum temperature of your analytical method. Failing to do so risks not just a single sample, but the validity of your entire data set.

The Consequence of a Temperature Mismatch

Choosing a septum with an inadequate temperature rating is not a minor oversight; it is a direct path to analytical failure. The consequences manifest in several ways that undermine the goal of accurate, reproducible data.

Seal Integrity and Sample Evaporation

The primary function of a septum is to create an airtight seal. When exposed to heat beyond its limit, the material can soften, deform, or become brittle.

This loss of structural integrity breaks the seal, allowing volatile components of your sample to evaporate and escape the vial, altering the sample's concentration before it is even injected.

Contamination from Leachables

As the septum's material breaks down under thermal stress, it can release its own chemical components, a process known as "leaching" or "bleeding."

These contaminants mix with your sample, appearing as extraneous peaks in your chromatogram. This can interfere with the detection of your target analytes, especially in ultra-sensitive analyses.

Compromised Analytical Accuracy

The combined effects of sample loss and contamination make accurate and reproducible results impossible. Your calculated concentrations will be incorrect, and the presence of ghost peaks from leachables can lead to misidentification of compounds.

Beyond Temperature: A Holistic Selection Framework

While temperature stability is a crucial starting point, it is one piece of a larger puzzle. A truly robust analysis requires considering how the septum interacts with your entire workflow.

Chemical Compatibility

The PTFE coating provides excellent chemical resistance against most acids, bases, and organic solvents.

However, you must always verify that the septum's underlying material (often silicone) is compatible with your specific solvents and sample matrix to prevent swelling, degradation, or interaction.

Needle Penetration and Resealing

A good septum must allow for easy needle penetration without coring (where a piece of the septum is sheared off and deposited in the vial).

Equally important is its ability to reseal effectively after puncture. This is critical for preventing evaporation and is essential in automated systems that may perform multiple injections from the same vial.

Application-Specific Demands

The nature of your analysis dictates specific requirements. For example, ultra-sensitive trace analysis demands septa certified for minimal extractables and leachables to ensure a clean baseline.

Understanding the Trade-offs

Selecting a septum involves balancing competing properties. Understanding these trade-offs is key to making an informed decision rather than simply choosing the most expensive option.

High Temperature vs. Pliability

Septa designed for extremely high temperatures often use a denser silicone formulation. This can make them harder and less pliable, potentially impacting their resealing capability after multiple punctures. You must balance the need for heat resistance with the physical demands of your autosampler.

Cost vs. Quality Assurance

Less expensive septa can be tempting, but they may lack the stringent quality control of reputable manufacturers. This can lead to batch-to-batch variability, higher levels of leachables, and a greater risk of failed analytical runs, ultimately costing more in time and wasted resources.

Making the Right Choice for Your Analysis

Your analytical goal should be the ultimate guide in your selection process. Use your method's parameters to define your septum requirements.

- If your primary focus is High-Temperature GC: Prioritize a septum with a temperature rating significantly above your inlet's maximum temperature to guarantee seal integrity.

- If your primary focus is Ultra-Sensitive Trace Analysis: Select a septum specifically certified by the manufacturer for low bleed and minimal extractables.

- If your primary focus is High-Throughput Automation: Choose a septum that offers a proven balance of temperature stability and superior resealing properties to handle multiple injections.

Ultimately, the right septum is an invisible but foundational component of reliable and accurate chromatographic data.

Summary Table:

| Factor | Impact of Poor Temperature Stability |

|---|---|

| Seal Integrity | Softening/deformation leads to sample evaporation and inaccurate concentrations. |

| Contamination | Thermal degradation releases leachables, creating ghost peaks in chromatograms. |

| Analytical Accuracy | Combined sample loss and contamination compromise data validity and reproducibility. |

Ensure the integrity of your chromatographic analysis with precision-engineered PTFE components from KINTEK.

Choosing the right PTFE-coated septum is critical for preventing sample loss and contamination. KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware designed for the demanding environments of semiconductor, medical, laboratory, and industrial applications.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for temperature stability, chemical compatibility, and resealing performance.

Don't let a faulty septum compromise your data. Contact our experts today to discuss your specific needs and discover how KINTEK's reliable PTFE solutions can enhance your analytical accuracy.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability