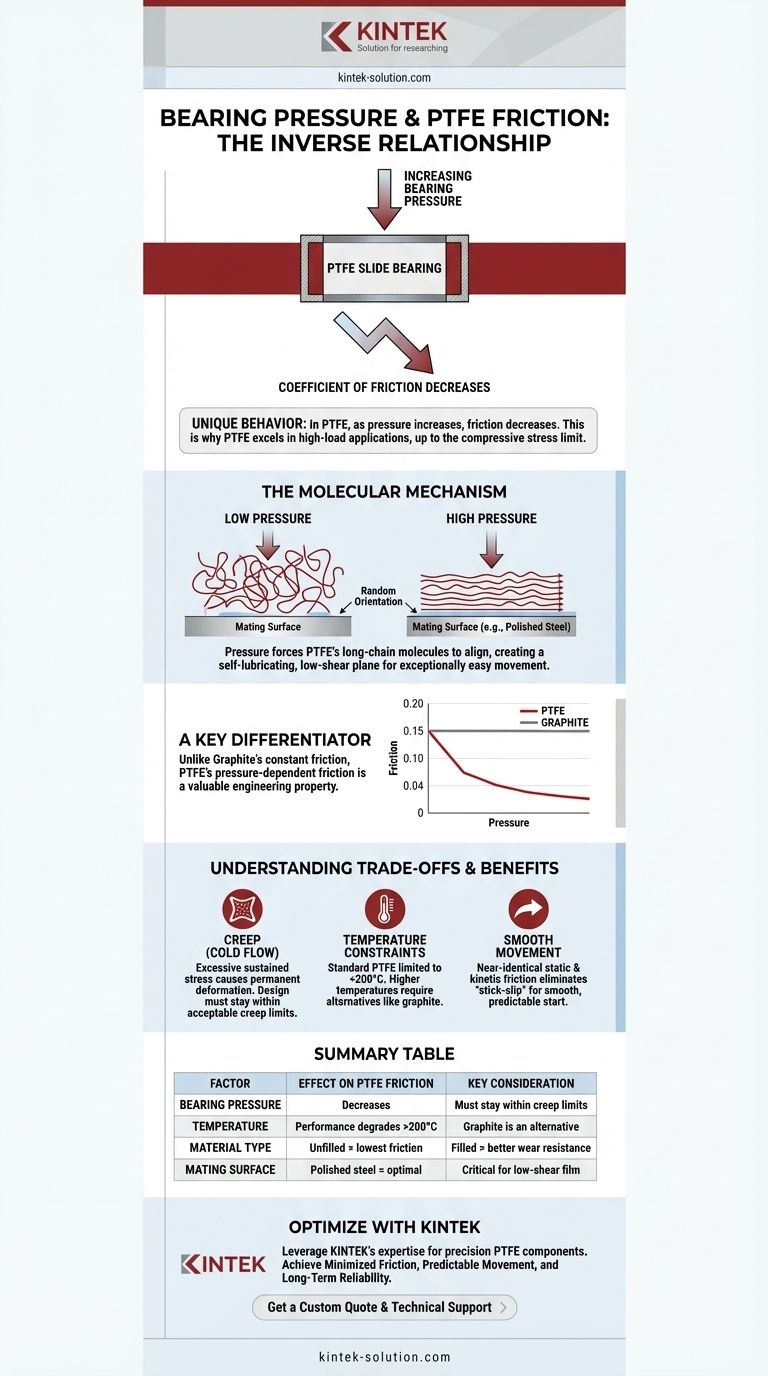

In PTFE slide bearings, the relationship is inverse: as bearing pressure increases, the coefficient of friction decreases. This unique behavior is a primary reason PTFE is specified for high-load applications like structural and bridge bearings. This effect continues until the material's compressive stress limit is approached.

The core principle to understand is that PTFE's molecular structure allows it to become "self-lubricating" under pressure. Higher stress forces the material's long-chain molecules to align in the direction of motion, creating an extremely low-shear plane that significantly reduces frictional resistance.

The Inverse Relationship: Why Pressure Reduces Friction

To properly design a sliding system with Polytetrafluoroethylene (PTFE), it's essential to understand the mechanism behind its unique frictional properties. Unlike many materials, applying more force makes it slicker.

The Molecular Mechanism of PTFE

PTFE is composed of long, linear polymer chains. Under low pressure, these chains are randomly oriented.

When significant pressure is applied, a thin layer of these molecules is drawn from the PTFE and transferred to the mating surface, orienting themselves in the direction of sliding. This creates a highly ordered, low-shear film that allows for exceptionally easy movement.

The Impact of Increasing Stress

The coefficient of friction is minimized when the stress on the PTFE is at its maximum allowable value.

This is because higher pressure improves the alignment and transfer of the molecular film, enhancing the self-lubricating effect. While PTFE has a very low baseline coefficient of friction (around 0.04), operating it under significant load is the key to achieving optimal performance.

A Key Differentiator from Other Materials

This behavior is in stark contrast to other common bearing materials.

For example, graphite's coefficient of friction remains relatively constant at approximately 0.15, regardless of the bearing pressure. This makes PTFE's pressure-dependent friction a distinct and valuable engineering property.

Understanding the Trade-offs and Limitations

While high pressure is beneficial for reducing friction, it must be balanced against the material's physical limitations. Pushing the material beyond its design limits can lead to premature failure.

The Critical Role of Creep

The most significant limitation is creep, also known as "cold flow." PTFE can permanently deform over time if subjected to excessive, sustained stress.

Therefore, the bearing must be designed so that the pressure minimizes friction while remaining well within the material's acceptable creep limits to ensure long-term structural integrity.

Temperature Constraints

Temperature significantly affects PTFE's performance and strength.

Standard PTFE configurations are generally limited to operating temperatures below 200°C. For applications involving higher heat, alternative materials like graphite (stable up to 400-500°C) must be considered, even though they come with a higher coefficient of friction.

The Advantage of Low Static Friction

A major benefit of PTFE is that its static and kinetic coefficients of friction are nearly identical.

This eliminates the "stick-slip" phenomenon common in other systems, where a higher initial force is needed to start the movement. With PTFE, the transition from static to dynamic is exceptionally smooth, which is critical for sensitive structures.

Making the Right Choice for Your Application

Selecting and designing the right bearing requires balancing your primary engineering goal with these material properties.

- If your primary focus is achieving the lowest possible friction: Design the bearing to operate at its maximum safe stress level, use unfilled PTFE, and ensure the mating surface (typically stainless steel) is highly polished.

- If your primary focus is high-temperature performance: You must look beyond PTFE to materials like graphite, accepting the trade-off of a higher and more constant coefficient of friction.

- If your primary focus is smooth, predictable movement: PTFE is an outstanding choice due to its near-identical static and kinetic friction, which guarantees a smooth start without jerking.

By understanding these principles, you can engineer a sliding system that is not only efficient but also predictable and reliable for its intended lifespan.

Summary Table:

| Factor | Effect on PTFE Friction | Key Consideration |

|---|---|---|

| Bearing Pressure | Decreases coefficient of friction | Must stay within creep limits |

| Temperature | Performance degrades above ~200°C | Graphite is an alternative for high heat |

| Material Type | Unfilled PTFE offers lowest friction | Filled compounds trade friction for wear resistance |

| Mating Surface | Polished stainless steel optimizes performance | Critical for forming the low-shear film |

Optimize Your PTFE Bearing Design with KINTEK

Understanding the precise relationship between pressure and friction is key to a high-performance sliding system. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom bearings—for the semiconductor, medical, laboratory, and industrial sectors.

We can help you leverage PTFE's unique properties to achieve:

- Minimized Friction: Design bearings to operate at optimal stress levels for superior, self-lubricating performance.

- Predictable Movement: Eliminate stick-slip with PTFE's near-identical static and kinetic friction.

- Long-Term Reliability: Balance high pressure with material limits to prevent creep and ensure durability.

Whether you need a prototype or high-volume production, our expertise in custom PTFE fabrication ensures your application performs reliably. Contact us today to discuss your specific requirements and let our engineers help you find the perfect solution.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support