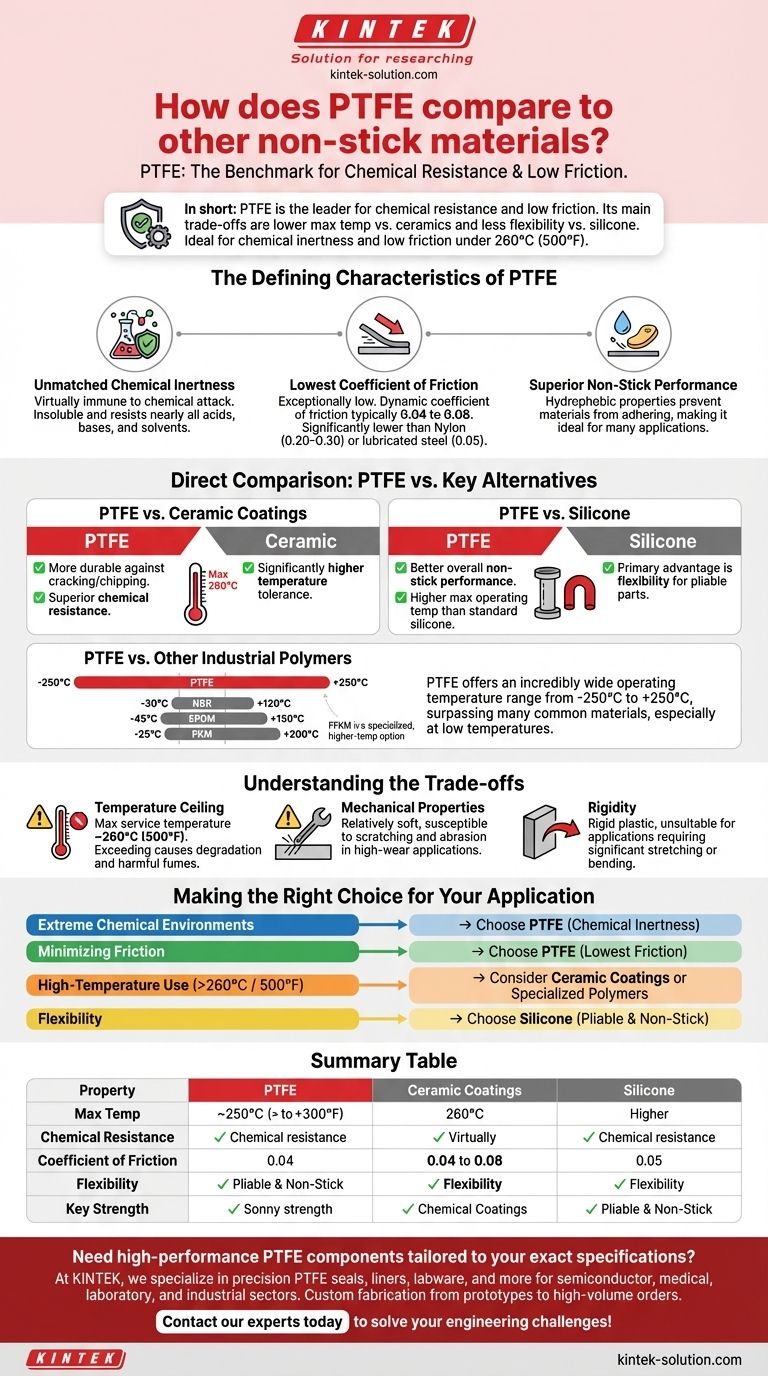

In short, Polytetrafluoroethylene (PTFE) is the benchmark for non-stick materials when it comes to chemical resistance and low friction. It outperforms nearly every alternative in these two categories. Its primary trade-offs are a lower maximum temperature tolerance compared to ceramic coatings and less flexibility compared to silicone.

The decision to use PTFE over another material is not about finding the "best" overall option, but about matching a specific engineering need. PTFE is the definitive choice for applications demanding extreme chemical inertness and the lowest possible friction, as long as operating temperatures remain below 260°C (500°F).

The Defining Characteristics of PTFE

To understand how PTFE compares to other materials, it's essential to first recognize its three defining properties. These characteristics are rooted in its unique molecular structure, which features strong carbon-fluorine bonds.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack. It is highly insoluble and resists nearly all acids, bases, and organic solvents, making it the ideal choice for use in corrosive environments or for handling reactive chemicals.

Only a few highly specialized chemicals under extreme conditions can affect it.

The Lowest Coefficient of Friction

PTFE possesses an exceptionally low coefficient of friction, lower than any other solid engineering material. Its dynamic coefficient of friction typically ranges from 0.04 to 0.08.

This is significantly lower than other common polymers like Nylon (0.20–0.30) or even lubricated steel (0.05), making PTFE the standard for applications where minimizing surface friction is critical.

Superior Non-Stick Performance

This low friction is directly responsible for PTFE's famous non-stick or "hydrophobic" properties. Materials struggle to adhere to its surface, which is why it is so widely used in applications from cookware to industrial molds.

Direct Comparison: PTFE vs. Key Alternatives

Each alternative material presents a different set of trade-offs when measured against PTFE's baseline performance.

PTFE vs. Ceramic Coatings

Ceramic coatings can withstand significantly higher temperatures than PTFE, making them suitable for high-heat applications where PTFE would begin to degrade.

However, PTFE is generally more durable in terms of resisting cracking or chipping and offers superior chemical resistance.

PTFE vs. Silicone

Silicone's primary advantage is its flexibility. For applications requiring a non-stick surface on a pliable or deformable part, silicone is often the better choice.

PTFE, on the other hand, provides better overall non-stick performance and a higher maximum operating temperature than most standard silicone formulations.

PTFE vs. Other Industrial Polymers

When compared to other polymers used in industrial seals and O-rings, PTFE's incredibly wide operating temperature range stands out.

PTFE is stable from -250°C to +250°C. This surpasses the ranges of common materials like NBR (-30°C to +120°C), EPDM (-45°C to +150°C), and FKM (-25°C to +200°C). While specialized materials like FFKM can exceed PTFE's upper limit (up to 340°C), they cannot match its performance at extremely low temperatures.

Understanding the Trade-offs

No material is perfect for every situation. Acknowledging PTFE's limitations is key to using it effectively.

The Temperature Ceiling

The most critical limitation of PTFE is its maximum service temperature of approximately 260°C (500°F). Exceeding this temperature will cause the material to degrade, releasing potentially harmful fumes and losing its structural integrity.

Mechanical Properties

While more durable than brittle ceramics, PTFE is a relatively soft material. It can be susceptible to scratching and abrasion, which may not make it suitable for high-wear mechanical applications without reinforcement.

Rigidity

Compared to elastomers like silicone, PTFE is a rigid plastic. This makes it unsuitable for applications that require the material to stretch or bend significantly during operation.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important requirement of your project.

- If your primary focus is extreme chemical environments: PTFE is the superior choice due to its near-total chemical inertness.

- If your primary focus is minimizing friction: For applications like bearings or sliding surfaces, PTFE is the undisputed benchmark material.

- If your primary focus is high-temperature use (above 260°C / 500°F): You must consider alternatives like ceramic coatings or specialized high-temperature polymers.

- If your primary focus is flexibility: Silicone provides a reliable non-stick surface on a material that can bend and deform.

By understanding these core trade-offs, you can confidently select the material whose properties precisely match your engineering goals.

Summary Table:

| Property | PTFE | Ceramic Coatings | Silicone |

|---|---|---|---|

| Max Temp | 260°C (500°F) | Higher | Lower (typically) |

| Chemical Resistance | Excellent | Good | Good |

| Coefficient of Friction | Very Low (0.04-0.08) | Low | Moderate |

| Flexibility | Rigid | Rigid/Brittle | Flexible |

| Key Strength | Chemical Inertness | High-Temp Use | Flexibility |

Need high-performance PTFE components tailored to your exact specifications?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get the perfect non-stick solution, from prototypes to high-volume orders.

Contact our experts today to discuss how our PTFE components can solve your unique engineering challenges!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What are the additional properties of PTFE? Beyond Non-Stick: Extreme Chemical, Thermal & Electrical Performance

- What are the similarities between PTFE and RPTFE? Unlocking the Core Fluoropolymer Identity