In short, Polytetrafluoroethylene (PTFE) performs exceptionally well in extreme aerospace conditions. Its reliability stems from a unique combination of properties, most notably an extremely wide operational temperature range, inherent non-flammability, and stability in the vacuum of space. This makes it a critical material for seals, gaskets, insulation, and coatings where other polymers would fail.

PTFE's value in aerospace is not just its resistance to heat or cold, but its predictable performance across a vast spectrum of hostile environments. Its suitability hinges on a combination of thermal stability, chemical inertness, and low outgassing, making it a default choice for many non-structural, mission-critical components.

Unpacking PTFE's Thermal Resilience

A material's ability to maintain its properties at temperature extremes is paramount in aerospace, from the heat of atmospheric re-entry to the deep cold of space. PTFE excels in both domains.

Performance at Extreme High Temperatures

PTFE has outstanding thermal stability. It can be used continuously at temperatures up to 260°C (500°F) without significant chemical degradation.

Its melting point is even higher, around 327°C (621°F). This provides a significant safety margin for applications involving high-energy systems or proximity to engines.

Reliability in Cryogenic Conditions

Unlike many materials that become brittle and fracture at low temperatures, PTFE retains its flexibility.

It is reliably used in cryogenic applications with operational temperatures as low as -200°C (-328°F), and some data shows it remains useful even lower. This makes it ideal for handling liquefied gases and for components exposed to the cold of deep space.

Why PTFE Excels Beyond the Atmosphere

The aerospace environment isn't just about temperature; it's also about the vacuum of space and exposure to harsh environmental factors.

Stability in a Vacuum

A critical property for space applications is low outgassing. This means the material does not release trapped gases when exposed to a vacuum, which is vital to prevent contamination of sensitive optics, sensors, and other nearby components.

Resistance to Environmental Factors

PTFE is highly resistant to weathering and degradation from environmental contaminants. Its properties do not change significantly even after long-term exposure, giving it a long and predictable shelf life for both aircraft and spacecraft components.

Inherent Non-Flammability

Safety is the primary concern in any aerospace design. PTFE is inherently non-flammable, with a UL 94 V-0 flame rating. This means it will self-extinguish almost immediately after a flame source is removed, a critical property for use inside crewed vehicles or near volatile systems.

Understanding the Trade-offs and Limitations

No material is perfect. While PTFE is incredibly capable, a trusted advisor must also point out its limitations to ensure proper application.

Not a Structural Material

PTFE is a relatively soft material. It is susceptible to creep, meaning it can deform slowly over time when under a sustained load. It is not suitable for primary structural components that bear significant mechanical stress.

Susceptibility to Contamination

While chemically inert, PTFE's surface can absorb or embed small particles. In high-precision mechanical systems, this can be a drawback, and designs may require seals or wipers to prevent the accumulation of dirt and debris.

Radiation Sensitivity

Standard grades of PTFE have poor resistance to high-energy radiation, such as that found in space. Radiation exposure can break down the polymer chains, causing the material to become brittle and lose its mechanical properties. For applications in high-radiation environments, special grades or alternative materials must be considered.

Making the Right Choice for Your Application

Selecting PTFE requires aligning its specific strengths with your primary design goal.

- If your primary focus is sealing systems for extreme temperatures: PTFE is an excellent first choice for gaskets and seals in both cryogenic fuel lines and high-temperature fluid systems.

- If your application involves low-friction moving parts in a vacuum: Use PTFE for its low outgassing and self-lubricating properties, but be sure to design for its low structural strength.

- If the component will be exposed to significant radiation: You must evaluate radiation-hardened materials or specifically engineered PTFE grades, as standard PTFE will likely not meet mission lifetime requirements.

By understanding both its profound strengths and its distinct limitations, you can leverage PTFE to achieve exceptional reliability in the most demanding aerospace designs.

Summary Table:

| Property | Performance in Aerospace | Key Limitation |

|---|---|---|

| Temperature Range | -200°C to +260°C (-328°F to +500°F) | Not a structural material (susceptible to creep) |

| Vacuum Stability | Extremely low outgassing, ideal for space | Standard grades have poor radiation resistance |

| Flame Resistance | UL 94 V-0 rating, self-extinguishing | Surface can be susceptible to contamination |

| Chemical Resistance | Highly inert, resistant to weathering and fuels |

Need high-performance PTFE components for your demanding application?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, gaskets, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures your components meet the rigorous standards of aerospace and other extreme environments.

Contact our engineering team today to discuss how our custom PTFE solutions can enhance the reliability and performance of your critical systems.

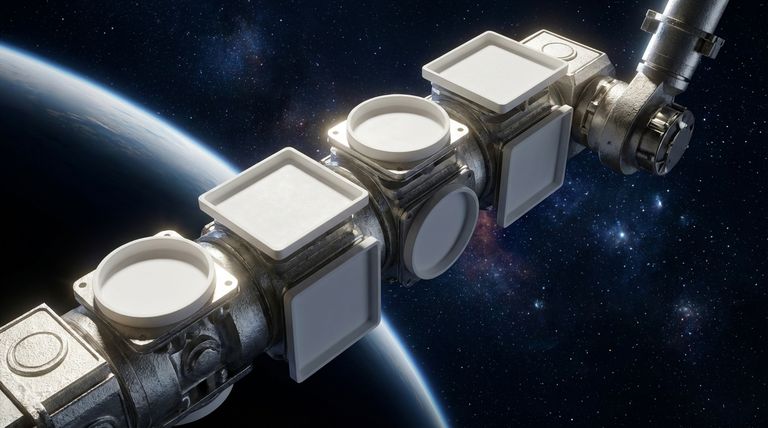

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection