In short, carbon filler fundamentally transforms PTFE from a soft, compliant material into a robust, high-performance engineering plastic. It dramatically improves compressive strength, wear resistance, and its ability to dissipate heat, making it suitable for demanding mechanical applications where virgin PTFE would quickly fail.

The core function of carbon filler is to provide a rigid internal skeleton for the soft PTFE matrix. This reinforcement prevents deformation under load and protects the material from wear, all while creating a pathway for damaging heat to escape.

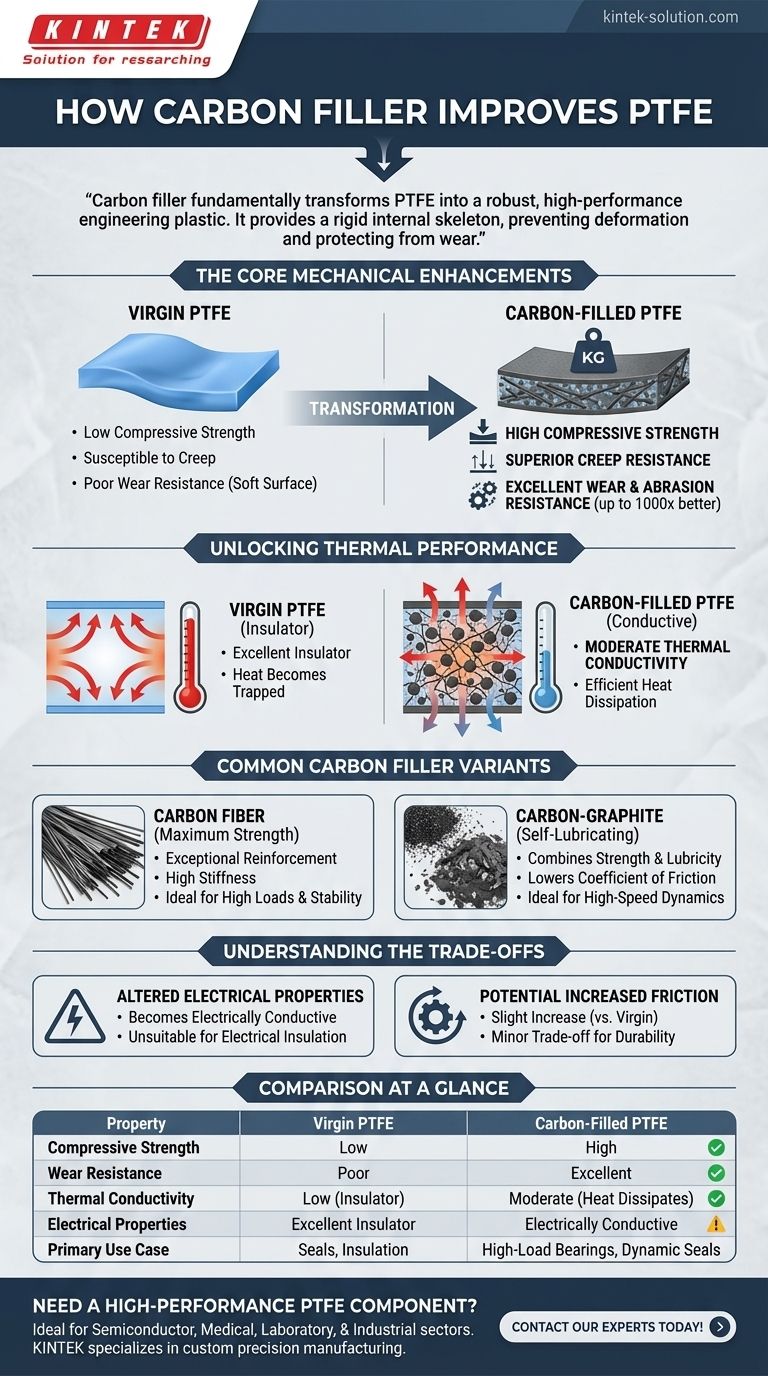

The Core Mechanical Enhancements

Adding carbon to Polytetrafluoroethylene (PTFE) creates a composite material with mechanical properties far superior to the unfilled polymer. This is not a minor adjustment; it is a fundamental shift in the material's performance profile.

Increased Compressive Strength and Creep Resistance

Virgin PTFE is susceptible to creep, which is the tendency to slowly deform under a constant load. Carbon particles or fibers act as a load-bearing reinforcement within the material.

This reinforcement drastically reduces creep and increases compressive strength, ensuring the component maintains its intended shape and tolerances over its service life, especially in sealing or bearing applications.

Superior Wear and Abrasion Resistance

The addition of a hard filler like carbon can increase the abrasion resistance of PTFE by a factor of up to 1,000.

In dynamic applications, the carbon particles protect the softer PTFE from being worn away by contact with other surfaces. This results in significantly longer-lasting seals, rings, and bearings.

Unlocking Thermal Performance

One of the most critical improvements offered by carbon filler is in thermal management, a key weakness of unfilled PTFE.

Enhanced Thermal Conductivity

PTFE is an excellent thermal insulator. In high-speed or high-load applications, friction generates heat that becomes trapped, which can lead to premature failure.

Carbon is thermally conductive. It creates a network within the PTFE that allows this heat to be drawn away from the critical wear surface, roughly doubling the material's overall thermal conductivity and preserving its mechanical integrity.

Common Carbon Filler Variants

Not all carbon fillers are the same. The form of the carbon additive is chosen to optimize the material for a specific set of performance requirements.

Carbon Fiber for Maximum Strength

When the primary need is for mechanical strength, creep resistance, and durability, carbon fiber is the preferred filler. Its long, fibrous structure provides exceptional reinforcement and stiffness.

Carbon-Graphite for Self-Lubrication

For applications like compressor piston rings and rider rings, a carbon-graphite blend is often used. This combines the strength of carbon with the natural lubricity of graphite.

This formulation provides excellent wear resistance while also lowering the coefficient of friction, which is ideal for high-speed, dynamic sealing applications.

Understanding the Trade-offs

While carbon filler provides immense benefits, it also introduces critical trade-offs that must be considered during material selection.

Altered Electrical Properties

Virgin PTFE is one of the best electrical insulators available. Carbon is electrically conductive.

The addition of carbon filler makes the entire composite conductive, rendering it completely unsuitable for any application that requires electrical insulation or high dielectric strength.

Potential for Increased Friction

While it seems counterintuitive, fillers can sometimes slightly increase the coefficient of friction compared to the slippery surface of virgin PTFE.

However, this is a minor trade-off for the massive gains in wear life and load-bearing capacity. For low-friction needs, a carbon-graphite blend is a better choice.

Making the Right Choice for Your Application

Selecting the correct material grade is essential for success. Your decision should be guided by the primary demands of your application.

- If your primary focus is high loads and dimensional stability: Choose a carbon fiber-filled PTFE for its superior compressive strength and creep resistance.

- If your primary focus is high-speed dynamic sealing: Select a carbon-graphite blend to benefit from both wear resistance and self-lubricating properties.

- If your primary focus is electrical insulation: You must avoid carbon-filled grades and use virgin PTFE or a formulation with a non-conductive filler like glass.

By understanding these principles, you can confidently specify a carbon-filled PTFE for demanding mechanical systems that require performance far beyond the limits of the base polymer.

Summary Table:

| Property | Virgin PTFE | Carbon-Filled PTFE |

|---|---|---|

| Compressive Strength | Low | High |

| Wear/Abrasion Resistance | Poor | Excellent (up to 1000x better) |

| Thermal Conductivity | Low (Insulator) | Moderate (Heat can dissipate) |

| Electrical Properties | Excellent Insulator | Electrically Conductive |

| Primary Use Case | Seals, Electrical Insulation | High-Load Bearings, Dynamic Seals, Piston Rings |

Need a High-Performance PTFE Component?

Carbon-filled PTFE is ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors where strength, wear resistance, and thermal management are critical.

KINTEK specializes in the precision manufacturing of custom PTFE components. Whether you need carbon fiber-filled PTFE for maximum strength or a carbon-graphite blend for self-lubrication, we provide custom fabrication from prototypes to high-volume orders.

Let us help you select the right material and manufacture a component that exceeds your performance requirements.

Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE used in the semiconductor industry? For Unmatched Chemical Resistance and Purity

- What advantages do extruded PTFE rods offer? Superior Durability for High-Stress Applications

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- Why is the PTFE ball valve considered a popular choice in various industries? Unmatched Reliability in Demanding Environments

- What are the benefits of PTFE's low friction coefficient in shaft seals? Boost Efficiency & Extend Equipment Life

- How does PTFE paste extrusion work? A Guide to Manufacturing High-Strength Components

- Why is surface treatment necessary for PTFE sheets used in tank linings? Ensuring a Secure and Reliable Bond

- Why does the spring PTFE sealing ring maintain effective sealing across its working pressure range? Discover the Engineering Secret