In the demanding thermal environments of aerospace, Polytetrafluoroethylene (PTFE) performs exceptionally well across an extremely wide temperature spectrum. It reliably maintains its core properties from cryogenic lows of approximately -270°C (-450°F) up to a continuous service temperature of 260°C (500°F). This unique thermal stability, combined with its chemical inertness, makes it a foundational material for many critical components.

PTFE’s true value in aerospace is not just its wide operating temperature range, but its ability to retain crucial mechanical properties—like flexibility at cryogenic temperatures and structural integrity at high heat—where other materials would fail.

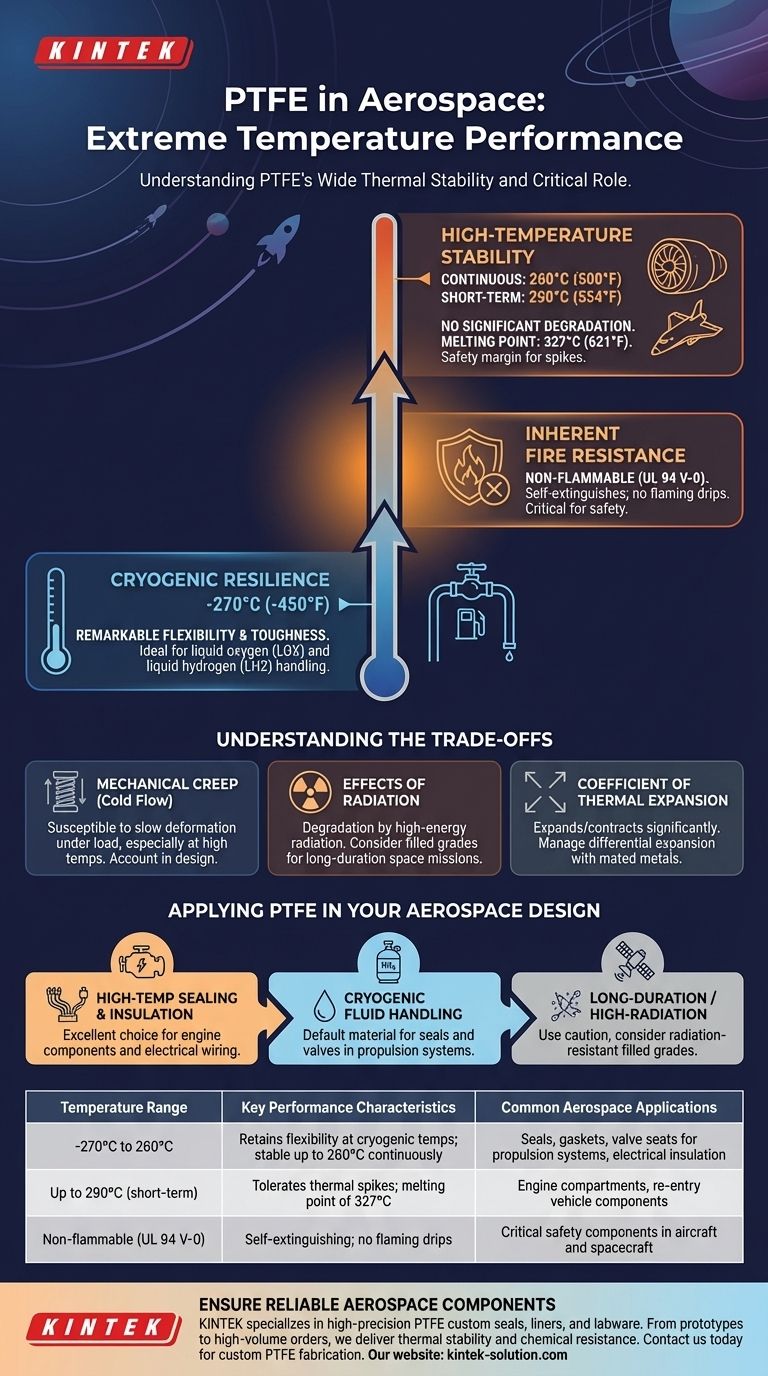

Understanding PTFE's Thermal Performance Envelope

To effectively leverage PTFE, an engineer must understand the specific characteristics it exhibits at both ends of its thermal range. Its performance is not a single data point but a spectrum of behaviors.

High-Temperature Stability

PTFE offers remarkable performance at elevated temperatures. It can be used continuously at 260°C (500°F) without significant thermal degradation.

For short durations, it can even tolerate excursions up to 290°C (554°F). This provides a safety margin for temperature spikes common in engine compartments or during re-entry.

Its high melting point of 327°C (621°F) ensures that it remains in a solid state well above its maximum continuous operating temperature, preventing catastrophic failure.

Cryogenic Resilience

Unlike many polymers that become brittle and fracture at low temperatures, PTFE retains a high degree of flexibility and toughness down to cryogenic levels.

References confirm its viability for applications approaching -270°C (-450°F), making it ideal for handling liquefied gases like liquid oxygen (LOX) or liquid hydrogen (LH2). This property is essential for seals, gaskets, and valve seats in rocket propulsion systems.

Inherent Fire Resistance

Safety is paramount in aerospace design. PTFE is inherently nonflammable, a critical attribute for any material used within aircraft or spacecraft.

It carries a UL 94 V-0 flame rating, which is the highest classification for plastics. This means it self-extinguishes within a very short time after the flame source is removed and does not produce flaming drips.

Understanding the Trade-offs

No material is without its limitations. An objective assessment requires acknowledging the trade-offs associated with PTFE, especially under the combined stresses of aerospace environments.

Mechanical Creep (Cold Flow)

While thermally stable, PTFE is a relatively soft material. Under a constant mechanical load, it can be susceptible to creep, or "cold flow," a slow, continuous deformation.

This effect is more pronounced at higher temperatures. Designers must account for this in applications like high-pressure seals or structural insulators by using filled PTFE grades or incorporating mechanical supports.

Effects of Radiation

For applications in space, radiation exposure is a critical factor. Standard PTFE can be degraded by high-energy radiation, such as that found in the Van Allen belts or during long-duration interplanetary missions.

This radiation can break the carbon-fluorine bonds, reducing the material's mechanical strength and potentially compromising its integrity over the mission's lifetime.

Coefficient of Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes.

In assemblies where PTFE is mated with metal components, this differential expansion must be carefully managed in the design to avoid inducing stress, loss of seal pressure, or mechanical binding.

Applying PTFE in Your Aerospace Design

Your choice to use PTFE should be guided by the primary demands of the specific application.

- If your primary focus is high-temperature sealing and insulation: PTFE is an excellent choice for engine components, electrical wiring, and fluid lines where it will resist melting and chemical degradation.

- If your primary focus is cryogenic fluid handling: Its unmatched flexibility at extreme low temperatures makes it the default material for seals, hoses, and valve components in propulsion and life-support systems.

- If your primary focus is a long-duration mission in a high-radiation environment: Use caution and consider radiation-resistant filled grades of PTFE or alternative materials like PEEK for critical structural components.

Understanding both its remarkable stability and its practical limitations is the key to leveraging PTFE successfully in mission-critical applications.

Summary Table:

| Temperature Range | Key Performance Characteristics | Common Aerospace Applications |

|---|---|---|

| -270°C to 260°C | Retains flexibility at cryogenic temps; stable up to 260°C continuously | Seals, gaskets, valve seats for propulsion systems, electrical insulation |

| Up to 290°C (short-term) | Tolerates thermal spikes; melting point of 327°C | Engine compartments, re-entry vehicle components |

| Non-flammable (UL 94 V-0) | Self-extinguishing; no flaming drips | Critical safety components in aircraft and spacecraft |

Ensure your aerospace components perform reliably under extreme thermal conditions. KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the thermal stability and chemical resistance your mission demands.

Contact us today to discuss your specific requirements and leverage our expertise in custom PTFE fabrication.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts