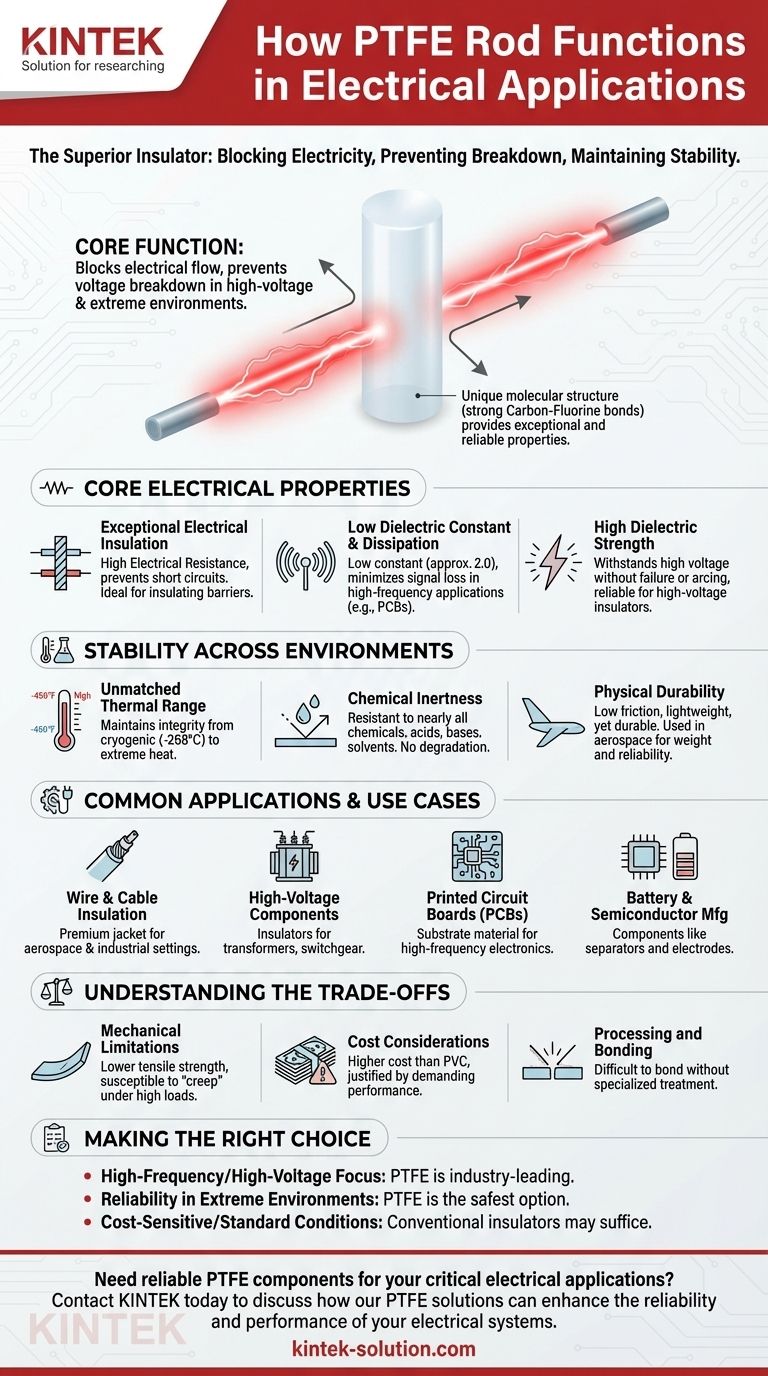

In electrical applications, PTFE rod functions as a superior insulator by blocking the flow of electricity, preventing voltage breakdown in high-voltage environments, and maintaining stable performance across extreme temperatures and harsh chemical conditions. Its unique molecular structure is the source of these exceptional and reliable properties.

The core reason PTFE is trusted for critical electrical components is not just its excellent insulation, but its remarkable consistency. It performs predictably where other materials fail—under extreme heat, cryogenic cold, and chemical attack.

The Core Electrical Properties of PTFE

To understand PTFE's function, we must first examine its fundamental electrical characteristics. These properties are a direct result of its highly symmetric molecular structure, composed of strong carbon-fluorine bonds.

Exceptional Electrical Insulation

PTFE possesses a very high electrical resistance, meaning it strongly opposes the flow of electric current. This makes it an ideal material to separate conductive elements and prevent short circuits.

It is used to create insulating barriers in components like cable jackets, connectors, and transformers.

Low Dielectric Constant and Dissipation

PTFE has a very low dielectric constant (around 2.0) and a low dissipation factor. In simple terms, this means it stores very little electrical energy when exposed to an electric field.

This property is critical for high-frequency applications, such as in printed circuit boards and communication cables, as it minimizes signal loss and distortion.

High Dielectric Strength

Dielectric strength is a measure of an insulator's ability to withstand high voltage without failing or allowing an arc to form. PTFE excels in this area.

Its high resistance to arcing and voltage breakdown makes it a reliable choice for high-voltage insulators and components where electrical integrity is non-negotiable.

Why Stability Across Environments is Critical

An insulator's electrical properties are only useful if they remain stable in the final application's operating environment. This is where PTFE's versatility becomes a significant advantage.

Unmatched Thermal Range

PTFE maintains its integrity and insulating properties over an exceptionally wide temperature range. It remains functional in cryogenic applications as low as -450°F (-268°C).

Simultaneously, it can withstand high temperatures, making it suitable for insulating wires and components near engines or other heat sources in the aerospace and automotive industries.

Chemical Inertness

PTFE is famously resistant to nearly all chemicals, including aggressive acids, bases, and solvents.

This ensures that the material will not degrade or lose its insulating properties when exposed to fuels, lubricants, or other harsh substances, preventing component failure.

Physical Durability

While valued for its electrical properties, PTFE also has a very low coefficient of friction and is lightweight.

This combination of physical durability and electrical performance is why it is used for wire insulation and component coatings on aircraft, where both weight and reliability are paramount.

Common Applications and Use Cases

The unique combination of these properties makes PTFE rod a solution for many demanding electrical and electronic challenges.

Wire and Cable Insulation

PTFE is used as a premium jacket or insulator for wires and cables, especially in aerospace and industrial settings where performance under stress is required.

High-Voltage Components

Due to its high dielectric strength, PTFE is machined into insulators for transformers, capacitors, and other high-voltage switchgear.

Printed Circuit Boards (PCBs)

In high-frequency electronics, PTFE is used as a substrate material for PCBs to ensure signal integrity and minimal energy loss.

Battery and Semiconductor Manufacturing

PTFE's purity and chemical resistance make it suitable for components like battery separators and electrodes, as well as parts used in semiconductor fabrication.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's performance is exceptional, it comes with practical considerations that must be weighed against its benefits.

Mechanical Limitations

PTFE is a relatively soft material with lower tensile strength compared to many engineering plastics. Under high mechanical loads, it can be susceptible to "creep" or cold flow, where the material slowly deforms over time.

Cost Considerations

PTFE is a high-performance polymer, and its cost is significantly higher than that of common insulators like PVC or polyethylene. Its use is typically justified by demanding performance requirements that other materials cannot meet.

Processing and Bonding

PTFE's chemical inertness and non-stick surface make it very difficult to bond to other materials using conventional adhesives. Specialized surface treatments or etching processes are required, adding complexity to manufacturing.

Making the Right Choice for Your Application

Selecting the right insulator depends entirely on the specific demands of your project.

- If your primary focus is high-frequency or high-voltage performance: PTFE is an industry-leading choice due to its low dielectric constant and high dielectric strength.

- If your primary focus is reliability in extreme environments: PTFE's unparalleled thermal range and chemical inertness make it the safest option for critical applications.

- If your project is cost-sensitive with standard operating conditions: A more conventional insulator like polyethylene or PVC may provide sufficient performance at a lower cost.

Ultimately, choosing PTFE is an investment in stability and reliability for applications where electrical failure is not an option.

Summary Table:

| Property | Benefit for Electrical Applications |

|---|---|

| High Electrical Resistance | Excellent insulator, prevents short circuits |

| Low Dielectric Constant | Minimal signal loss in high-frequency electronics |

| High Dielectric Strength | Withstands high voltage without breakdown |

| Wide Thermal Range | Stable performance from -450°F to high temperatures |

| Chemical Inertness | Resists degradation from acids, bases, and solvents |

Need reliable PTFE components for your critical electrical applications?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components deliver unmatched insulation and stability, even in the most extreme environments, from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance the reliability and performance of your electrical systems.

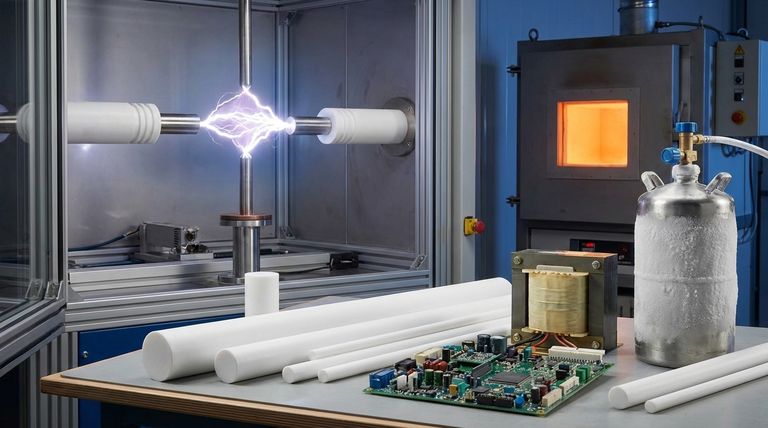

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications