Choosing a PCB material is a foundational decision that directly dictates both manufacturing feasibility and final cost. The material's price per sheet is only the beginning; its properties influence processing complexity, fabrication yields, and even supply chain stability, creating a ripple effect across your entire project budget and timeline.

Your material choice is not just an electrical engineering decision; it is a manufacturing and supply chain strategy. The lowest-cost project is often the result of selecting a material that balances ideal performance with practical manufacturability and availability, not just the one with the cheapest raw cost.

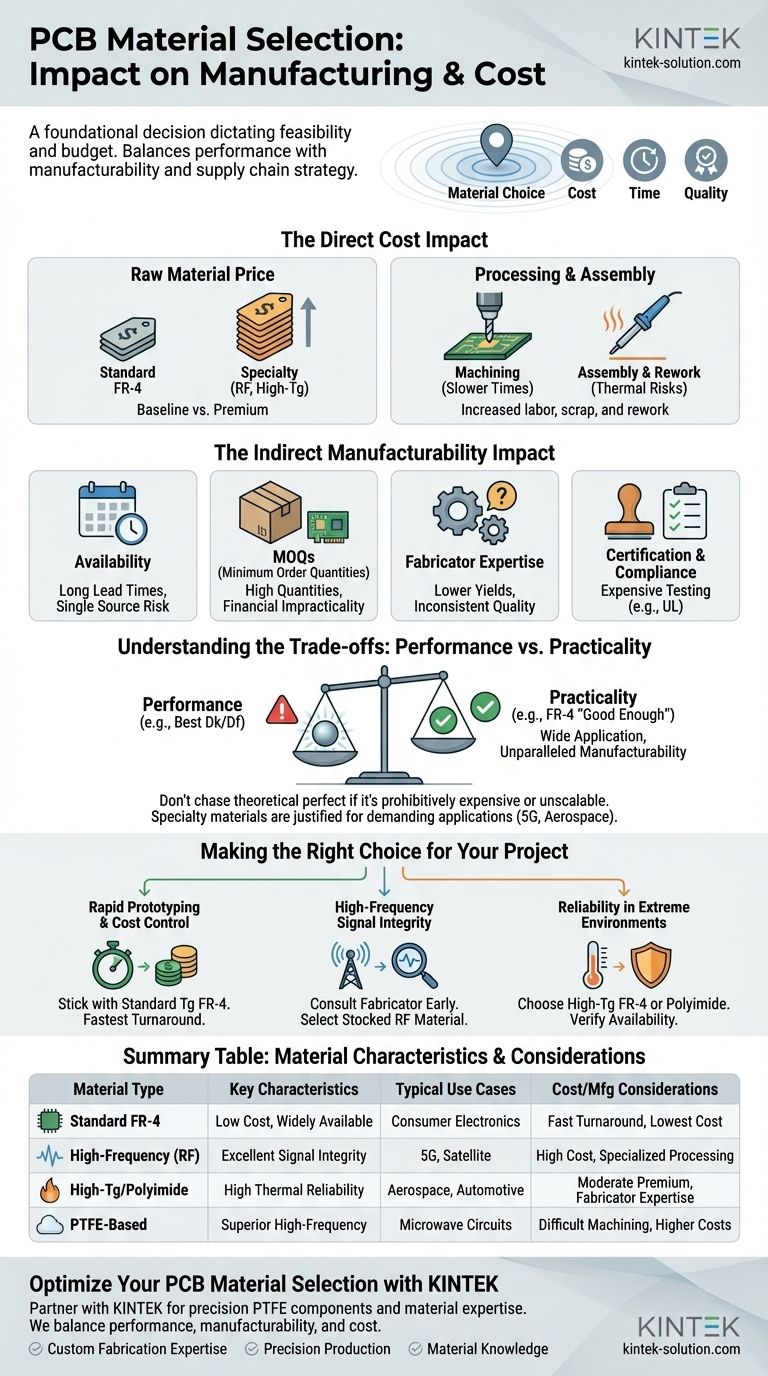

The Direct Impact on Cost

The price tag of the raw laminate is the most obvious cost, but it's often not the most significant. The manufacturing process itself is where costs can escalate unexpectedly.

Raw Material Price

This is the baseline. Standard FR-4 is the industry workhorse due to its low cost and widespread availability. Materials designed for specific performance, like high-frequency (RF) laminates (e.g., Rogers, Taconic) or high-temperature materials (e.g., high-Tg FR-4, Polyimide), carry a significant price premium.

Processing and Machining

Specialty materials are often harder to work with than FR-4. For example, soft PTFE-based materials used in RF circuits can smear during drilling, requiring specialized techniques. This translates directly to increased labor, slower machine times, and higher fabrication costs per board.

Assembly and Rework

A material's thermal properties affect how it behaves during soldering. A material with a low Glass Transition Temperature (Tg) may become unstable during reflow, increasing the risk of assembly defects. This leads to higher scrap rates or costly rework, directly impacting your bottom line.

The Indirect Impact on Manufacturability

A material that looks perfect on a datasheet can become a liability if it introduces friction into the manufacturing process. These "hidden" factors are critical to consider.

Material Availability

Standard FR-4 is a commodity, stocked by nearly every fabricator worldwide. Specialty laminates, however, may have long lead times or be produced by only a few suppliers, introducing significant risk and potential delays to your schedule.

Minimum Order Quantities (MOQs)

Your fabricator may not keep your chosen specialty material in stock. They will have to special order it, often imposing a large minimum order quantity that is financially impractical for prototypes or small production runs.

Fabricator Expertise

Not all PCB shops are equipped to handle all materials. Choosing a laminate your fabricator is unfamiliar with can lead to lower yields, inconsistent quality, and troubleshooting delays. Always confirm your manufacturer's experience with your desired material.

Certification and Compliance

Using a non-standard material may require your final product to undergo expensive and time-consuming regulatory testing, such as UL certification. Standard, pre-certified materials streamline this process, saving both time and money.

Understanding the Trade-offs: Performance vs. Practicality

The central challenge is balancing the engineering requirements of the design with the physical and financial realities of production.

The Myth of the Perfect Datasheet

Engineers can be tempted to select a material with the absolute best dielectric constant (Dk) or loss tangent (Df). However, this theoretical performance is meaningless if the material is prohibitively expensive or cannot be reliably manufactured at scale.

The Value of "Good Enough"

FR-4 remains dominant because it is "good enough" for a vast range of applications. Its electrical performance is adequate for most digital and lower-frequency analog circuits, while its manufacturability is unparalleled.

When Specialty Materials Are Necessary

For demanding applications, the high cost is justified. High-frequency circuits for 5G or satellite communications absolutely require low-loss RF materials. Likewise, aerospace or automotive electronics operating in extreme heat demand the reliability of high-Tg or polyimide substrates.

Making the Right Choice for Your Project

To select the right material, you must first define your project's most critical priority.

- If your primary focus is rapid prototyping and cost control: Stick with a standard Tg FR-4. It guarantees the fastest turnaround times, lowest cost, and widest choice of manufacturing partners.

- If your primary focus is high-frequency signal integrity: Consult with your fabricator before finalizing your design to select a specific Rogers or similar RF material that they have in stock and are experienced in processing.

- If your primary focus is reliability in extreme environments: Choose a high-Tg FR-4 (Tg > 170°C) or Polyimide, but verify its availability and lead time with your supplier early in the design cycle.

A strategic material choice successfully balances datasheet specifications with the practical realities of your supply chain, budget, and timeline.

Summary Table:

| Material Type | Key Characteristics | Typical Use Cases | Key Cost/Manufacturing Considerations |

|---|---|---|---|

| Standard FR-4 | Low cost, widely available, good for most digital/low-frequency analog | Consumer electronics, industrial controls | Fastest turnaround, lowest cost, highest fabricator availability |

| High-Frequency (RF) Laminates | Excellent signal integrity, low loss tangent | 5G, satellite communications, RF circuits | High material cost, specialized processing, potential lead times |

| High-Tg/Polyimide | High thermal reliability, stable in extreme heat | Aerospace, automotive, high-temperature environments | Moderate price premium, requires fabricator expertise, longer lead times |

| PTFE-Based Materials | Superior high-frequency performance, soft substrate | Microwave circuits, RF applications | Difficult machining, specialized drilling techniques, higher fabrication costs |

Optimize Your PCB Material Selection with KINTEK

Struggling to balance performance requirements with manufacturing feasibility and budget constraints? The right material choice is critical, but so is working with a partner who understands both the electrical and production sides of the equation.

KINTEK manufactures precision PTFE components — including seals, liners, and custom labware — for demanding applications in semiconductor, medical, laboratory, and industrial sectors. We understand the critical role material properties play in your final product's performance and manufacturability.

How We Help You Succeed:

- Custom Fabrication Expertise: From initial prototypes to high-volume production, we tailor solutions to your specific material and performance requirements.

- Precision Production: We prioritize manufacturing tolerances and consistency to ensure reliable performance in your most demanding applications.

- Material Knowledge: Our experience with specialized materials like PTFE helps you avoid common manufacturing pitfalls and optimize your design for production.

Let's discuss how the right material and manufacturing partner can streamline your project timeline and control costs. Contact our team today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials