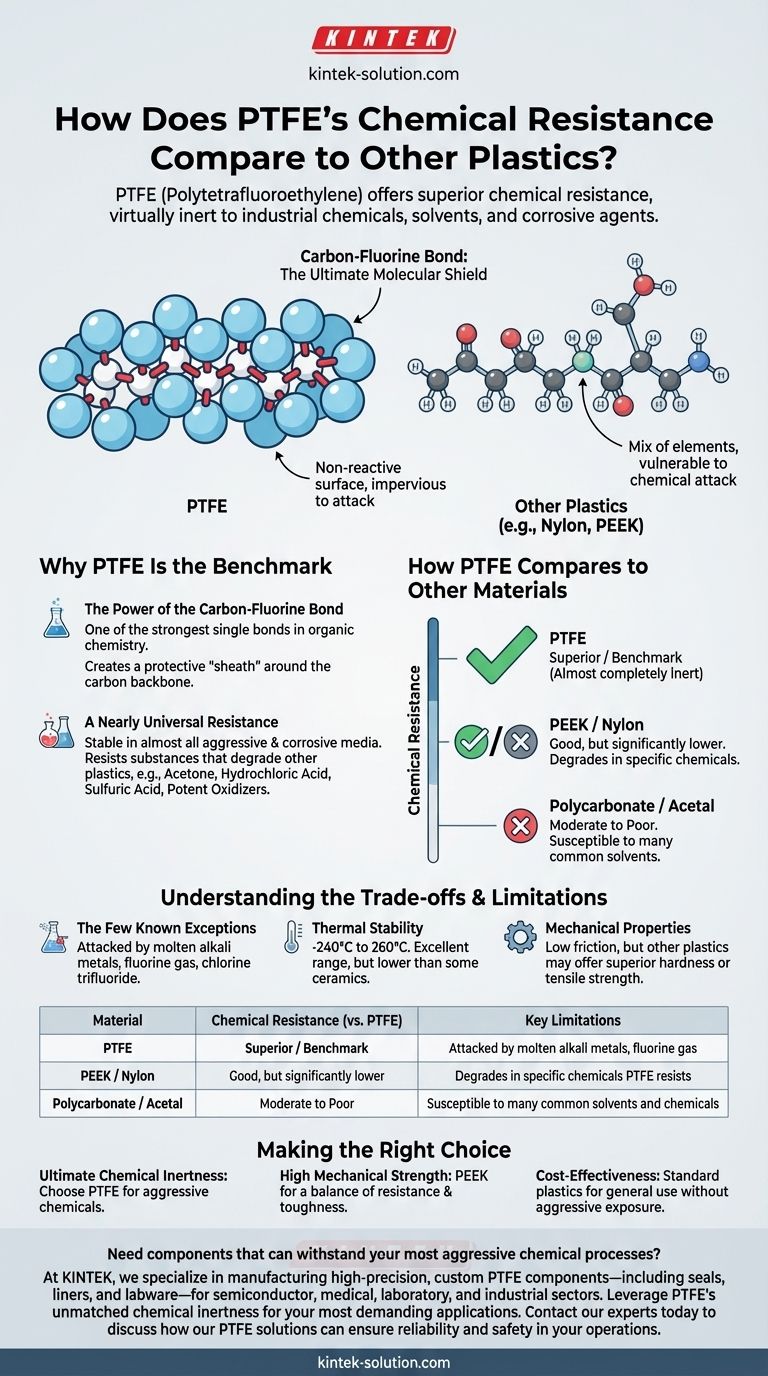

In a direct comparison, PTFE (Polytetrafluoroethylene) offers superior chemical resistance to virtually any other commercially available plastic. Its performance exceeds that of even other high-performance polymers like PEEK and Nylon, making it almost completely inert when exposed to the vast majority of industrial chemicals, solvents, and corrosive agents.

The core reason for PTFE's exceptional performance lies in its unique molecular structure. The incredibly strong and stable bonds between its carbon and fluorine atoms create a non-reactive surface that is nearly impervious to chemical attack.

Why PTFE Is the Benchmark for Chemical Resistance

PTFE's properties are not just a minor improvement over other plastics; they represent a fundamental difference in material composition and performance.

The Power of the Carbon-Fluorine Bond

Unlike most plastics that contain a mix of carbon, hydrogen, and other elements, PTFE is a fluoropolymer composed solely of carbon and fluorine.

The carbon-fluorine bond is one of the strongest single bonds in organic chemistry. This creates a tight, protective "sheath" of fluorine atoms around the carbon backbone of the polymer.

This molecular shield effectively prevents other chemicals from accessing and reacting with the polymer chain, resulting in its characteristic inertness.

A Nearly Universal Resistance

PTFE is stable in almost all aggressive and corrosive media. This includes substances that can easily degrade other plastics, such as acetone, hydrochloric acid, sulfuric acid, and potent oxidizers like sodium peroxide.

This broad-spectrum resistance makes it the default material choice for seals, gaskets, and linings in the most demanding chemical processing environments.

How PTFE Compares to Other Materials

While many plastics offer good resistance to specific chemicals, PTFE provides a level of near-universal inertness that places it in a class of its own.

Against High-Performance Plastics (PEEK, Nylon)

Even advanced engineering plastics known for their durability, like PEEK and Nylon, cannot match PTFE's broad chemical resistance. These materials will degrade when exposed to certain classes of chemicals that have no effect on PTFE.

Against Other Fluoropolymers

PTFE is often considered the gold standard even within its own family of fluoropolymers. While other materials in this class offer excellent properties, PTFE is widely recognized as the most chemically resistant of them all.

Against General Plastics (Polycarbonate, Acetal)

Standard plastics like Polycarbonate and Acetal are susceptible to a wide range of common industrial solvents and chemicals. PTFE's performance is orders of magnitude better, offering reliability where these materials would quickly fail.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE's chemical resistance is nearly absolute, it's crucial to understand its few exceptions and operational boundaries.

The Few Known Exceptions

PTFE is not invincible. It can be attacked by a very specific and limited list of highly reactive substances.

These include molten alkali metals (like sodium), fluorine gas, and other potent fluorinating agents such as chlorine trifluoride. For virtually all other applications, it remains completely inert.

Thermal Stability

PTFE has an exceptionally wide operating temperature range, from approximately -240°C to 260°C (-400°F to 500°F).

However, materials like ceramics can withstand significantly higher temperatures, even if they lack PTFE's chemical inertness and durability.

Mechanical Properties

While PTFE's low coefficient of friction is a significant mechanical advantage for non-stick surfaces and bearings, other plastics may offer superior hardness, tensile strength, or abrasion resistance. The choice of material always depends on the full range of environmental and physical demands.

Making the Right Choice for Your Application

Selecting the correct polymer requires aligning the material's strengths with your primary operational goal.

- If your primary focus is ultimate chemical inertness: PTFE is the definitive choice for handling the most aggressive chemicals, acids, and solvents where material failure is not an option.

- If your primary focus is high mechanical strength in a less extreme chemical environment: A material like PEEK may be a suitable alternative, offering a balance of good chemical resistance and superior physical toughness.

- If your primary focus is cost-effectiveness for general use: Standard plastics are sufficient for applications that do not involve exposure to the aggressive chemicals that demand PTFE's unique properties.

Ultimately, leveraging PTFE's unparalleled chemical stability allows for safe and reliable performance in environments where other materials would inevitably fail.

Summary Table:

| Material | Chemical Resistance (Compared to PTFE) | Key Limitations |

|---|---|---|

| PTFE | Superior / Benchmark | Attacked by molten alkali metals, fluorine gas |

| PEEK / Nylon | Good, but significantly lower | Degrades in specific chemicals PTFE resists |

| Polycarbonate / Acetal | Moderate to Poor | Susceptible to many common solvents and chemicals |

Need components that can withstand your most aggressive chemical processes?

At KINTEK, we specialize in manufacturing high-precision, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Leverage PTFE's unmatched chemical inertness for your most demanding applications, from prototypes to high-volume production.

Contact our experts today to discuss how our PTFE solutions can ensure reliability and safety in your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the applications of polymers in drug delivery systems? Control Release & Improve Efficacy

- What are the different formulations of PTFE available? Find the Right PTFE for Your Application

- What substances can affect the carbon-fluorine bonds of PTFE? The Rare Chemicals That Challenge PTFE

- What makes PTFE a revolutionary material in modern engineering? Unlock Unmatched Chemical & Thermal Resistance

- How is PTFE used in the electrical industry? Unlock Superior Insulation for High-Frequency Applications

- Why is PTFE considered non-reactive? The Power of an Unbreakable Molecular Bond

- What makes PTFE suitable for applications requiring reduced friction? The Ultimate Guide to Low-Friction Performance

- What are the key properties of bronze bushings? Achieve High-Load, Low-Maintenance Performance