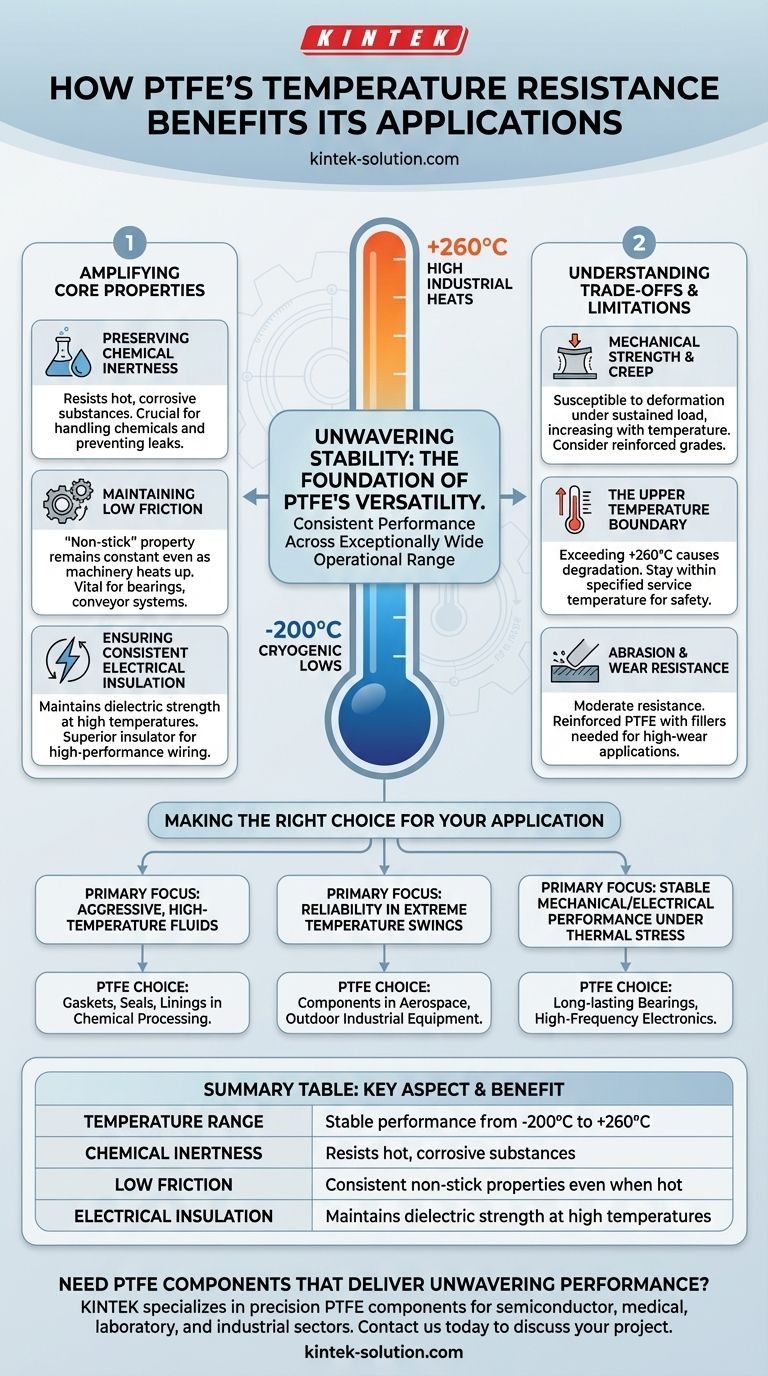

The fundamental benefit of PTFE's temperature resistance is its ability to maintain its other critical properties—such as chemical inertness and low friction—across an exceptionally wide operational range. This stability, from cryogenic lows of -200°C to high industrial heats of +260°C, ensures predictable and reliable performance in environments where other materials would degrade, become brittle, or fail completely.

The true value of PTFE's thermal stability is not just survival in extreme heat or cold. It's the assurance that the material's entire performance profile remains consistent, preventing unexpected failures in critical applications that experience wide temperature fluctuations.

The Foundation of PTFE's Versatility: Unwavering Stability

Polytetrafluoroethylene (PTFE) is defined by its ability to perform reliably under conditions that would compromise most other polymers. This stability is the bedrock upon which its most valuable applications are built.

The Operational Temperature Range

PTFE operates consistently within a vast thermal window, from -200°C (-328°F) to +260°C (500°F). This range covers the majority of industrial, medical, and aerospace engineering requirements.

High-Temperature Performance

At the upper end of its range, PTFE does not melt or lose its structural integrity. This makes it indispensable in high-heat processes like chemical processing, metallurgy, and food production for components like seals, gaskets, and linings.

Cryogenic and Low-Temperature Resilience

Unlike many plastics that become extremely brittle and fracture at low temperatures, PTFE retains its flexibility and durability. This resilience is critical for applications in cryogenics, aerospace, and specialized scientific equipment where extreme cold is a constant.

How Temperature Stability Amplifies Other Core Properties

PTFE’s thermal resistance is a force multiplier. It ensures that its other unique characteristics are available and reliable across its entire operational temperature range, creating a powerful combination of benefits.

Preserving Chemical Inertness

Many chemical reactions accelerate with heat. PTFE’s ability to withstand high temperatures while remaining almost completely chemically inert is crucial for handling hot, corrosive substances. This ensures the integrity of pipes, valves, and container linings, preventing leaks and costly downtime.

Maintaining Low Friction

PTFE is known for having one of the lowest coefficients of friction of any solid. Its thermal stability means this "non-stick" property remains constant even as machinery heats up. This is vital for high-load bearings, conveyor systems, and seals where consistent, low-friction movement is required to prevent seizure and wear.

Ensuring Consistent Electrical Insulation

A material's ability to resist electrical flow can degrade significantly at high temperatures. PTFE maintains its excellent dielectric strength and low electrical conductivity even when hot, making it a superior insulator for high-performance wiring, cables, and electronic components where failure is not an option.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively and safely.

Mechanical Strength and Creep

While thermally stable, PTFE is a relatively soft material. It can be susceptible to "creep," a slow deformation under sustained mechanical load, a tendency that increases at higher temperatures. For high-load structural applications, filled or reinforced grades of PTFE are often required.

The Upper Temperature Boundary

The +260°C limit is for continuous service. Exceeding this temperature can cause the material to degrade and release potentially harmful fumes. Proper engineering controls and staying within the specified service temperature are critical for safety.

Abrasion and Wear Resistance

Standard PTFE has only moderate resistance to abrasion. In applications involving significant mechanical wear, such as high-cycle bearings or scraper blades, it may not be the ideal choice unless it is reinforced with fillers like glass fiber, carbon, or bronze.

Making the Right Choice for Your Application

Selecting PTFE is about leveraging its unique synergy of properties for a specific challenge. Your goal will determine which benefit is most critical.

- If your primary focus is handling aggressive, high-temperature fluids: The combination of extreme chemical inertness and high-heat stability makes PTFE the definitive choice for gaskets, seals, and linings in chemical processing.

- If your primary focus is reliability in extreme temperature swings: PTFE’s consistent performance from cryogenic to hot environments ensures components in aerospace or outdoor industrial equipment will not fail due to thermal shock.

- If your primary focus is stable mechanical or electrical performance under thermal stress: The material's ability to maintain low friction and high insulation at elevated temperatures is crucial for long-lasting bearings and high-frequency electronics.

Ultimately, PTFE's exceptional temperature range provides the operational certainty required for the most demanding engineering challenges.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Temperature Range | Stable performance from -200°C to +260°C |

| Chemical Inertness | Resists hot, corrosive substances |

| Low Friction | Consistent non-stick properties even when hot |

| Electrical Insulation | Maintains dielectric strength at high temperatures |

Need PTFE components that deliver unwavering performance under extreme temperatures?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts maintain critical properties like chemical inertness and low friction across their entire operational range, from cryogenic conditions to high-heat environments.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability for your most demanding applications.

Contact us today to discuss how our PTFE solutions can enhance your project's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application