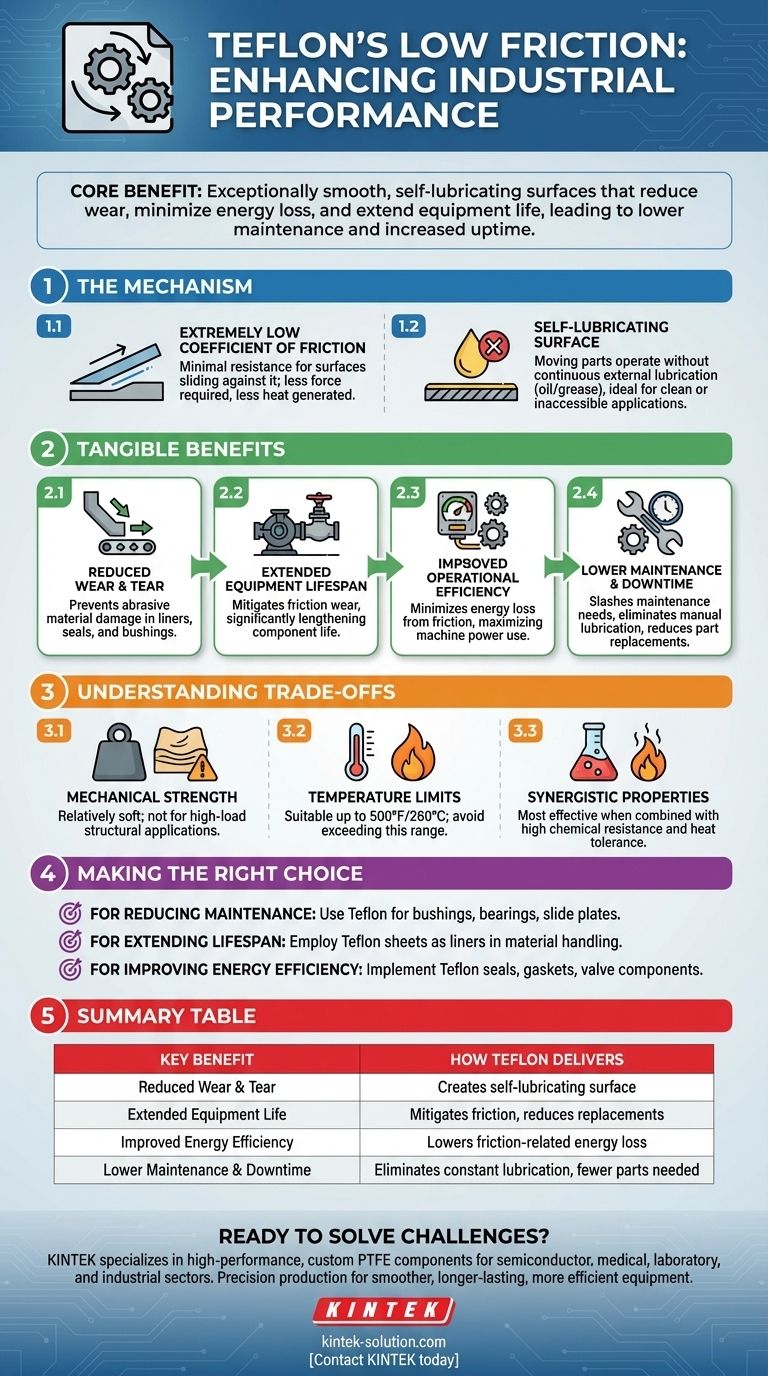

At its core, the low friction property of Teflon (PTFE) plastic sheets enhances industrial performance by creating exceptionally smooth, self-lubricating surfaces. This dramatically reduces wear and tear on moving parts, minimizes energy loss, and extends the operational life of machinery, which translates directly into lower maintenance costs and increased uptime.

The true value of Teflon's low friction isn't just its "slipperiness," but its ability to solve the core industrial challenges of mechanical wear, energy inefficiency, and constant maintenance. It functions as a permanent lubricating layer where traditional oils and greases would fail or be impractical.

The Mechanism: How Low Friction Works

The performance benefits of Teflon plastic sheets originate from the unique molecular structure of Polytetrafluoroethylene (PTFE).

An Extremely Low Coefficient of Friction

Teflon possesses one of the lowest coefficients of friction of any solid material. This means that surfaces slide against it with minimal resistance.

In practical terms, less force is required to move components, and less heat is generated from friction during operation.

A Self-Lubricating Surface

The material's properties allow moving parts to operate smoothly without the need for continuous external lubrication like oil or grease.

This "self-lubricating" characteristic is critical in applications where adding lubricants is difficult, undesirable (as in food processing), or would attract contaminants.

Translating Low Friction into Tangible Benefits

This fundamental property creates a cascade of positive effects that improve an entire industrial process.

Drastically Reduced Wear and Tear

In high-speed or continuous material handling systems, Teflon liners prevent abrasive materials from wearing down chutes, hoppers, and conveyor beds.

This same principle applies to mechanical components like seals and bushings, where Teflon minimizes friction between moving parts, preventing their degradation over time.

Extended Equipment Lifespan

By mitigating the primary cause of mechanical failure—wear from friction—Teflon directly extends the life of equipment.

Components like pump seals and valve seats last significantly longer, reducing the frequency of costly replacements.

Improved Operational Efficiency

In systems like pumps and valves, friction creates energy loss. Minimizing this friction means that less energy is wasted.

This leads to more efficient operation, as more of the machine's power is used for its intended task rather than to overcome internal resistance.

Lower Maintenance Costs and Downtime

The combination of reduced wear and self-lubrication slashes maintenance requirements.

Fewer parts need replacing, and the labor associated with lubrication is eliminated, leading to less downtime and significant long-term cost savings.

Understanding the Trade-offs

While its low friction is a powerful asset, it's essential to understand the context and limitations of PTFE.

Mechanical Strength

PTFE is a relatively soft material. It is not designed for high-load structural applications where rigidity and compressive strength are the primary requirements.

It excels as a lining, seal, or bearing surface, but not as a primary structural component.

Temperature Limits

Although it has a high-temperature tolerance (up to 500°F/260°C), it is not suitable for applications that exceed this limit.

Engineers must operate within its specified thermal range to ensure the material remains stable and effective.

Synergistic Properties

The true power of Teflon is often realized when its low friction is combined with its other key properties: high chemical resistance and heat tolerance.

This combination allows it to provide smooth operation even in highly corrosive or high-temperature environments where other materials would quickly fail.

Making the Right Choice for Your Goal

To apply this effectively, match the material's properties to your specific operational challenge.

- If your primary focus is reducing maintenance costs: Utilize Teflon for bushings, bearings, and slide plates to eliminate the need for frequent manual lubrication.

- If your primary focus is extending equipment lifespan: Employ Teflon sheets as liners in material handling equipment to protect expensive machinery from abrasive wear.

- If your primary focus is improving energy efficiency: Implement Teflon seals, gaskets, and valve components to minimize energy loss from friction in fluid and gas systems.

Ultimately, leveraging Teflon's unique properties is a strategic decision that enhances the reliability and efficiency of your entire operation.

Summary Table:

| Key Benefit | How Teflon Delivers |

|---|---|

| Reduced Wear & Tear | Creates a self-lubricating surface that minimizes abrasive damage to machinery. |

| Extended Equipment Life | Mitigates the primary cause of mechanical failure, reducing replacement frequency. |

| Improved Energy Efficiency | Lowers energy loss from friction in systems like pumps and valves. |

| Lower Maintenance & Downtime | Eliminates need for constant lubrication and reduces part replacements. |

Ready to solve your toughest friction, wear, and chemical resistance challenges?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment runs smoother, lasts longer, and operates more efficiently.

Contact KINTEK today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts